Special chain drive pumping unit

A pumping unit, a special technology, applied in the direction of belt/chain/gear, mechanical equipment, mining fluid, etc., can solve the problems of increasing the wear of the guide wheel and the guide rail of the frame, labor and time, and accelerated wear, so as to reduce the power of the motor , reduce the cost of use, reduce the effect of wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

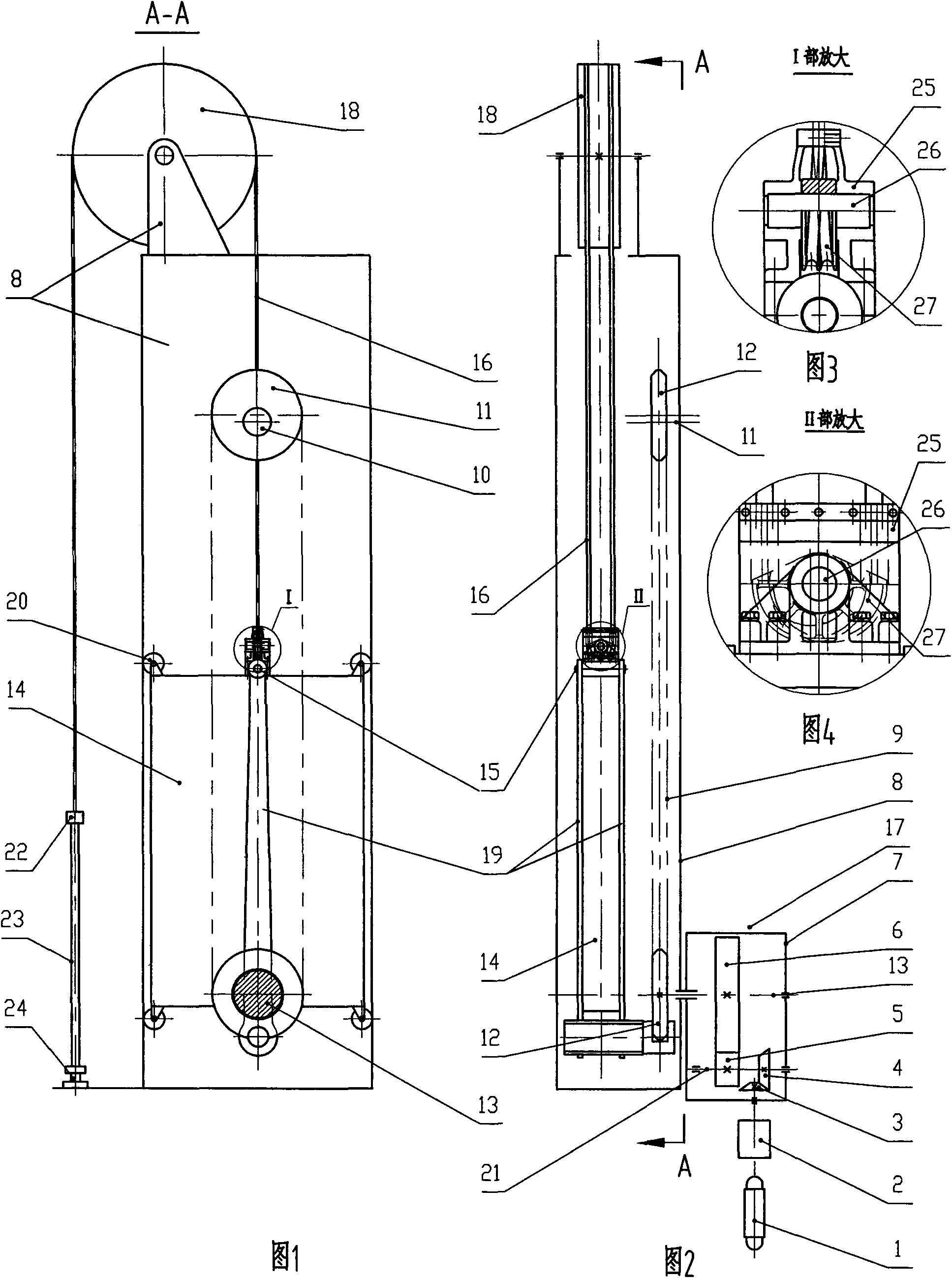

[0039] The present invention will be described in detail below using the drawings and embodiments.

