Temperature cooling precision forming method of big modulus high boss bevel gear

A technology of precision forming and high boss, which is used in manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machines, etc., can solve the problems of high material cost, complicated procedures, poor mechanical properties, etc. Simple structure, low cost, and the effect of mold life guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] A method for warm and cold precision forming of a large modulus high boss bevel gear, comprising the following steps:

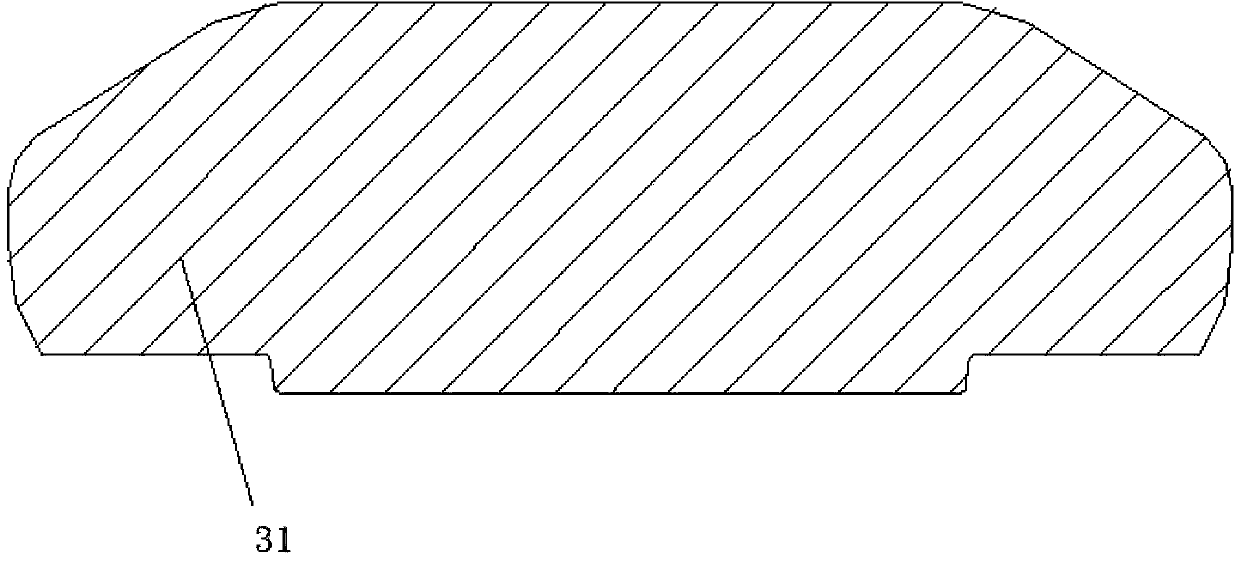

[0031] (1) Use a cylindrical bar sawing machine to cut the blank, and heat the blank to 750°C through an intermediate frequency diathermy furnace, and then refer to figure 1 The structural pre-heading blank 31;

