Non-uniform electric heating nuclear fuel simulation rod

An electric heating and nuclear fuel technology, applied in the field of testing, can solve the problems of unsolved temperature measurement of electric heating rods, difficulty in ensuring the relative position of resistance wires and rods, low thermal efficiency, etc., and achieves rapid and large heat exchange, simple and compact structure design. , the effect of high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

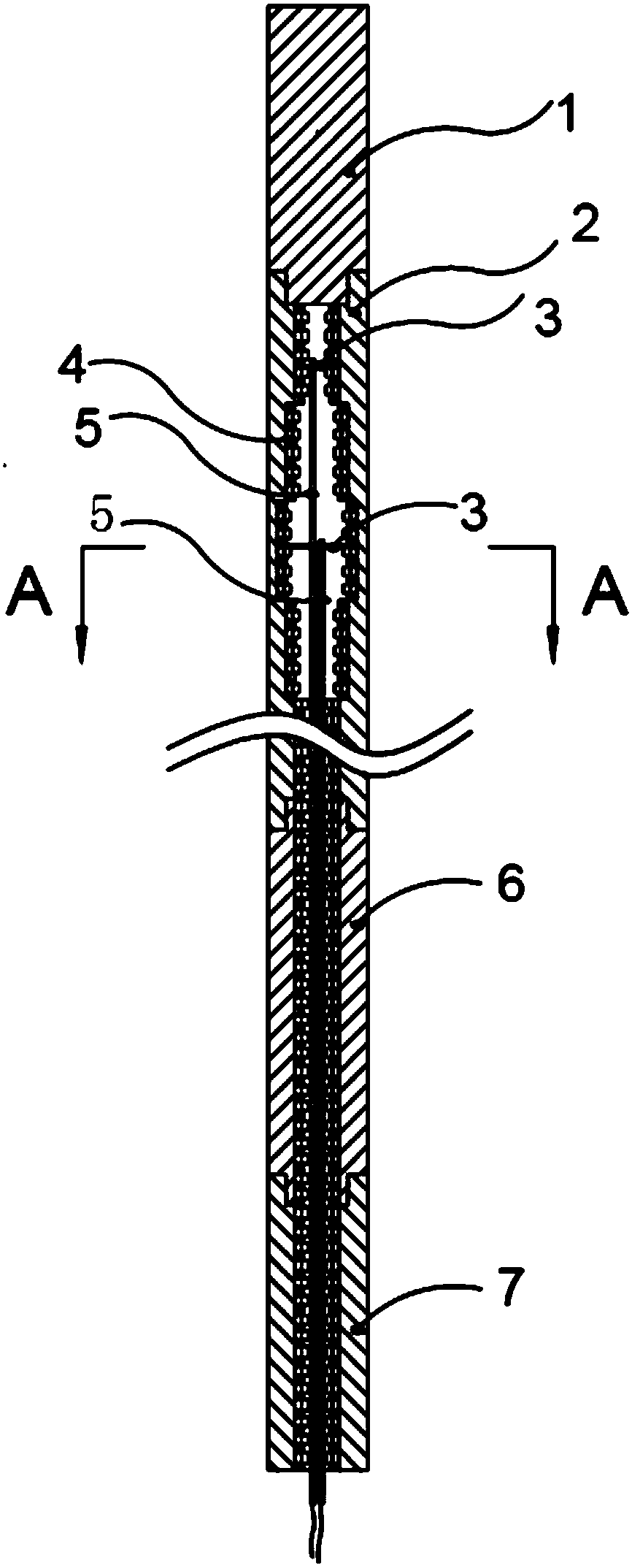

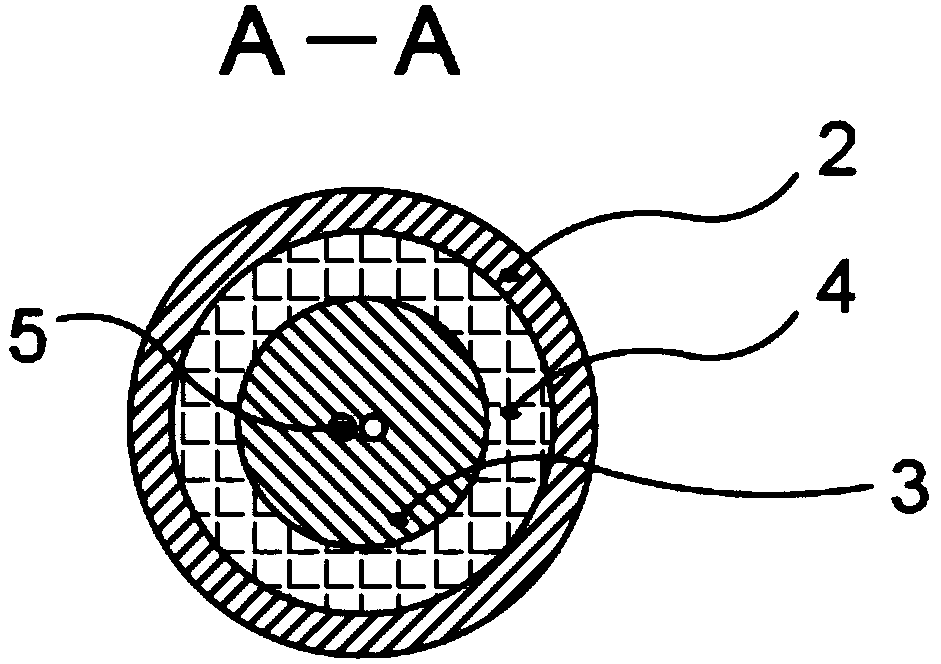

[0027] see figure 1 , a non-uniform electric heating nuclear fuel simulation rod is characterized in that: mainly comprising nickel rod 1, heating section 2, copper sheet 3, ceramic part 4, thermocouple 5, nickel tube 6, copper tube 7.

[0028] The nickel rod 1, the heating section 2, the nickel tube 6 and the copper tube 7 are sequentially connected from top to bottom to form a metal rod with a constant outer diameter. Its use environment can be high temperature and high pressure environment, and the working medium is deionized water.

[0029] The heating section 2 is a metal pipe with variable inner diameter. The upper end of the inner cavity of the heating section 2 is blocked by the nickel rod 1 , and the lower end of the inner cavity of the heating section 2 communicates with the inner cavity of the nickel tube 6 and the copper tube 7 .

[0030] The inner walls of the heating section 2 , the nickel tube 6 and the copper tube 7 have a ceramic layer, that is, a ceramic pi...

Embodiment 2

[0037] A critical heat flux test of a nuclear fuel assembly using the simulated rod described in Example 1 or a test of the thermal hydraulic performance of the fuel assembly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com