High efficiency absorption heat pump and methods of use

An absorption heat pump and absorbent technology, applied in the field of heat pumps, can solve the problems of lack of high efficiency and achieve the effect of increasing energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

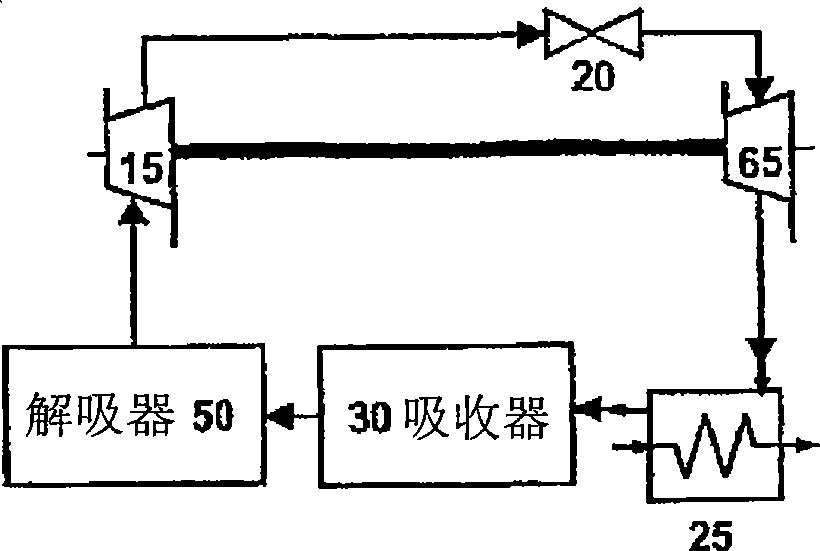

[0101] An absorption heat pump system in which the mode of operation for increasing the pressure from an initial pressure P0 to a second stage pressure P2 is selected from the group consisting of: (1) having a first adsorption or absorption stage with a pressure P1.sub .1, which contains a solid or liquid adsorbent; and a second adsorption or absorption stage having a pressure P2.sub.1, wherein the first stage adsorbent A1.sub.1 and the second stage liquid incompressible adsorbent A2. sub.1 combined and where P1.sub.1 is less than P2.sub.1, or (2) has a first stage of non-absorption compression stage containing a compressor or turbocharger where the first stage reduces the pressure from the initial pressure to P0.sub.2 is increased to the operating pressure P1.sub.2, and the second stage consists of an absorption stage containing solid or liquid adsorbent, where P1.sub.2 is smaller than P2.sub.2.

example 2

[0103] Example 1 further consists of a third stage to further increase the pressure, where the means of pressure increase comprises a non-absorption compression stage (ie, conventional compressor, turbocharger, etc.) or an absorption pumping stage.

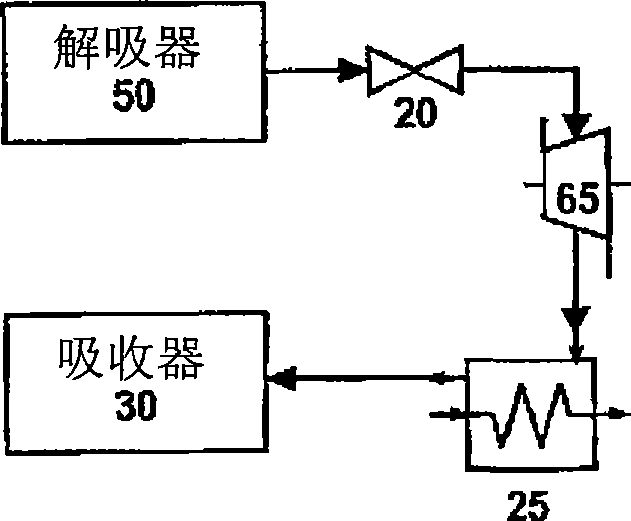

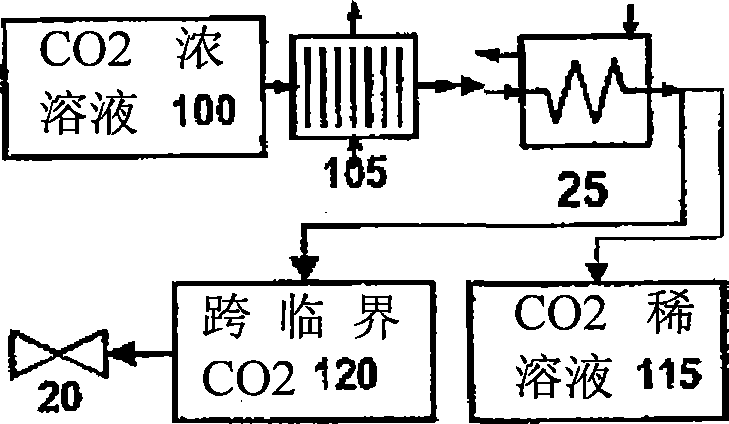

[0104] refer to Figure 12 , the desorbed refrigerant from the desorber 50, wherein the refrigerant is subsequently processed in at least one post-desorption process stage selected from reaction chemistry (including enzyme chemistry, fermentation chemistry), component extraction, The group consisting of supercritical combustion and combinations thereof in which the combined mechanical to electrical energy (E.sub.1) ratio required to increase the working fluid pressure to the operating pressure (P1) is reduced by compressing the compressible portion of the working fluid The combined mechanical and electrical energy (E.sub.2) required to increase the working fluid pressure to the operating pressure (P1) is at least 10% lower. This ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com