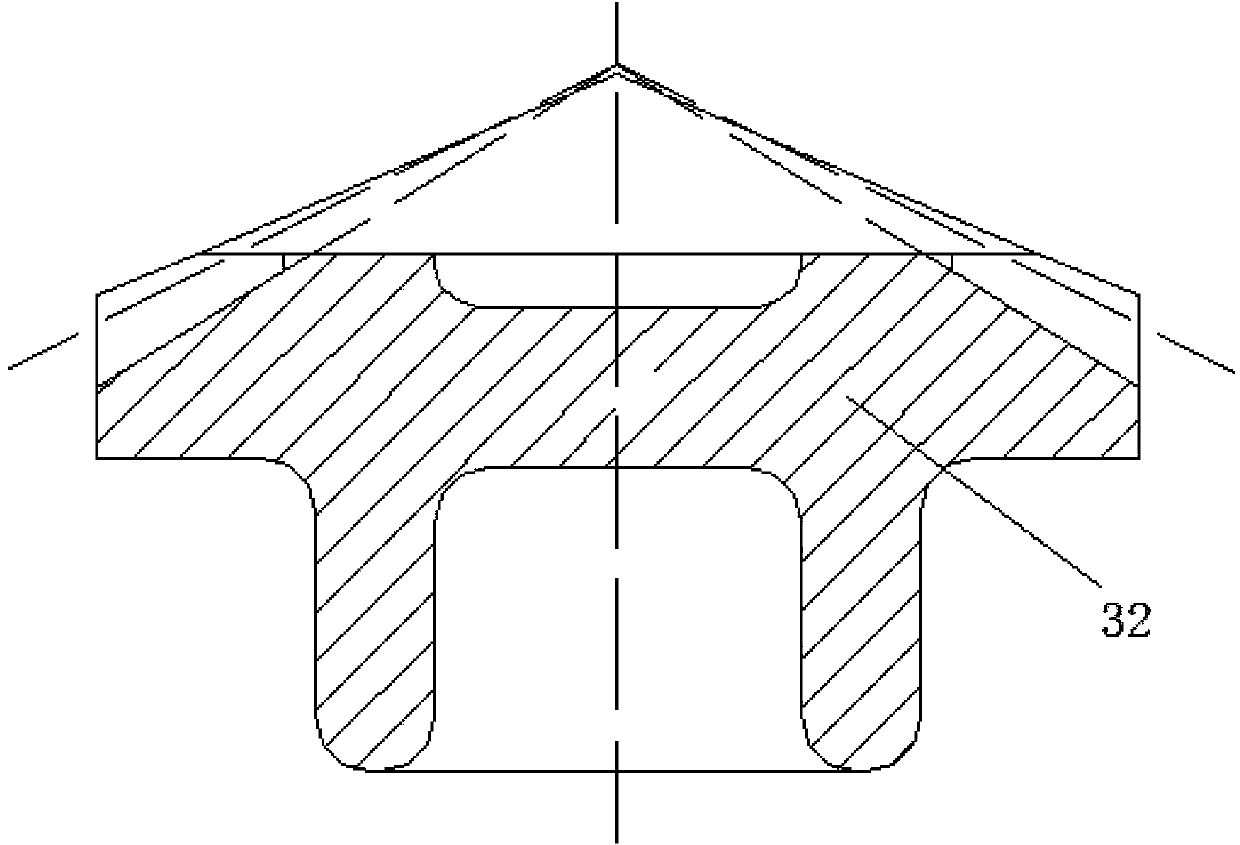

[0032] (2) Quickly put the pre-forged forging on one side of the warm forging closed forming mold for warm forging closed forming; this process needs to grasp the speed beat and minimize the influence of temperature drop on the process, so pre-forging should be considered The placement between the equipment and the warm forging equipment, install the pre-forging equipment and the warm forging equipment back to back, reduce the running distance of the workpiece from the pre-forging equipment to the warm forging equipment, and reduce the temperature drop;

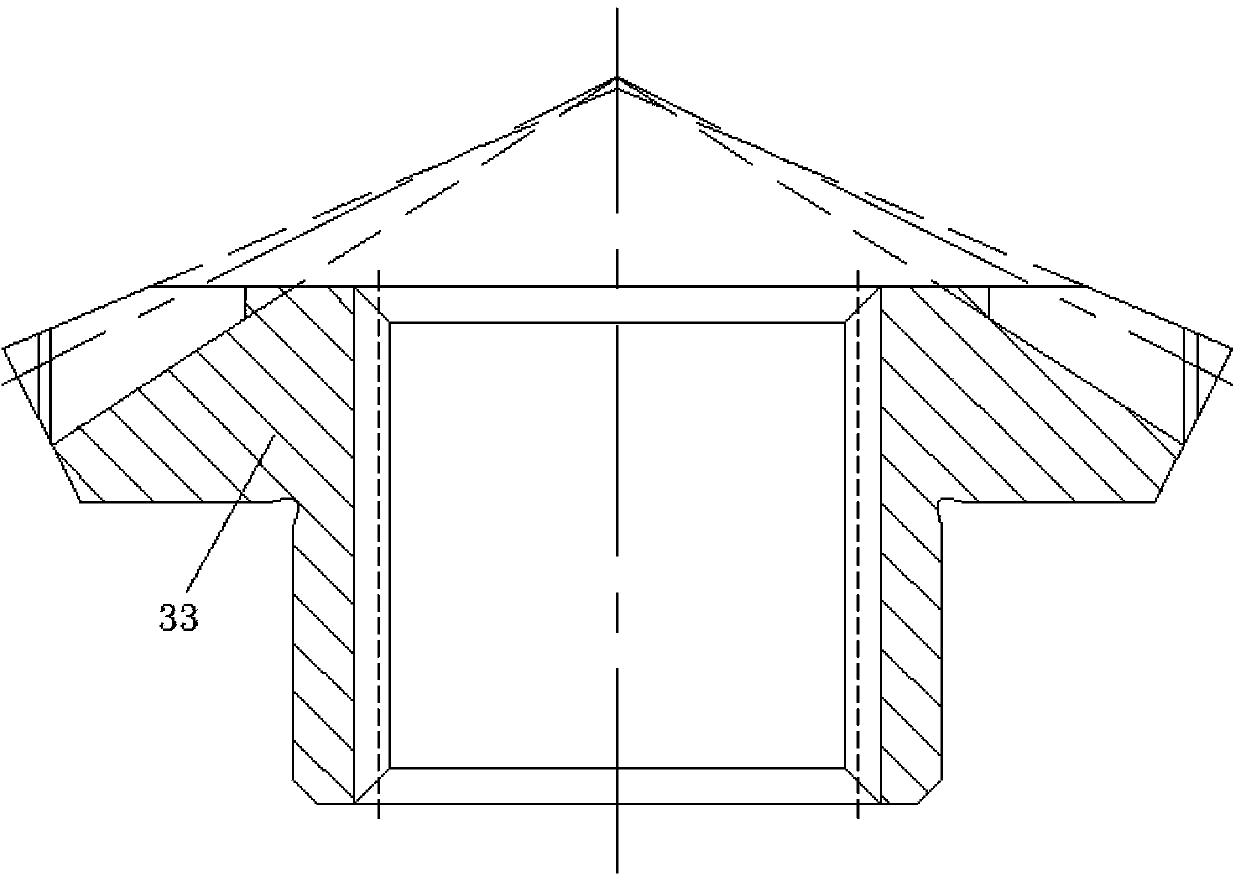

[0033] (3) Spheroidizing and annealing the warm forged and closed parts to reduce their ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com