Method for replacing ladle turret rotary arm of continuous casting machine

The technology of a large-bag rotary table and a replacement method is applied in the field of replacing the rotary arm of a large-bag rotary table of a continuous casting machine, which can solve the problems of time-consuming and labor-intensive, and achieve the effect of good balance effect, reducing influence and improving maintenance efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

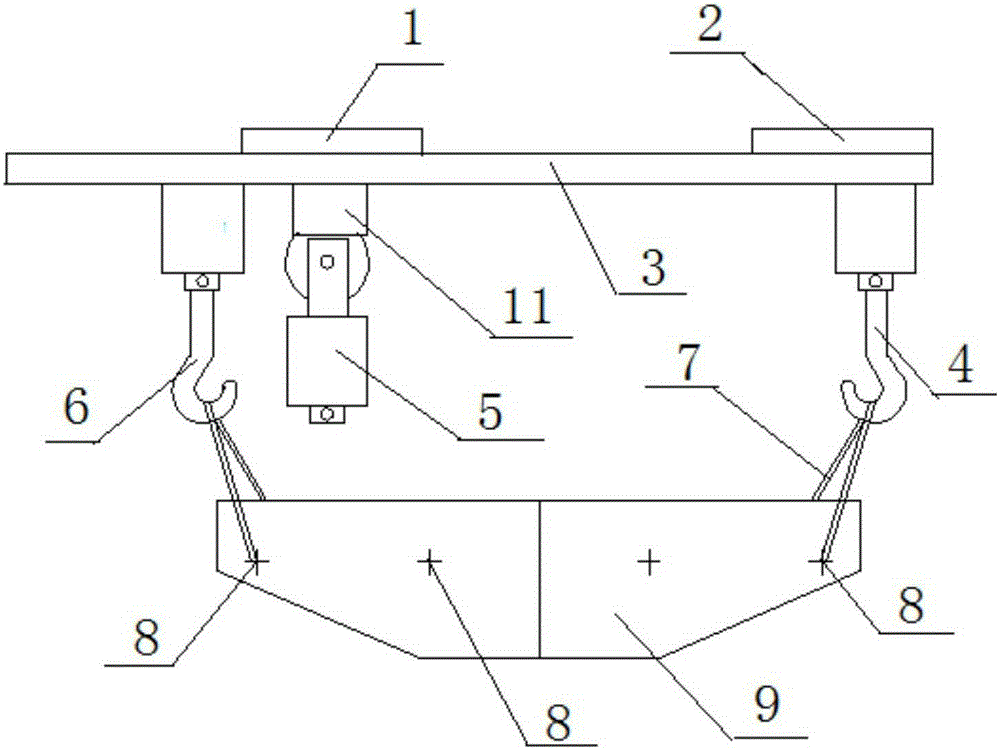

[0041] The total weight of the rotary arm of the ladle rotary table of the continuous casting machine in this embodiment is 44T. The difficulty of this overhaul lies in hoisting the rotary arm, transporting it in the air, and landing it on the ground. Since the slewing arm of the bale turntable is in the dead angle position of the driving, it is impossible to complete the lifting work with a one-span driving. This hoisting method adopts the method of hoisting the slewing arm at the same time with two-span cranes for hoisting and installation. Hoisting traction rope 7 is a steel wire rope, specification: 4 wire ropes of φ 39mm*9 meters, and antiskid and protection measures are done well. The replacement steps are:

[0042] A. Installation of fixing parts: Evenly distribute and detachably fix the fixing parts 8 in the length direction of the rotary arm 9 of the ladle rotary table of the continuous casting machine;

