Reactor thermal-hydraulic simulation testing apparatus and fluid dynamics characteristic simulation method

A simulation test, thermal hydraulic technology, applied in reactors, nuclear reactor monitoring, nuclear engineering, etc., can solve the problems of cumbersome process and affecting the efficiency of simulation tests, and achieve the effect of simple overall structure, low cost and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

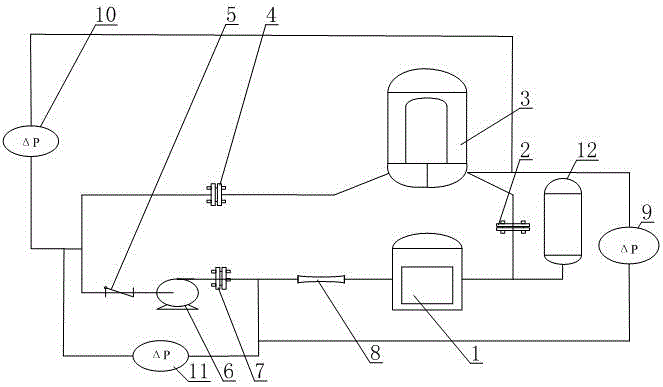

[0039] Such as figure 1 As shown, the reactor thermal-hydraulic simulation test device includes a reactor simulation body 1, a steam generator simulation body 3, and a main circulation pump 6. The inlet and outlet of the steam generator simulation body 3 are connected to the reactor simulation body 1 outlet and The inlet of the main circulating pump 6 is connected, and the outlet of the main circulating pump 6 is connected to the inlet of the reactor simulation body 1 through a pipeline. In this embodiment, the pipe between the inlet of the steam generator simulation body 3 and the outlet of the reactor simulation body 1 is provided with a hot section resistance regulator 2, and the pipe between the outlet of the steam generator simulation body 3 and the inlet of the main circulation pump 6 is provided There are a cold section resistance adjusting member 4 and a check valve 5, and the check valve 5 is located between the cold section resistance adjusting member 4 and the main ci...

Embodiment 2

[0067] This embodiment makes the following further restrictions on the basis of embodiment 1: This embodiment also includes a hot-end pressure difference transmitter 9, a cold-end pressure difference transmitter 10, and a pumping pressure difference transmitter 11. , Both the positive pressure ends of the hot section pressure difference transmitter 9 and the pump path pressure difference transmitter 11 are connected with the pipeline between the pump path resistance adjusting member 7 and the Venturi flowmeter 8, and the hot section pressure difference is transmitted Both the negative pressure ends of the cold section pressure difference transmitter 9 and the cold section pressure difference transmitter 10 are connected to the pipeline between the hot section resistance adjusting member 2 and the steam generator simulation body 3. The cold section pressure difference transmitter 10 has a positive pressure end and The negative pressure end of the pump path differential pressure t...

Embodiment 3

[0069] In order to facilitate adjustment of the reference pressure of the reactor simulation body 1, this embodiment further defines the following on the basis of Embodiment 1 or Embodiment 2: This embodiment also includes a regulator 12, wherein the regulator 12 and the reactor The outlet of the simulation body 1 is turned on.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com