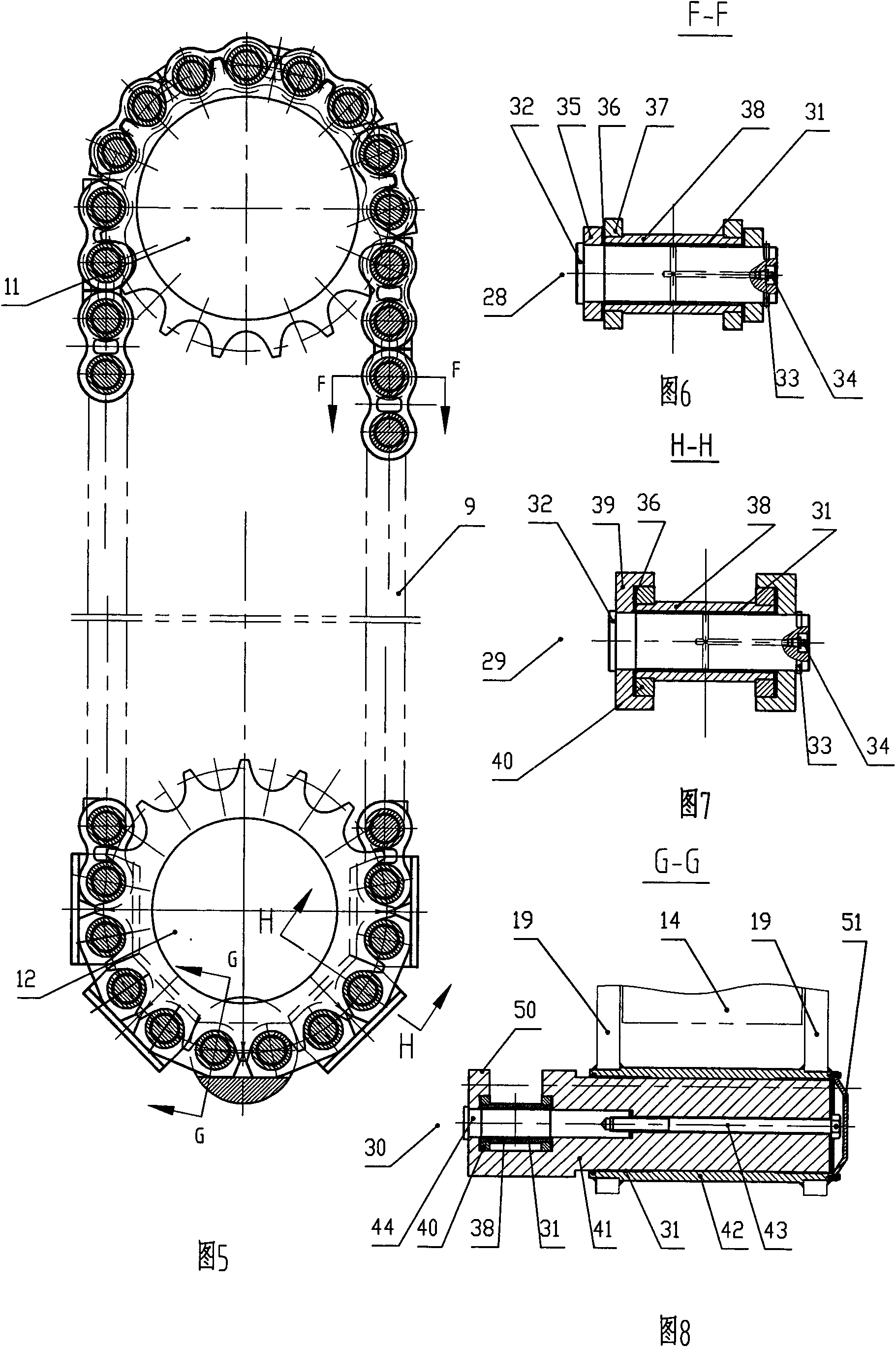

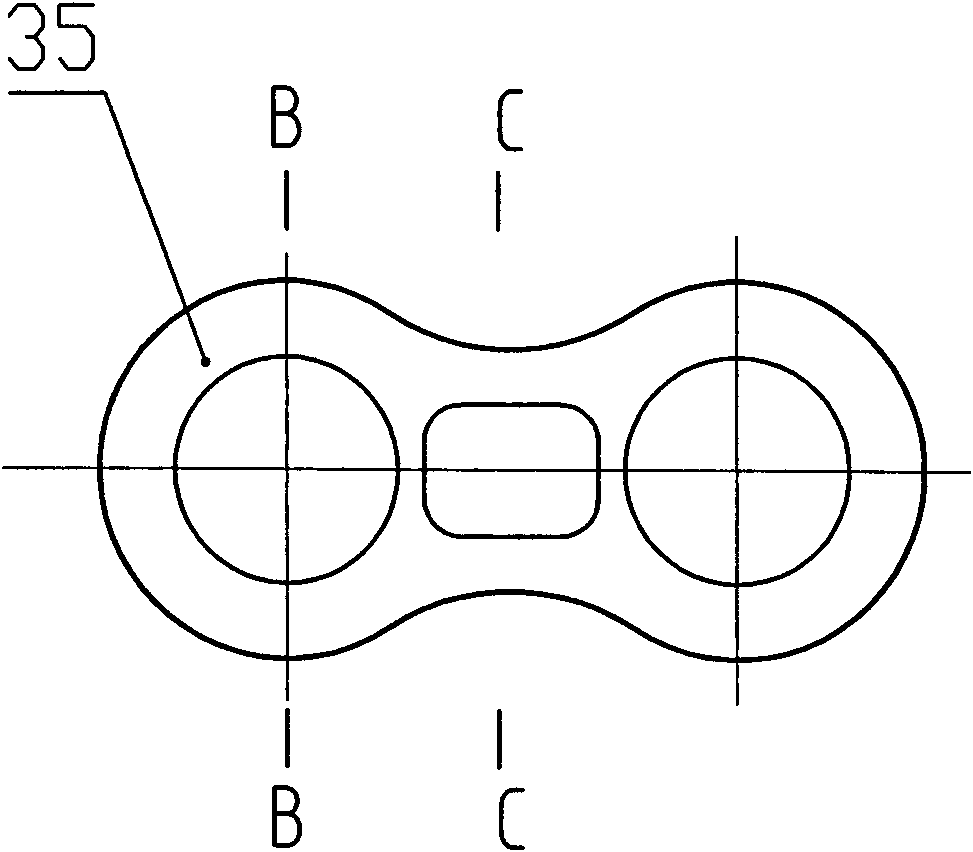

[0040] refer to Figure 1-4 , the special chain pumping unit of the present invention has frame 8, is built-in balance box 14 in frame 8, and balance box 14 contacts with the guide rail built in frame 8 by the guide wheel 20 that is hinged on it. A driven sprocket 11 is fixedly connected on the driven sprocket shaft 10 articulated by the frame 8, and a driving sprocket 12 is fixedly connected on the power output shaft 13 articulated by the frame 8. The driven sprocket 11 and the driving sprocket 12 Surround special chain9. One end of the connecting rod 19 placed on both sides of the balance box 14 is fixedly connected to the shaft seat 42 of the special chain link 30 of the special chain suspension load, and the other end of the connecting rod 19 is connected to the traction rope hanger 25 and the balance through the connecting pin shaft 15 Case 14 is hinged, and traction rope ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com