Multiscale reactor core thermal hydraulic analysis method

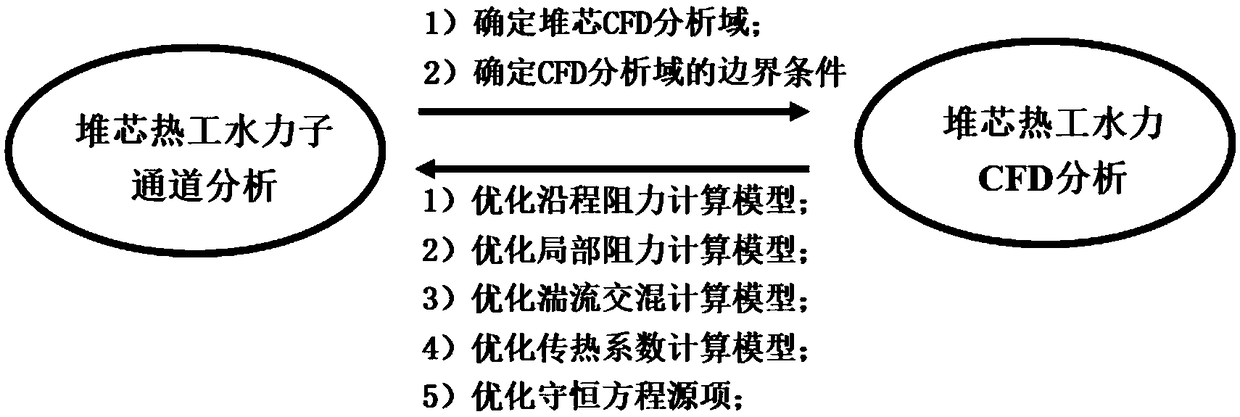

A multi-scale analysis, thermal-hydraulic technology, applied in special data processing applications, instruments, electrical and digital data processing, etc., it can solve the problem that the sub-channel program analysis is not as fine as CFD analysis, and it cannot analyze the core cell-scale regional flow. Field distribution information, calculation and analysis dependencies, etc., to ensure efficiency, avoid waste, and improve applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following examples describe the present invention in more detail.

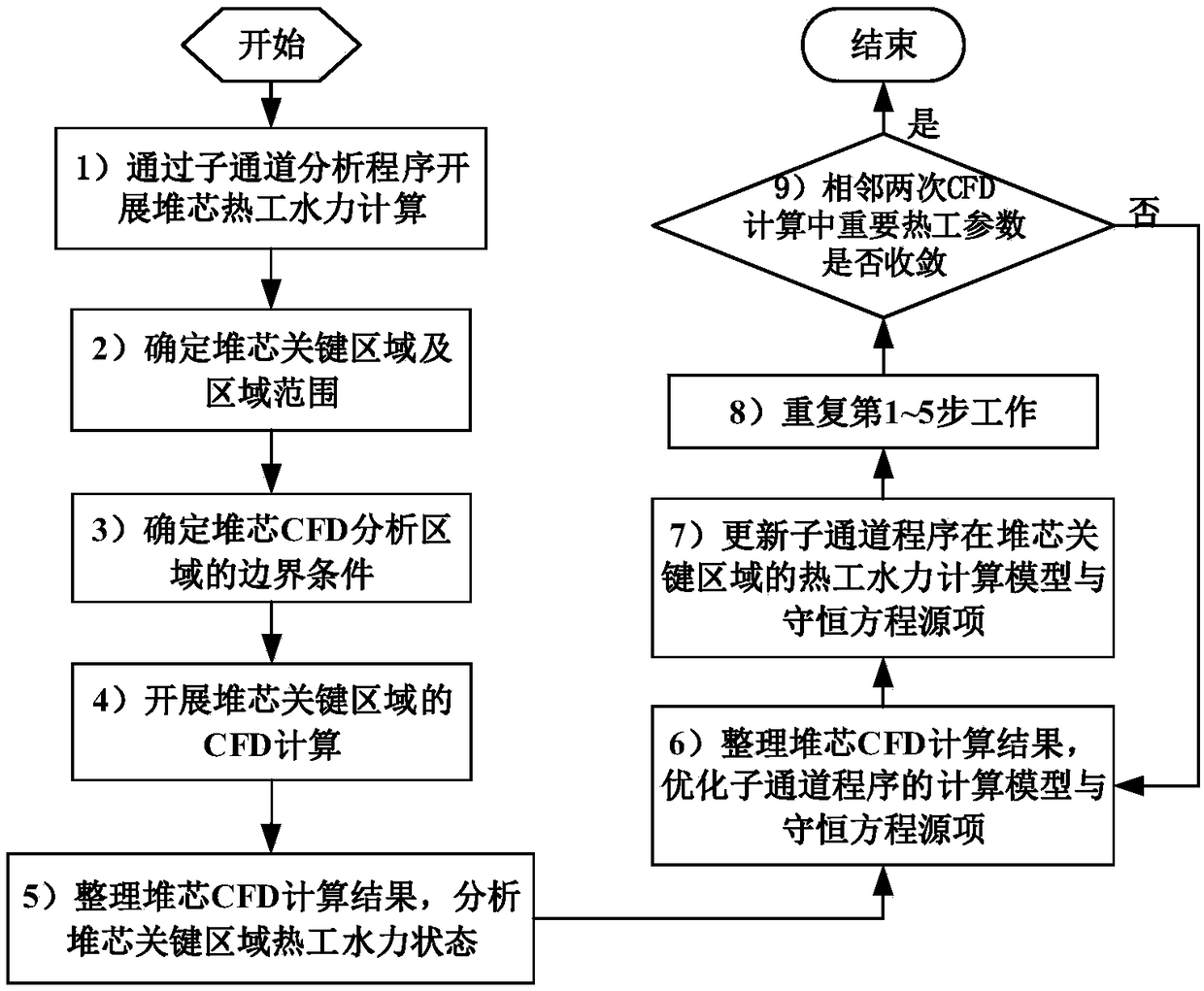

[0039] Step 1: Carry out core thermal-hydraulic calculations through the core subchannel analysis program.

[0040] Step 2: Determine the location and area range of the key area of the reactor core. Specific content: analyze the calculation results of the core thermal hydraulic sub-channel program, and screen the high-temperature sub-channel program control body and the number of control bodies for coolant, fuel cladding, and pellets , or the sub-channel control volumes and the number of control volumes corresponding to the large temperature gradient, large flow rate gradient, large pressure gradient and other parameter large gradient areas, and the actual geometric area of the core corresponding to all the selected control volumes is the core core area .

[0041] Step 3: Determine the boundary conditions of the core CFD analysis area, specific content: for the critical area of the core deter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com