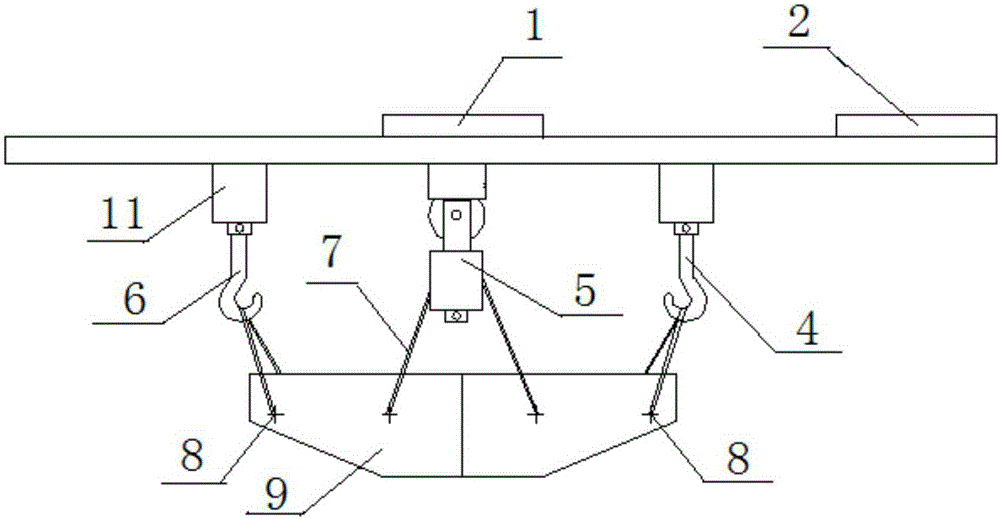

[0043] B. Hoisting between two spans: such as figure 1 As sh...

Embodiment 2

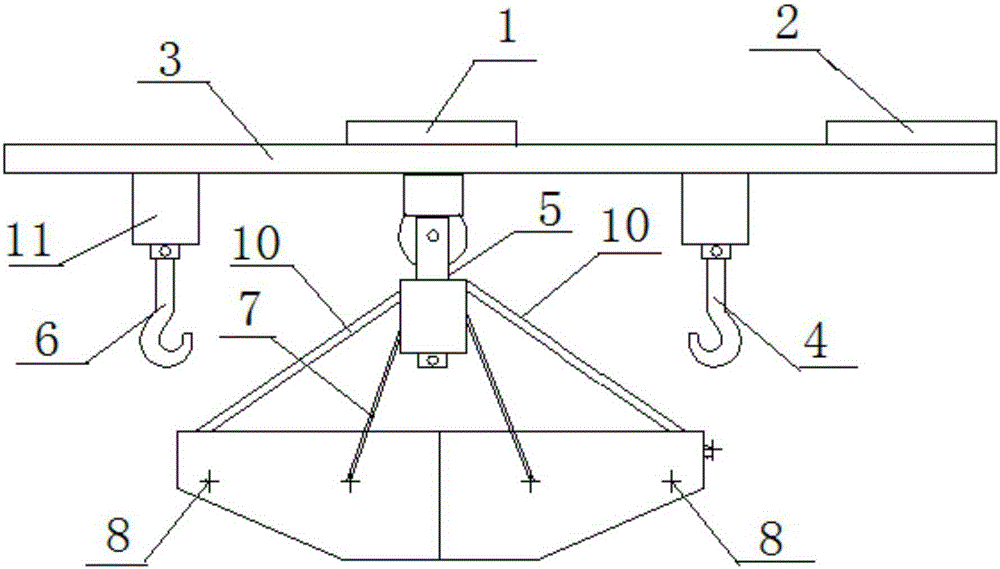

[0050] The basic steps of the method for replacing the rotary arm of the ladle turret of the continuous casting machine in this embodiment are the same as those of Embodiment 1. The improvement is that in step A, the fixing part 8 is a D-shaped lifting lug, which is rotated on the ladle turret of the continuous casting machine. There are four on the front and back sides of the arm 9, and they are symmetrically arranged front and back. The D-shaped lifting lug structure is convenient for lifting and translation, and is simple and practical. ,Such as Figure 4 As shown, when the main hook 5 of the molten steel straddling vehicle is in use, the lower hook is disassembled, leaving only the balance beam 51 of the main hook of the molten steel straddling vehicle, which effectively prevents the lifting stroke of the main hook of the molten steel straddling vehicle from being affected by it. The car owner's hook 4 moves forward, backward, left and right on the guide rail 3 through the...

Embodiment 3

[0052] The basic steps of the method for replacing the rotary arm of the ladle rotary table of the continuous casting machine in this embodiment are the same as those in Embodiment 2, and the improvement is that in step C, the auxiliary hook 6 of the molten steel straddle carriage and the main hook 4 of the continuous casting straddle carriage are passed through the traveling mechanism 11 in the The guide rail 3 translates back and forth, left and right, and the two-span cranes are synchronously translated by the PLC to control the traveling mechanism 11 to move the rotary arm 9 of the ladle turntable of the continuous casting machine to the position directly below the main hook 5 of the molten steel straddle carriage. In step E, the balancing mechanism 10 is a 10-ton electric hoist; the PLC controls the traveling mechanism 11 to perform precise translation, and the positioning effect is good, so that the molten steel cross-travel hook 6 and the continuous casting cross-travel m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com