Thermal hydraulic multi-scale partition simulation method of nuclear power device main-coolant system

A main coolant, thermal hydraulic technology, applied in design optimization/simulation, special data processing applications, instruments, etc., can solve problems such as large differences in calculation time costs, system flow calculation divergence, pressure calculation oscillations, etc., to achieve guaranteed Partial fine calculation, improve the calculation fineness, and ensure the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following examples describe the present invention in more detail.

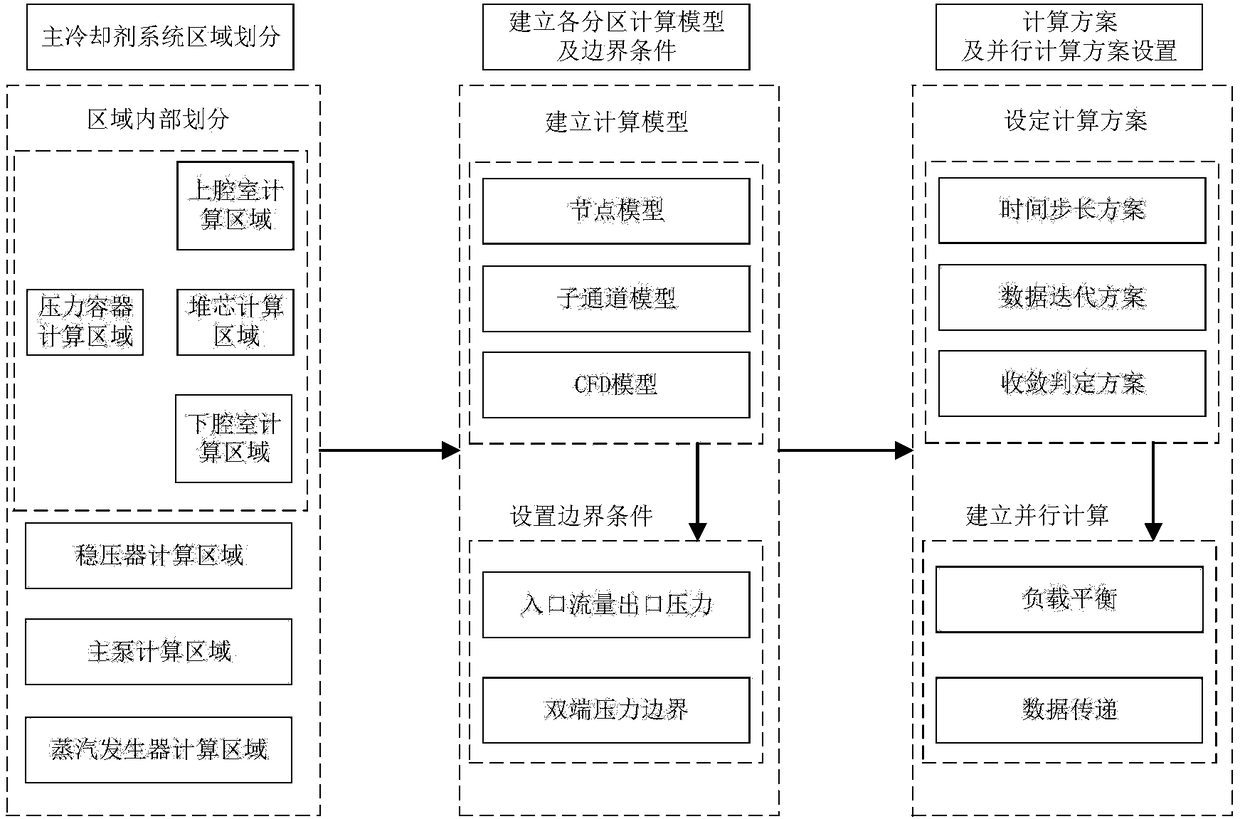

[0025] combine figure 2 , the implementation steps of the present invention are as follows:

