Practical operation examine analog machine of industrial boiler

A technology of industrial boilers and simulators, which is applied in the field of simulators, can solve problems such as the inability of boiler personnel to troubleshoot operations and emergency treatment, the inability to confirm the operation ability of boiler personnel, and the inability to train and assess boiler personnel, so as to increase the perceptual knowledge of trainees , reduce the boiler accident rate, and improve the operation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

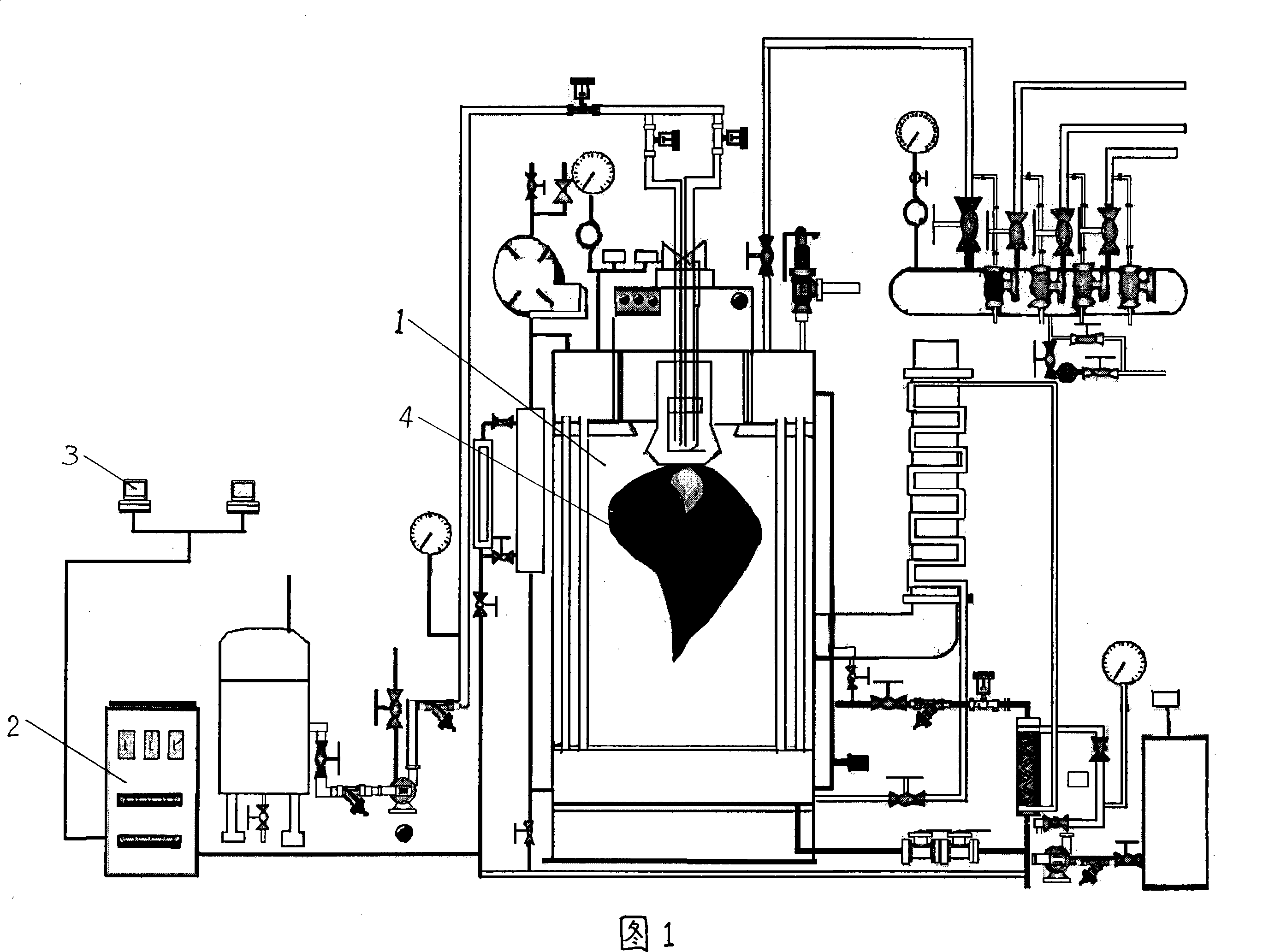

[0026] The industrial boiler practical operation training and assessment simulator shown in Figure 1 is mainly composed of a simulation prototype 1, a control system 2 and a computer system 3. There are simulated flame 4 etc. in the simulation production, and there are multiple control points for training and assessment on the body. The control points are the parts where the working parameters of the boiler can be operated in actual operation, such as water level gauge, pressure gauge, water inlet valve, water outlet Valves, etc., the control points are equipped with operable parts and sensor-type signal acquisition devices. The operating parts send out control point signals due to operation, and the sensors collect the control point signals, and then transmit the control point signals to the control system through cables. The signal is processed by the control system and then transmitted to the computer system. The computer system processes the received signal and responds acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com