Sliding engagement sleeve of new energy automobile and manufacturing technique of sliding engagement sleeve

A technology of new energy vehicles and meshing sleeves, which is applied in the direction of mechanically driven clutches, mutually meshing clutches, clutches, etc., can solve the problems of difficulty in meeting the quality requirements of new energy vehicle parts, low cutting production efficiency, and insufficient tooth surface compactness. Good and other problems, to achieve the effect of improving material utilization, high production efficiency, and high mechanical properties of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

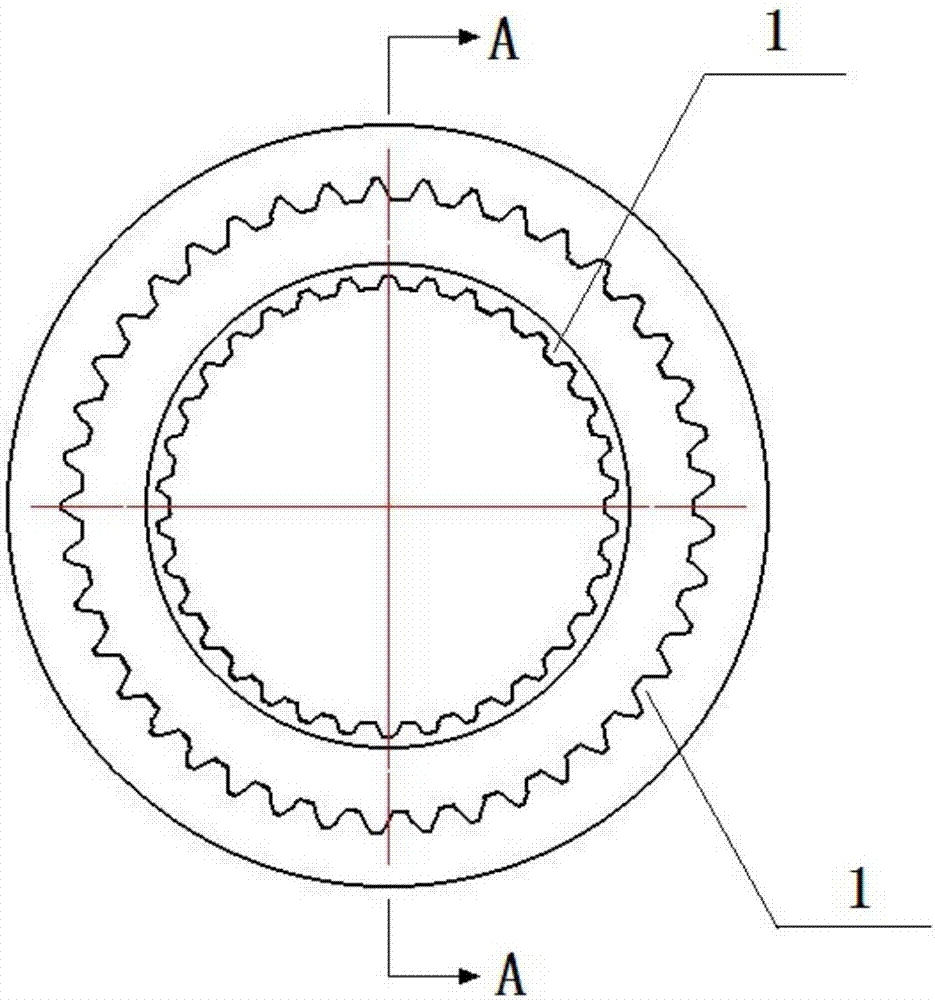

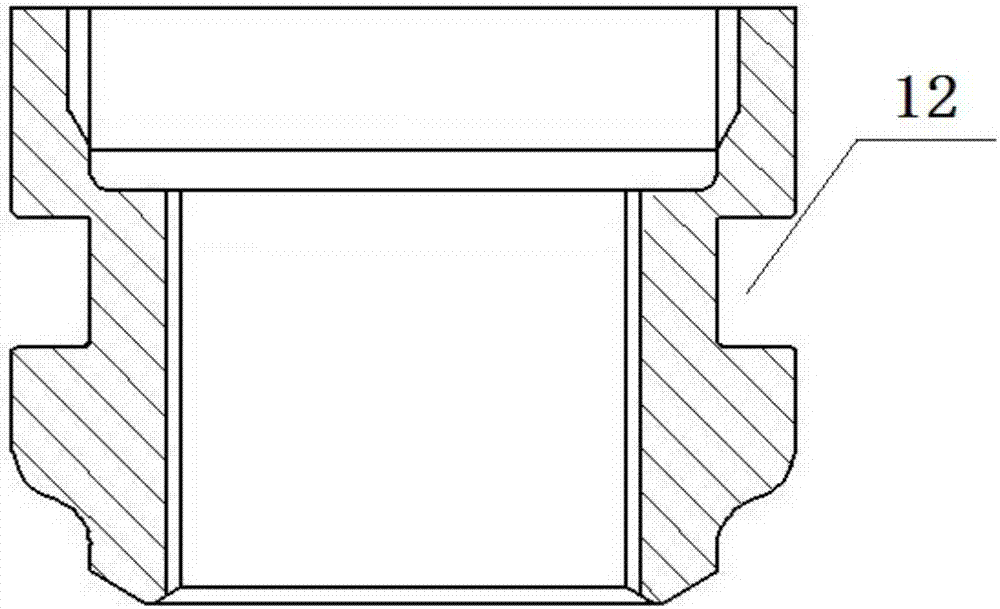

[0023] Example: see figure 1 and figure 2 As shown, a new energy vehicle sliding engagement sleeve, which is a hollow cylinder structure, the inner cavity is a structure of two cylinders with different sizes and inner diameters, and the inner wall is provided with meshing teeth 1; the outer wall corresponds to the end surface of the hollow cylinder with a small inner diameter. Shape, the outer wall is also provided with a circumferential groove 12.

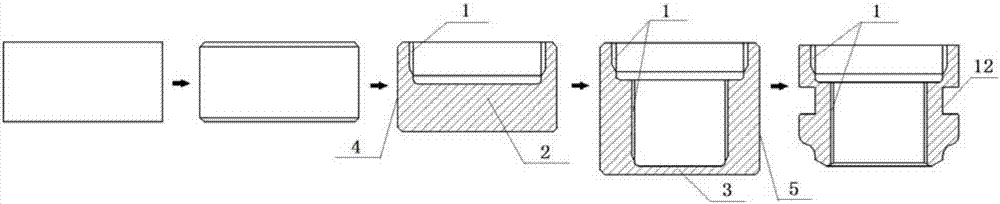

[0024] see image 3 and Figure 4 As shown, the manufacturing process of the sliding engagement sleeve for new energy vehicles includes the following steps: ①Blanking: the raw material is 20CrMnTiH, the diameter of the bar is selected, and the metal bar is cut with a circular saw; ②Spheroidizing annealing: the bar is loaded into the furnace Heating to 720°C-780°C for spheroidizing annealing, spheroidizing rate ≥ 90%, hardness ≤ 80HRC; ③ Billet making: peeling to remove surface oxide and chamfering; ④ Shot blasting: send the bi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com