Automatic detection line and detection method of carbon fiber gas bottle

A carbon fiber gas cylinder, automatic detection technology, applied in the combination of methods to dry solid materials, by detecting the appearance of fluid at the leakage point, measuring devices and other directions, it can solve the problems of manual screwing, inconvenient control, poor use effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

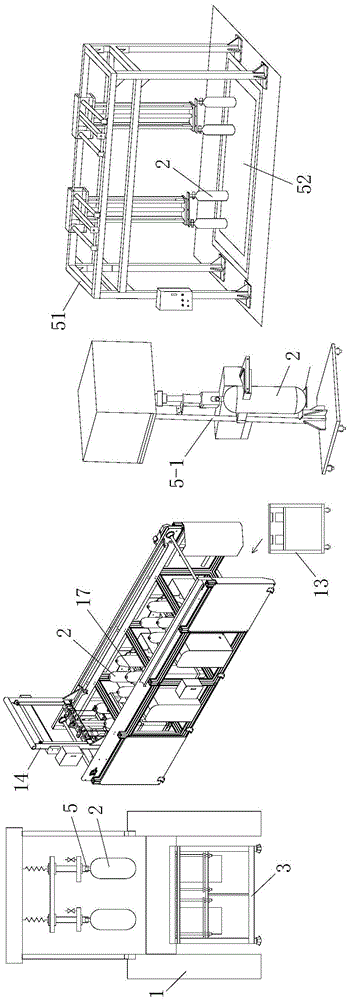

[0166] Such as figure 1 The shown automatic detection line for carbon fiber gas cylinders includes a hydraulic test device, a hydraulic auxiliary test device, a bottle valve loading and unloading machine and an air tightness test device arranged from front to back.

