Method for mounting crawler cranes in side slope sites

A technology of a crawler crane and an installation method, applied in the direction of the crane, etc., to achieve the effects of smooth steering, small tonnage, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

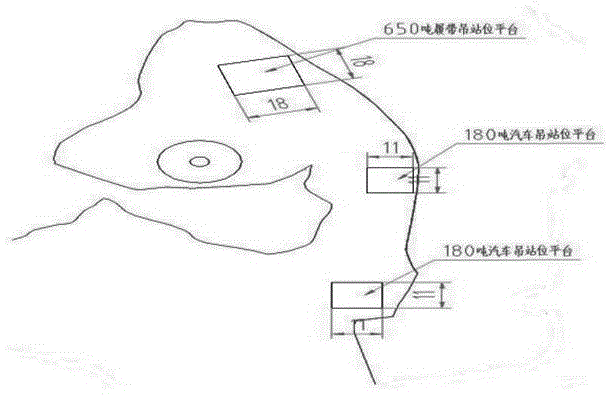

[0031] As shown in the figure, the construction environment in this embodiment is relatively complicated, and the height difference between the aircraft stand platform and the approach road (need to borrow the road) is 22m. The effective use area of the aircraft position is small, the effective use length is 40m, and the maximum effective use width is 30m. In such an environment, it is very difficult to install a 650t crawler crane.

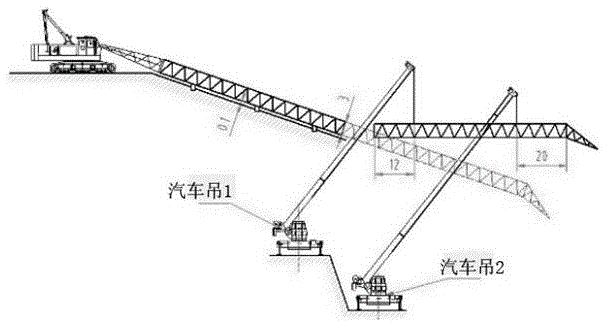

[0032] In this embodiment, the boom of the 650-ton crawler crane is divided into two sections for assembly, one section is the main boom, and the other end is the tower boom. Among them, the 48-meter main boom and the 7-meter wind power pole head weigh 37 tons in total. According to the site conditions, two truck cranes are used for hoisting, and the weight of the 48-meter main boom + 7-meter wind power pole head is shared equally by the two truck cranes, that is, each truck crane bears 37 / 2=18.5 tons, and the hoisting weight is carried out ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com