Adjustable charge-discharge type high temperature and high pressure helium gas experimental system and method

A high-temperature, high-pressure, charge-discharge technology, applied in the field of fusion reactor helium cooling, thermal hydraulics, can solve problems such as leakage and single experimental conditions, increase system components and costs, and meet the needs of different experimental conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

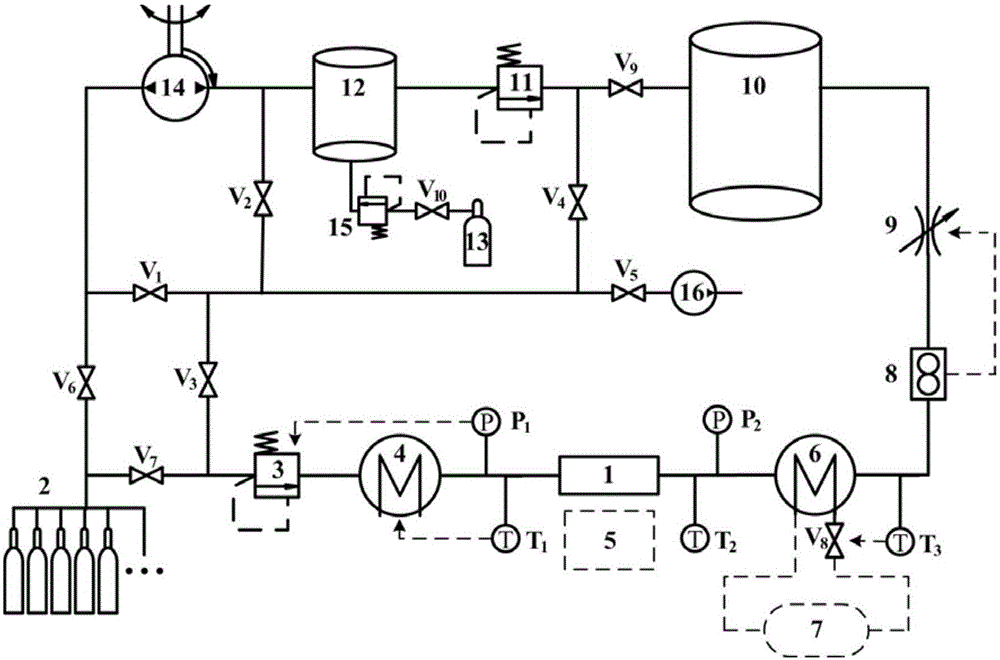

[0018] Specific embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail. The specific embodiment of the present invention adopts the schematic diagram of the adjustable high-temperature and high-pressure helium experimental system shown in the accompanying drawings.

[0019] In the present invention, the gas is supplied by a high-pressure helium cylinder group, decompressed to the required pressure through a pressure-reducing valve, the pressure-reducing valve is used for closed-loop control by a pressure transmitter, the helium is heated by an electric heater, and the temperature transmitter is used to The heating power of the electric heater is controlled in a closed loop, and the opening and closing degree of the control valve is adjusted by the difference between the set flow value and the flow meter, and the helium gas with the rated pressure, temperature and fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com