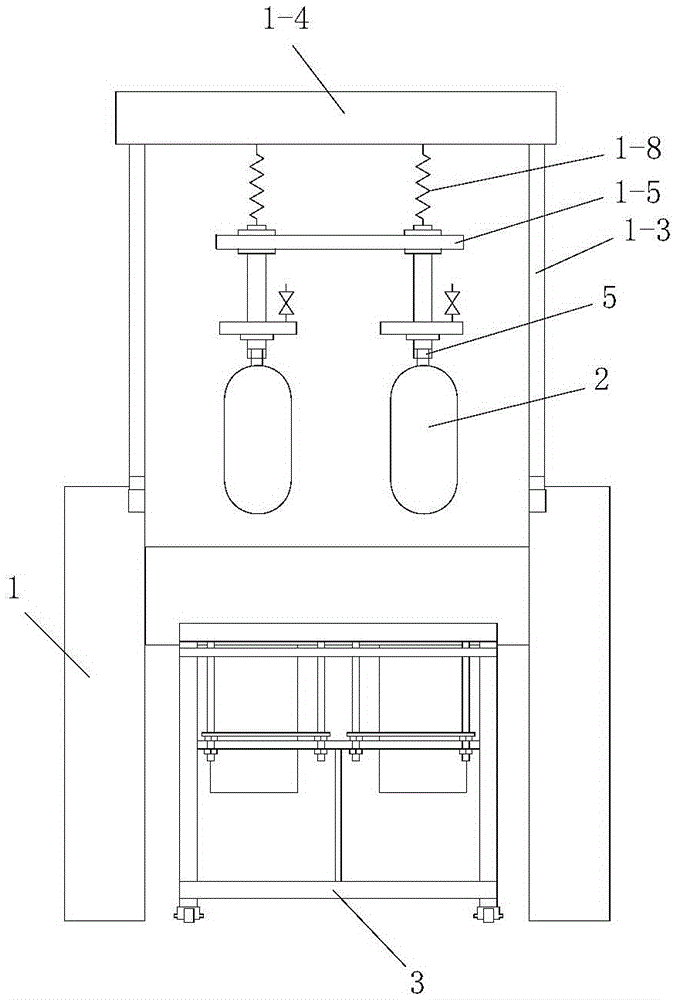

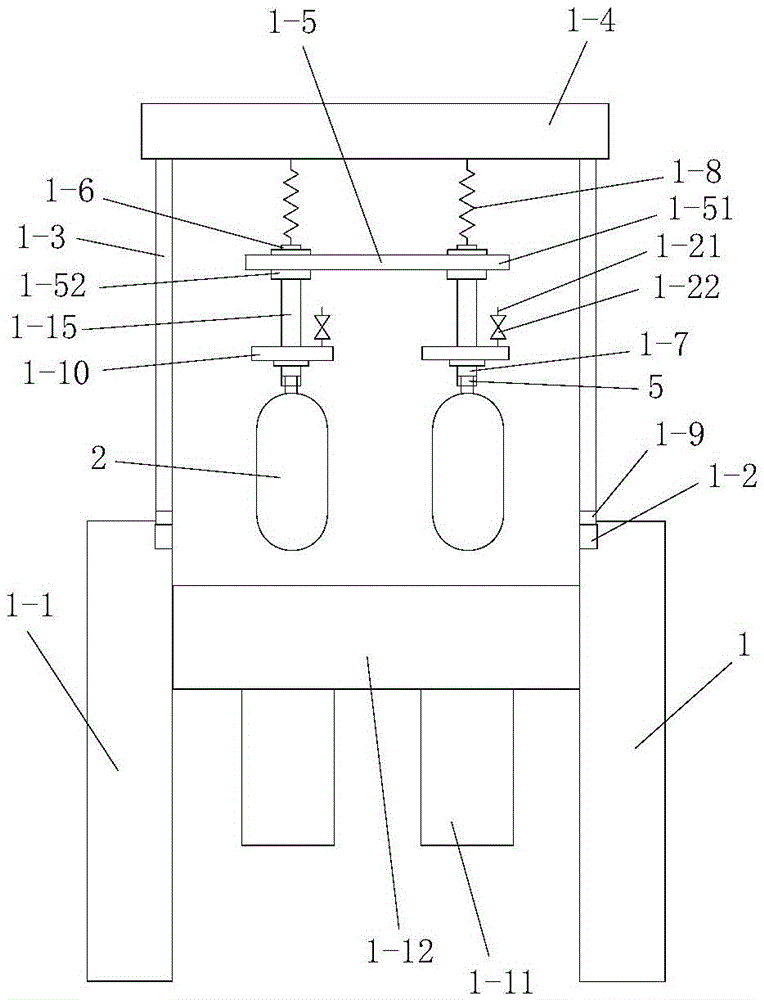

[0167] combine Picture 1-1 , the hydraulic testing device includes a test frame 1, a test console 4 positioned at one side of the test frame 1, a pressurizing device for pressurizing the gas cylinder 2 to be tested, and a test box installed on the test frame 1 And for a plurality of tested gas cylinders 2 to be stably placed and can be tested gas cylinders 2 to be moved to the test trolley 3 on the front side of the test frame 1, a plurality of said tested gas cylinders 2 mounted on the test trolley 3 are in the form of Lay out vertically. The gas cylinder 2 to be tested is a carbon fiber gas cylinder, and a sealing joint 5 is installed on the mouth of the carbon fiber gas cylinder.

[0168] The test frame 1 i...

Embodiment 2

[0415] In this embodiment, the carbon fiber gas cylinder detection line adopted is different from Embodiment 1 in that: the air tightness testing device is a trough type air tightness testing device 51; Figure 4-6 , Figure 4-7 and Figure 4-8 As shown, the trough-type air-tightness testing device 51 includes an excavated underground water tank 52, a vertical support frame 53 standing above the underground water tank 52, and a control box 56 installed on the vertical support frame 53 and The gas cylinder hoisting frame that a plurality of tested gas cylinders 2 are hoisted synchronously, the quantity of the gas cylinder hoisting frame is two and both of them are installed on the vertical support frame 53; A plurality of underwater surveillance cameras 54, a plurality of upper surveillance cameras 55 are installed above the underground water tank 52, a plurality of underwater surveillance cameras 54 and a plurality of upper surveillance cameras 55 are connected with the third...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com