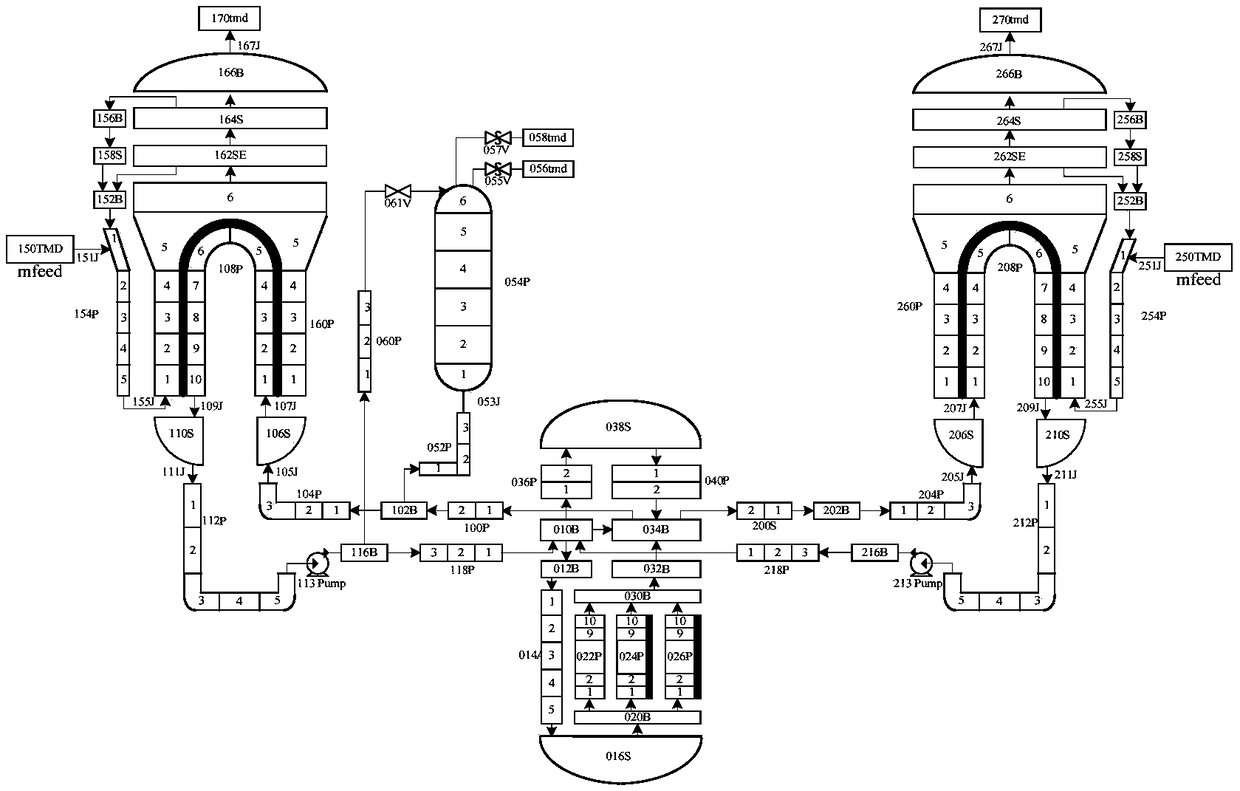

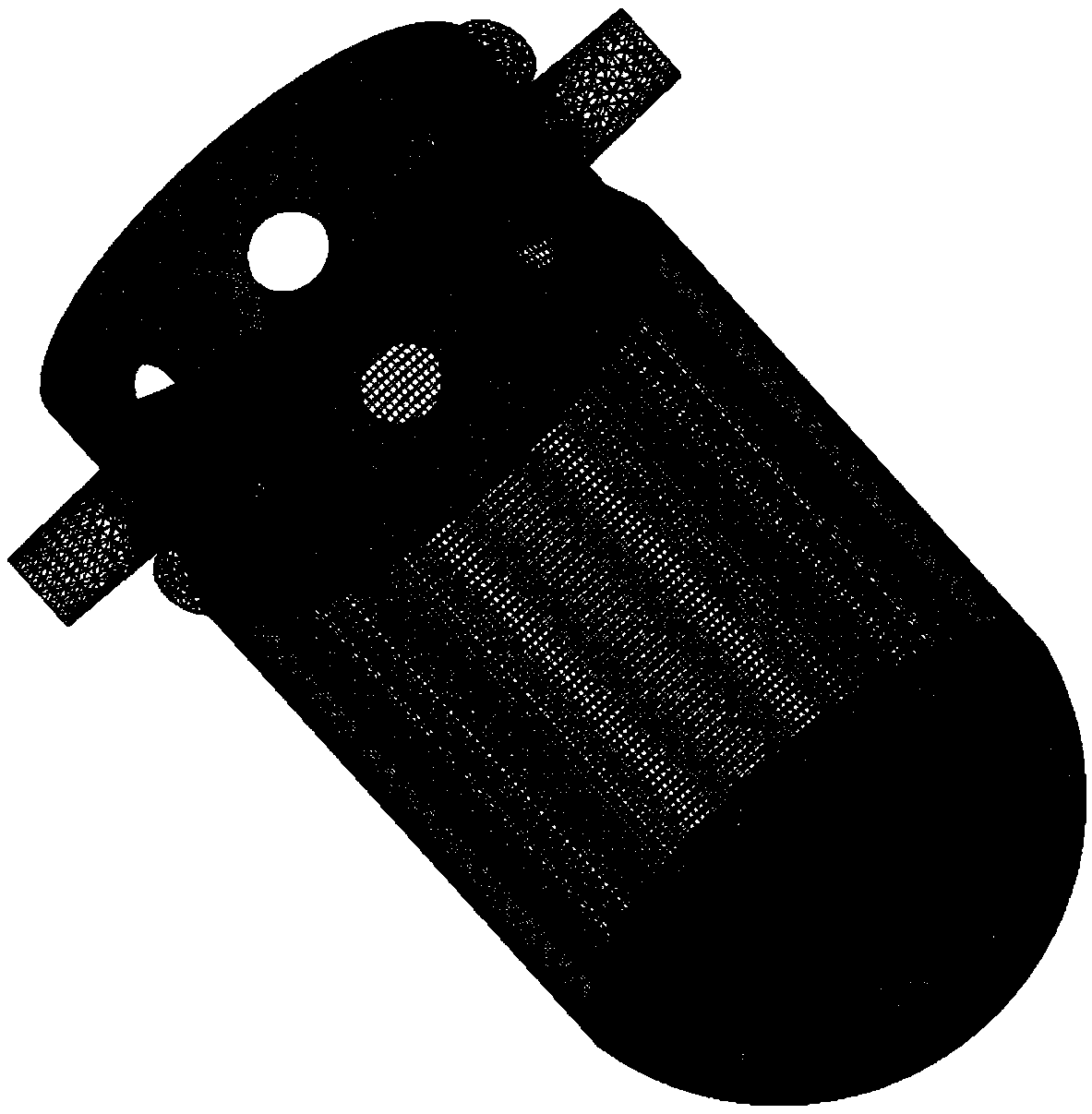

[0026] (1) According to the actual equipment in the system, the calculation area of the main coolant system is divided, including the core pressure vessel calculation area, the steam generator calculation area, the main pump area, the pressurizer area and the pipeline area between the equipment. The calculation area of the core pressure vessel includes the core upper chamber and outlet section area, the core fuel assembly area, the core inlet descent section and the core lower chamber area; the physical boundaries of each partition must coincide and correspond one by one. Specifically, it is implemented like this:

[0027] a. The calculation area of the core pressure vessel takes the pressure vessel inlet and outlet as the equipment boundary, the parameter transfer boundary is set between the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com