Pneumatic wheel brake for a vehicle

A wheel brake, vehicle technology, applied in the direction of brakes, brake types, drum brakes, etc., to achieve the effect of avoiding power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

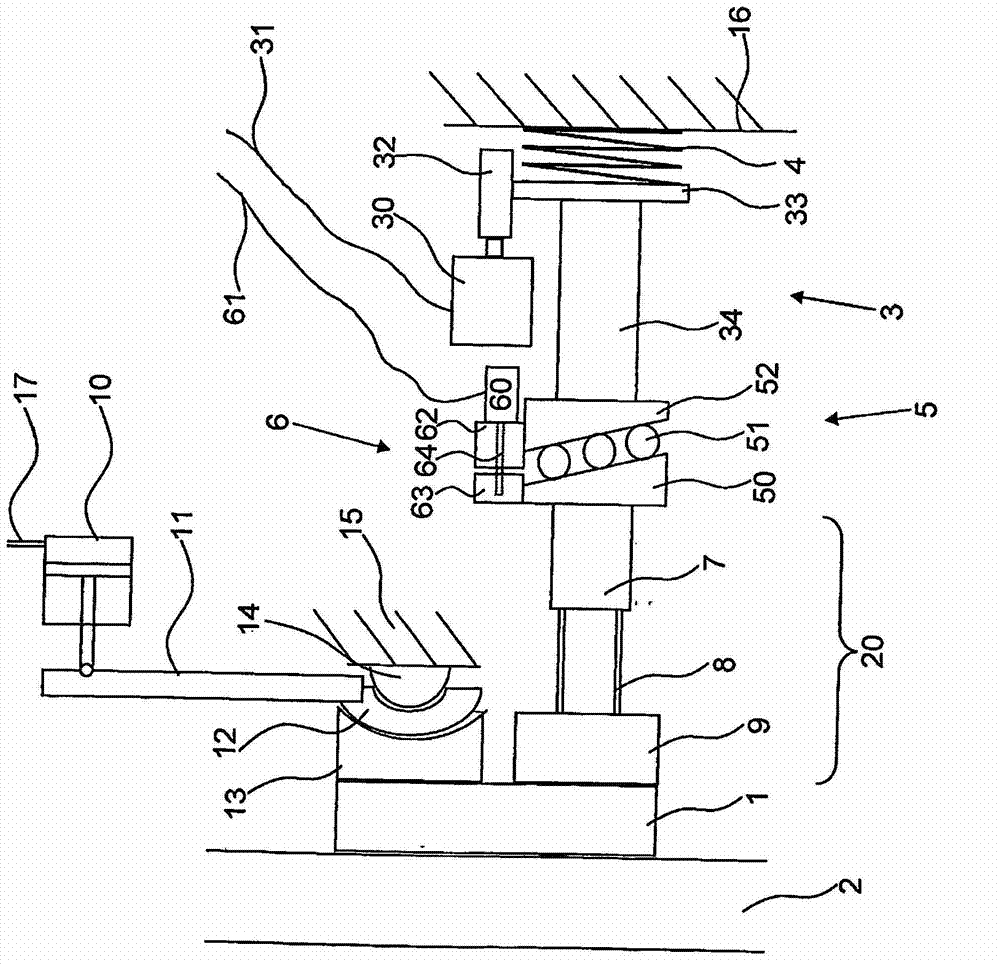

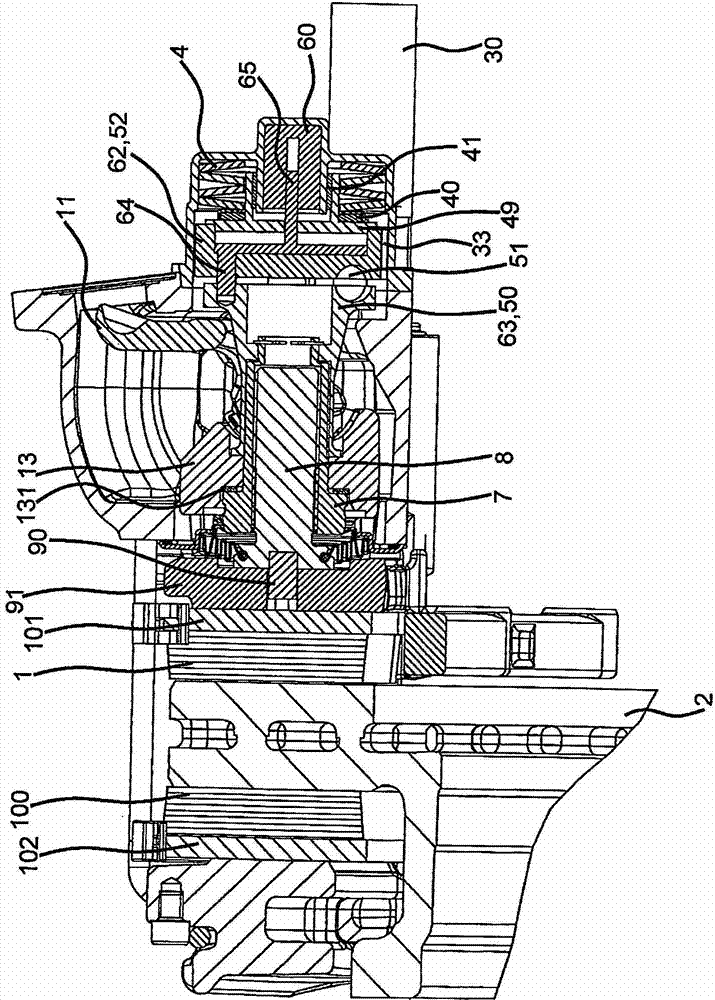

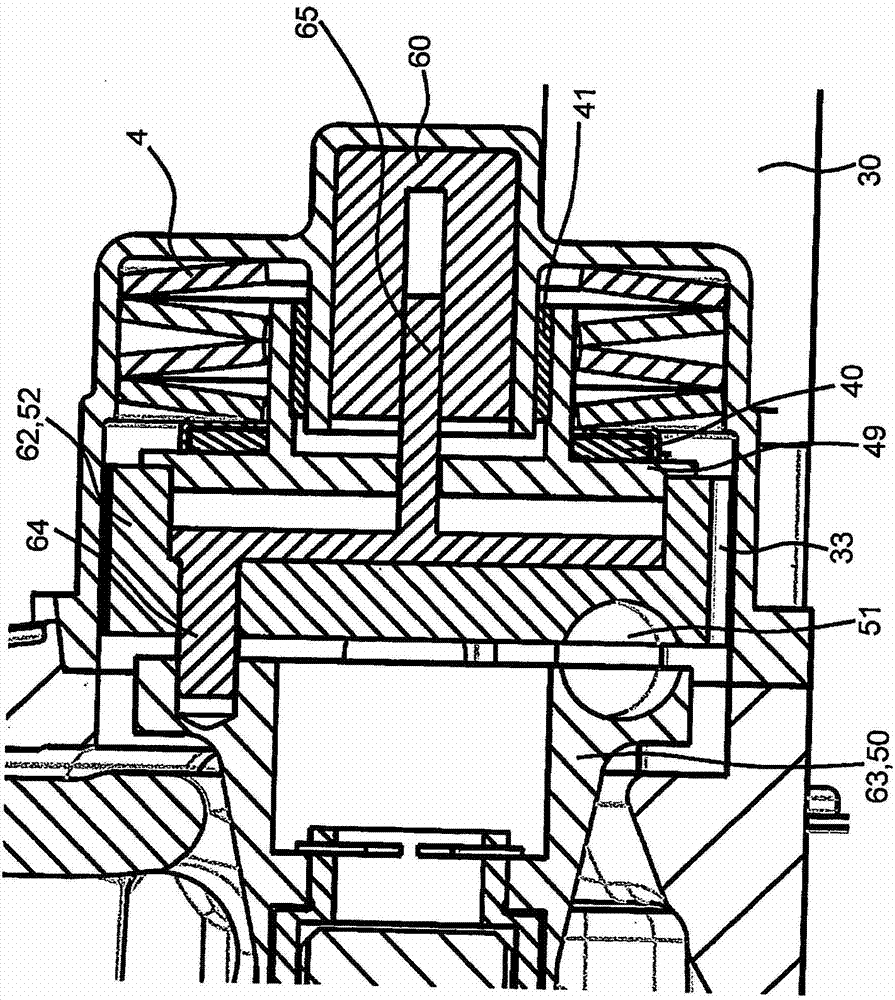

[0036] figure 1 A pneumatic wheel brake for a vehicle is shown in a very schematic diagram form. A compressed air cylinder 10 and a pressing device 20 connected to the compressed air cylinder 10 and capable of being manipulated by the compressed air cylinder 10 are shown. The hold-down device 20 has a brake lever 11, which has an operating element 12 provided with an operating contour at its end opposite to the point of action of the compressed air cylinder 10, which can be used for example with an eccentric or camshaft Form to construct. The actuating element 12 acts on a first pressure piece 13 configured with a corresponding relative profile, which pressure piece finally acts on the first brake element in the form of the brake lining 1. The actuating element 12 is supported rearward via a support element 14 on a component fixed to the housing of the wheel brake (for example, the brake cover 15).

[0037] By the manipulation of the compressed air cylinder 10 caused by filling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com