Airtight plugging device and method for sampling pipeline

A sampling pipeline and air-sealing technology, which is applied in the direction of measuring devices, fluid tightness testing, pipe components, etc., can solve the problems of shortened pipeline length, time-consuming and labor-intensive, low safety, etc., and achieve high safety, Easy to operate, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

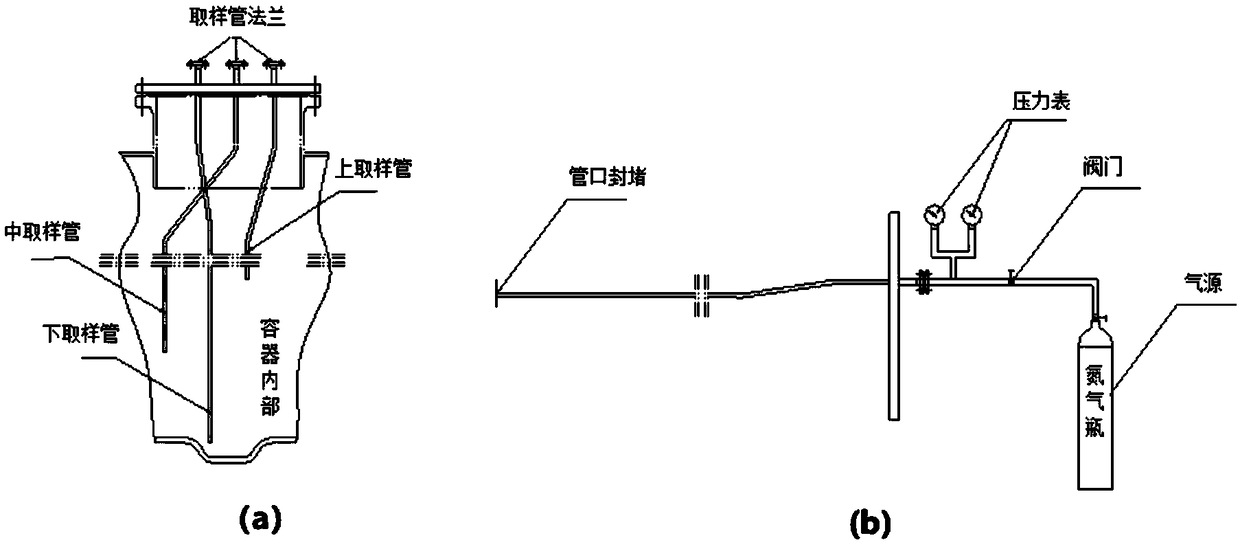

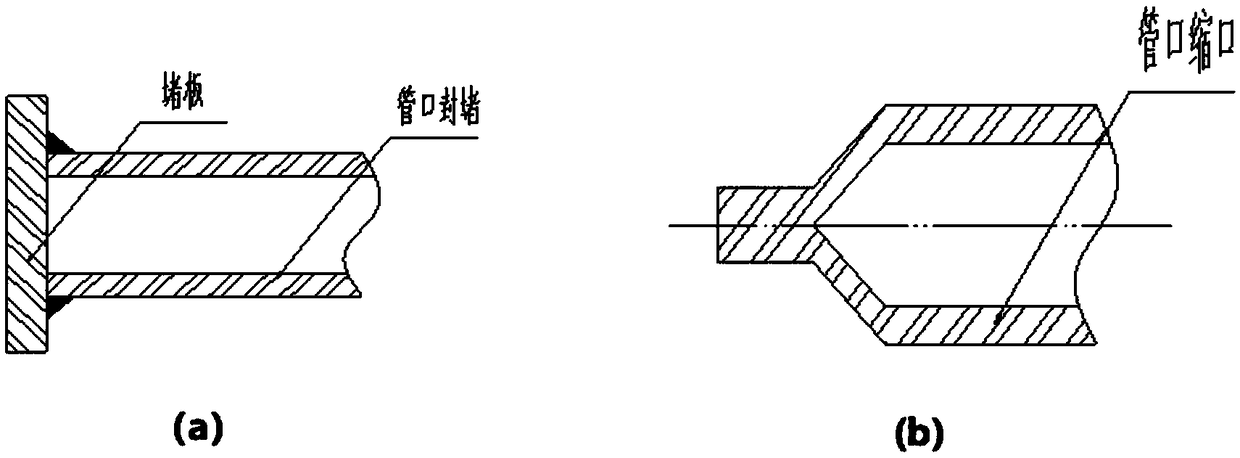

Problems solved by technology

Method used

Image

Examples

Embodiment 1

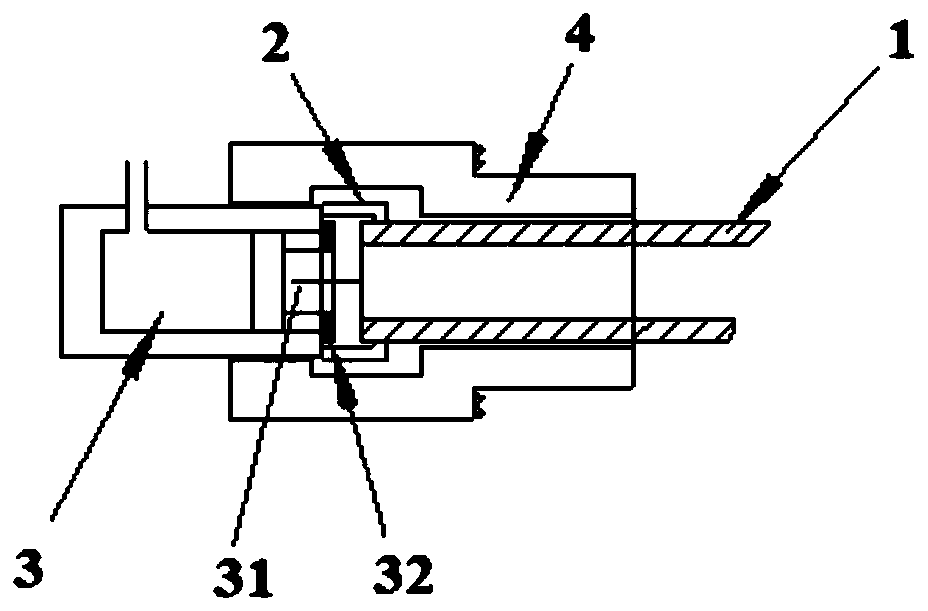

[0033] like Figure 3 to Figure 4 As shown, the present embodiment provides a sampling pipeline air-tight sealing device, which is used to seal the nozzle of the sampling pipeline 1, including a ferrule 2, an oil cylinder 3 and a drill chuck 4; one end of the ferrule 2 Connect the oil cylinder 3, the other end is set on the nozzle of the sampling pipeline 1, one end of the drill chuck 4 is sleeved on the outer wall of the oil cylinder 3, and the other end of the drill chuck 4 is used to fasten the sample near the nozzle of the sampling pipeline 1 On the outer wall of the pipeline 1; the ferrule 2, the oil cylinder 3 and the drill chuck 4 are coaxially arranged, and the drill chuck 4 can lock the oil cylinder 3, the ferrule 2 and the sampling pipeline 1. The ferrule 2 in this embodiment , each parts of oil cylinder 3 and drill chuck 4 are conventional parts. Through the above-mentioned technical scheme, the present invention is easy to operate and high in efficiency; the oil c...

Embodiment 2

[0038] This embodiment provides a method for air-tight sealing of the sampling pipeline. The method adopts a sampling pipeline air-sealing device to air-tightly seal the sampling pipeline, and specifically includes the following steps:

[0039] Step 1: Put the drill chuck on the outer wall of the sampling pipeline;

[0040] Step 2: Put one end of the through hole of the ferrule on the oil cylinder, and position the ferrule axially through the annular limit protrusion, and the other end of the ferrule is set on the outer wall of the sampling pipe mouth and screw clamped;

[0041] Step 3: Then move the drill chuck axially to the outside of the oil cylinder, ferrule and sampling pipe mouth; tighten the thread pairs at both ends of the drill chuck respectively, so that one end of the drill chuck clamps the oil cylinder, and the other end clamps the sample pipeline nozzle;

[0042] Step 4: pressurize the oil cylinder, and the piston rod drives the sealing gasket to extend until th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com