Manufacturing process for bearing plate of planetary carrier of automobile CVT automatic transmission

A technology of automatic transmission and manufacturing process, which is applied to transmission parts, belts/chains/gears, mechanical equipment, etc. It can solve the problems of low cutting production efficiency, large investment in gear shaping processing equipment, low production efficiency, etc., and achieve production The effect of high efficiency, saving raw materials and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

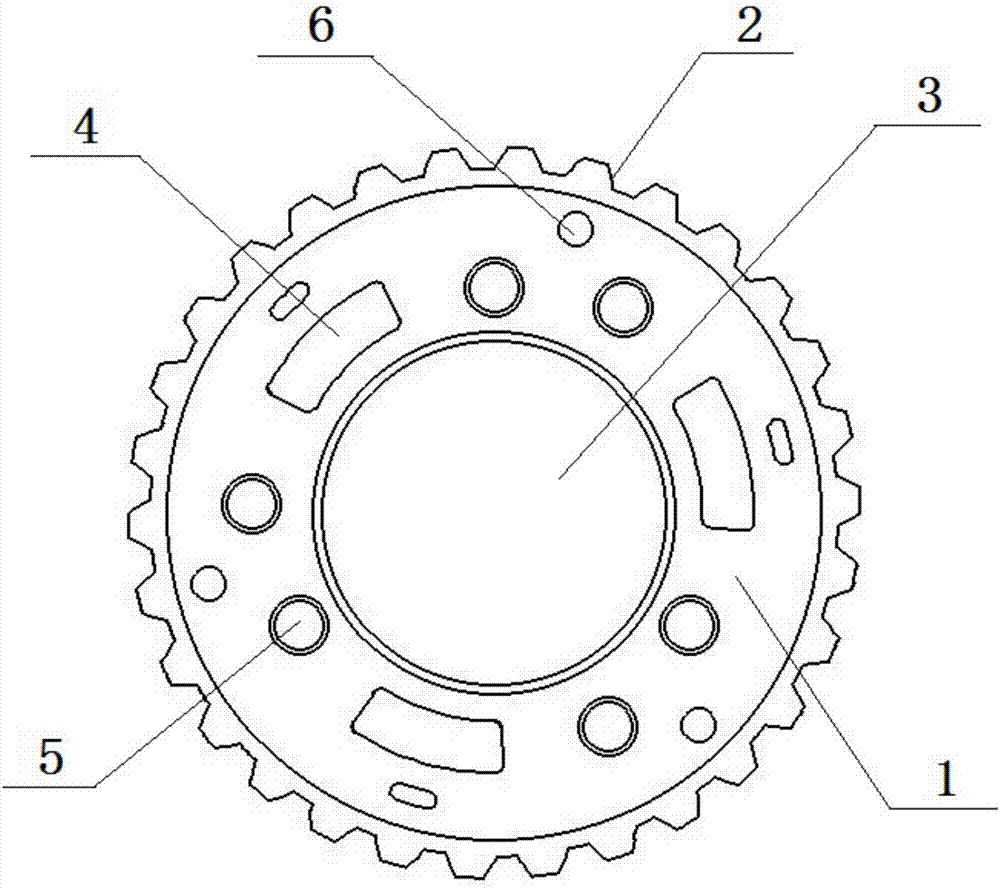

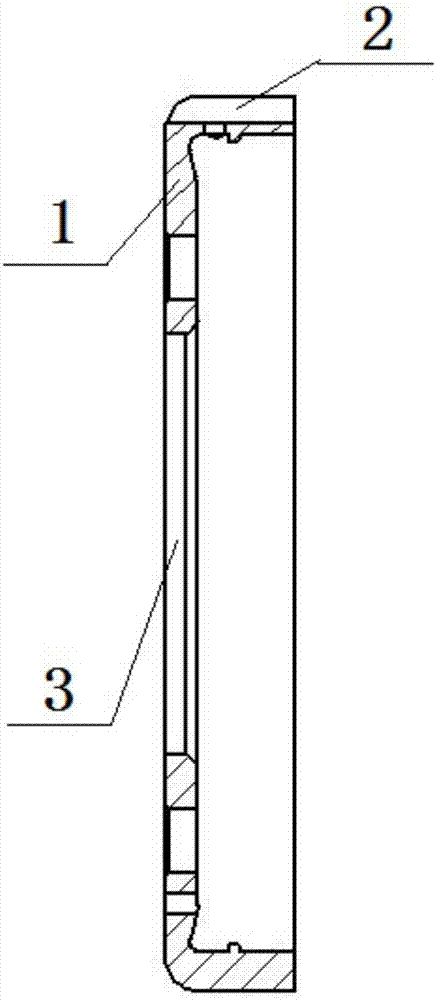

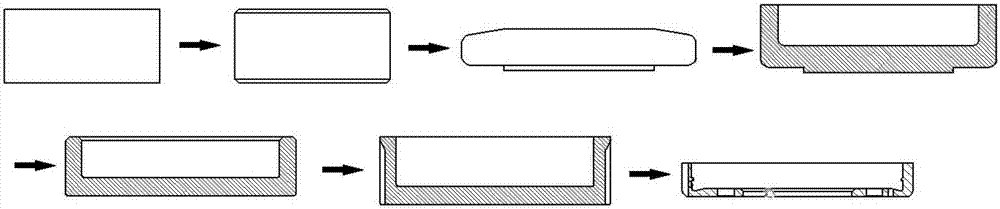

[0017] Example: see figure 1 As shown, a planetary carrier plate of an automotive CVT automatic transmission includes a circular plate 1 and an outer ring gear 2 extending vertically to one side at the peripheral edge of the circular plate. The circular plate 1 is provided with a central hole 3 and a planetary carrier bracket. Hole 4, gear hole 5 and positioning hole 6. see figure 2 As shown, the manufacturing process of the carrier plate of the planetary carrier of the automobile CVT automatic transmission includes the following steps: one is blanking: select 20# steel bar material, and cut the required length with a circular saw according to the size of the forging billet; the other is making it before warm forging Billet: lathe processing and peeling to remove surface defects of the billet; third shot blasting: place the billet in a crawler shot blasting machine for sand blasting to reduce the roughness Ra value of the outer surface of the billet, and provide conditions f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com