Electric vehicle deceleration and differential integrated rear axle assembly

A technology for electric vehicles and rear axles, applied in vehicle components, control devices, transportation and packaging, etc., can solve the problems of large friction loss of parts, large output power loss, and high vehicle repair rate, and achieve low output power loss. , Reduce the friction loss of transmission, the effect of smooth transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

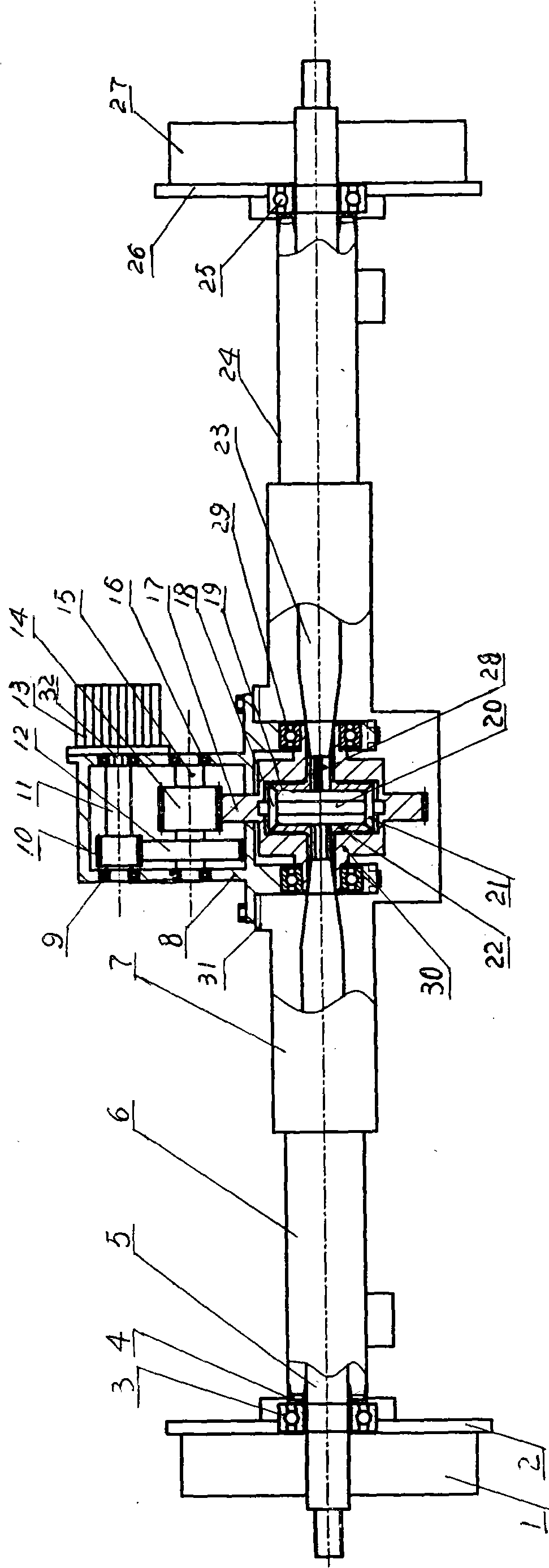

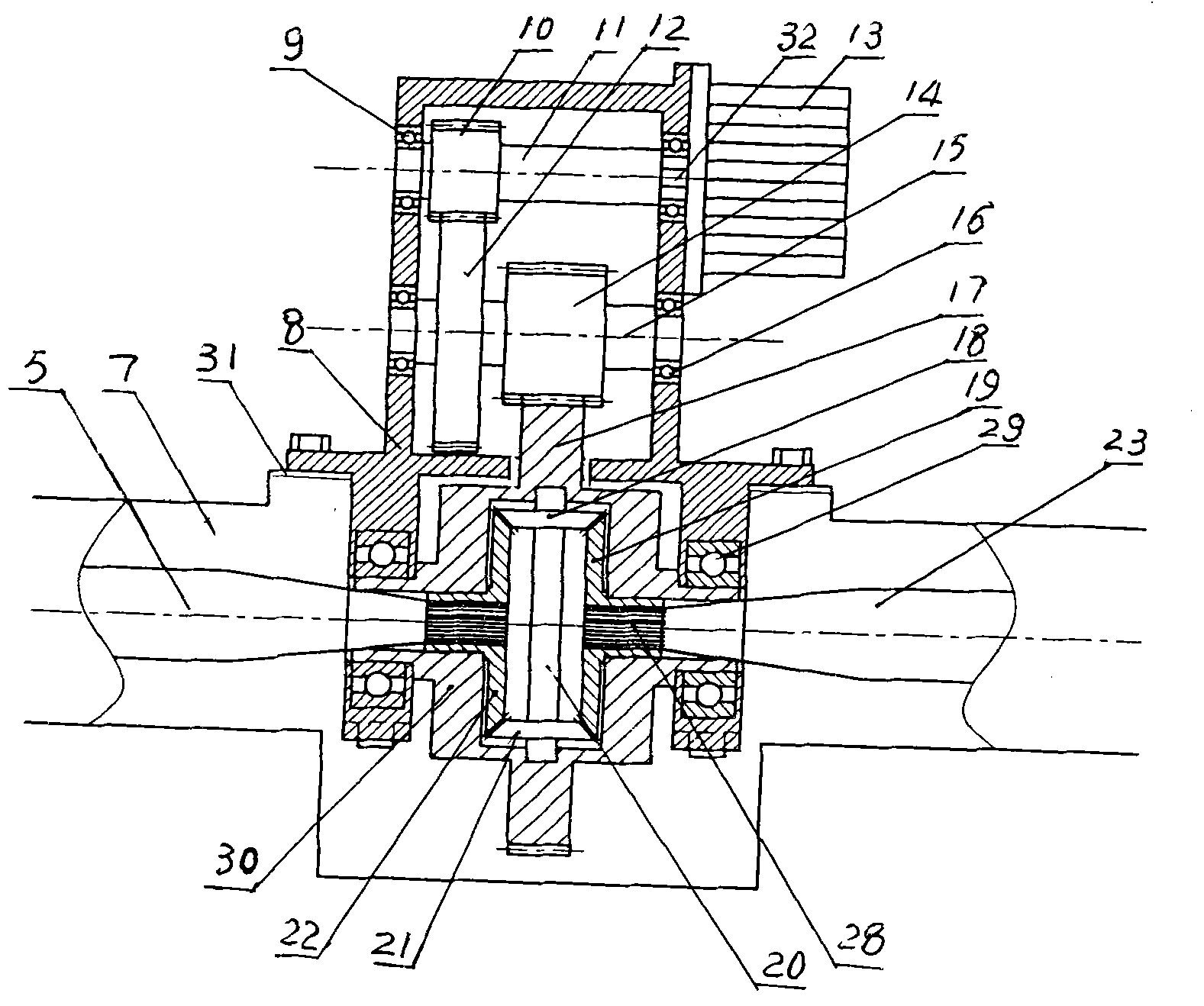

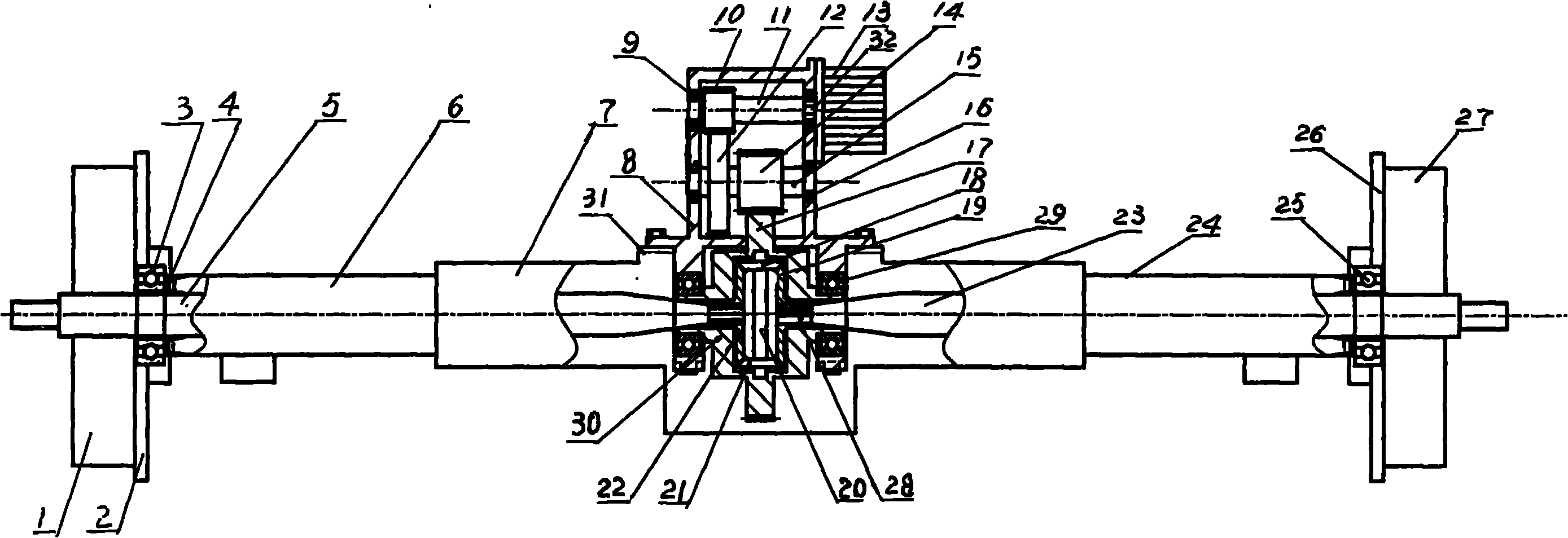

[0017] Refer to attached figure 1 , 2 , Electric vehicle deceleration, differential integrated rear axle assembly is made up of motor 13, speed reducer, differential, deceleration differential casing 8 and rear axle.

[0018] Rear axle comprises rear axle frame 7, axle shaft one 5, axle shaft two 23, brake fixing plate one 2, brake fixing plate two 26, brake block, brake cam, wheel hub one 1 and wheel hub two 27. Bridge tube one 6 and bridge tube two 24 are respectively arranged at rear bridge frame 7 both sides, and brake fixing plate one 2 is housed in bridge tube one 6 outsides, and brake fixing plate two 27 is housed in bridge tube two 24 outsides. Described brake fixed plate one 2 and brake fixed plate two 27 are equipped with two brake blocks, and two brake blocks are contained on the brake fixed plate by brake positioning pins, and brake projection is housed between two brake blocks. Half shaft one 5 and half shaft two 23 are provided with splines 28 at one end, half ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com