Filling and sealing technique for stranded elastic contact pin micro-rectangular electric connector

A technology of elastic pins and electrical connectors, which is applied in the direction of line/collector parts, connections, dustproof/splashproof/leakproof/waterproof/fireproof connections, etc., which can solve the problem of medium pressure resistance and unfavorable miniaturization products Sealing, airtight influence and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

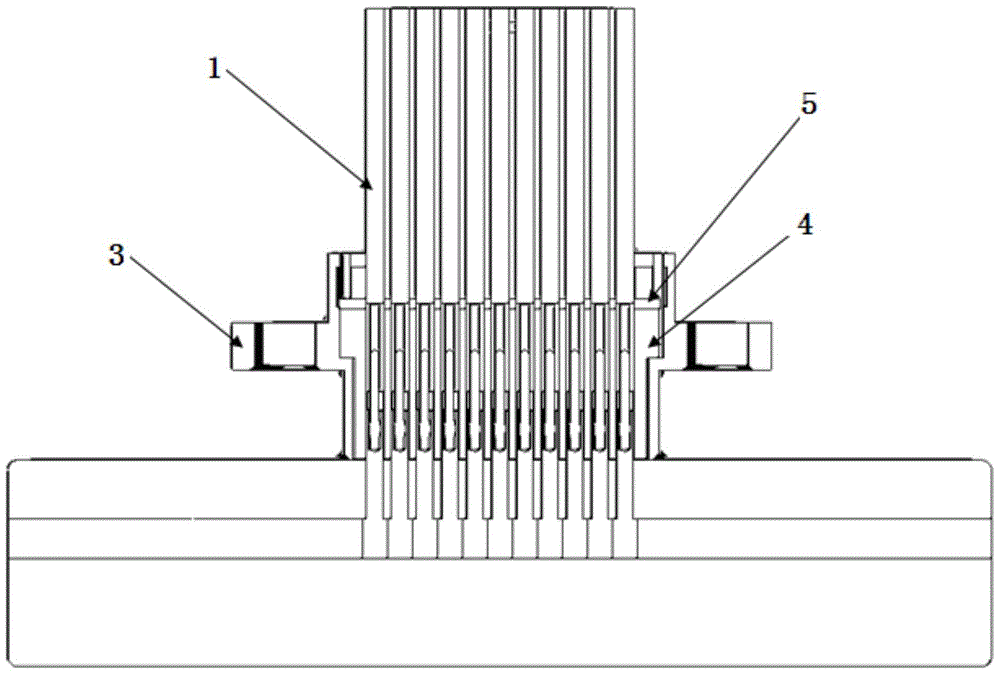

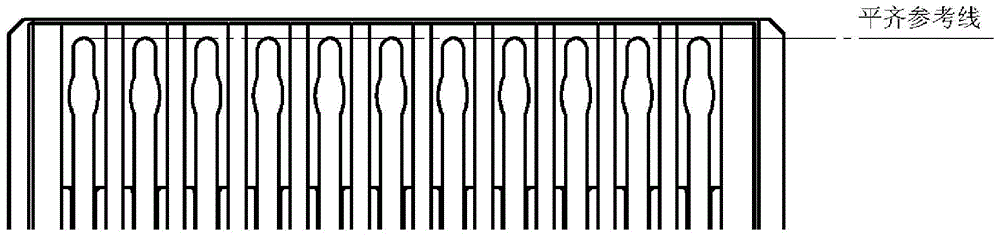

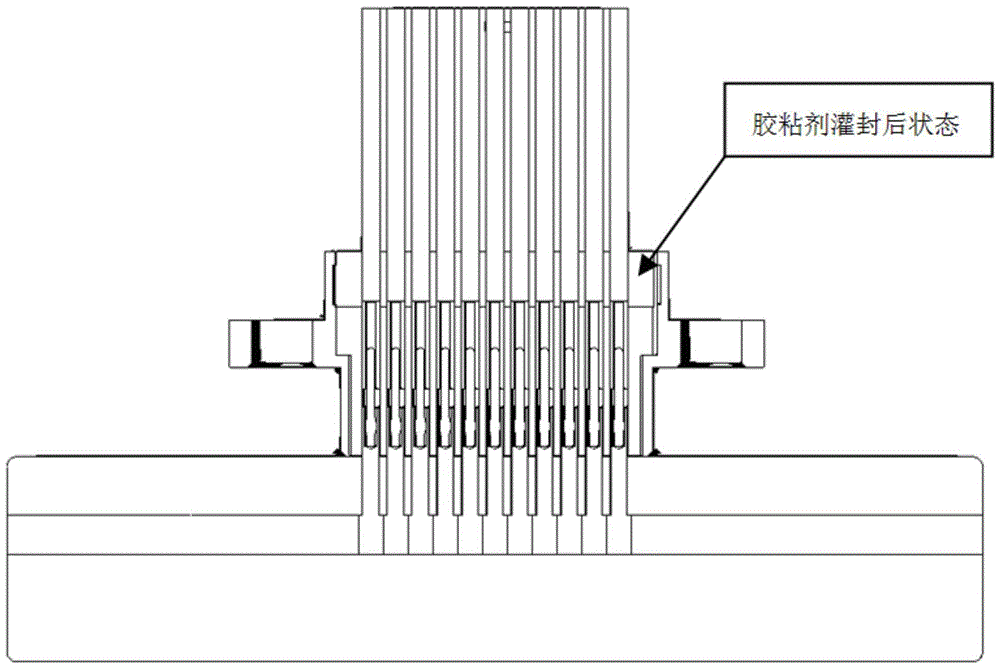

[0032] The steps of the potting process method for the micro-rectangular electric connector with stranded elastic pins are as follows:

[0033] ① Preparation of adhesive: Select DG-3S adhesive A and adhesive B of China Blue Chenguang Chemical Research and Design Co., Ltd., and prepare adhesive A and adhesive B at a mass ratio of 1.5 to 2:1. Use an electronic scale to accurately weigh a small amount of adhesive for cleaning In the glue mixing box, no sundries can be mixed into the glue; Stir continuously with a glue stick for 1 to 2 minutes until the glue is mixed evenly and the color of the glue is consistent;

[0034] ②Insulator fixed potting: put the insulator into the shell until it is assembled in place, and apply adhesive on the edge of the gap between the end face of the insulator and the shell, so that the glue can fill the gap, and the glue cannot stick to the holes and overflow of the insulator to the butt end face;

[0035] ③Primary curing: natural curing at room te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com