Chain and chain wheel

A chain and special technology, applied in the direction of belt/chain/gear, chain ring, transmission chain, etc., can solve the problems of reducing the service life of chain pumping units, increasing maintenance time, affecting the efficiency of pumping operations, etc., and reaching the service life The effect of long length, high tooth surface strength and stable transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below using the drawings and embodiments.

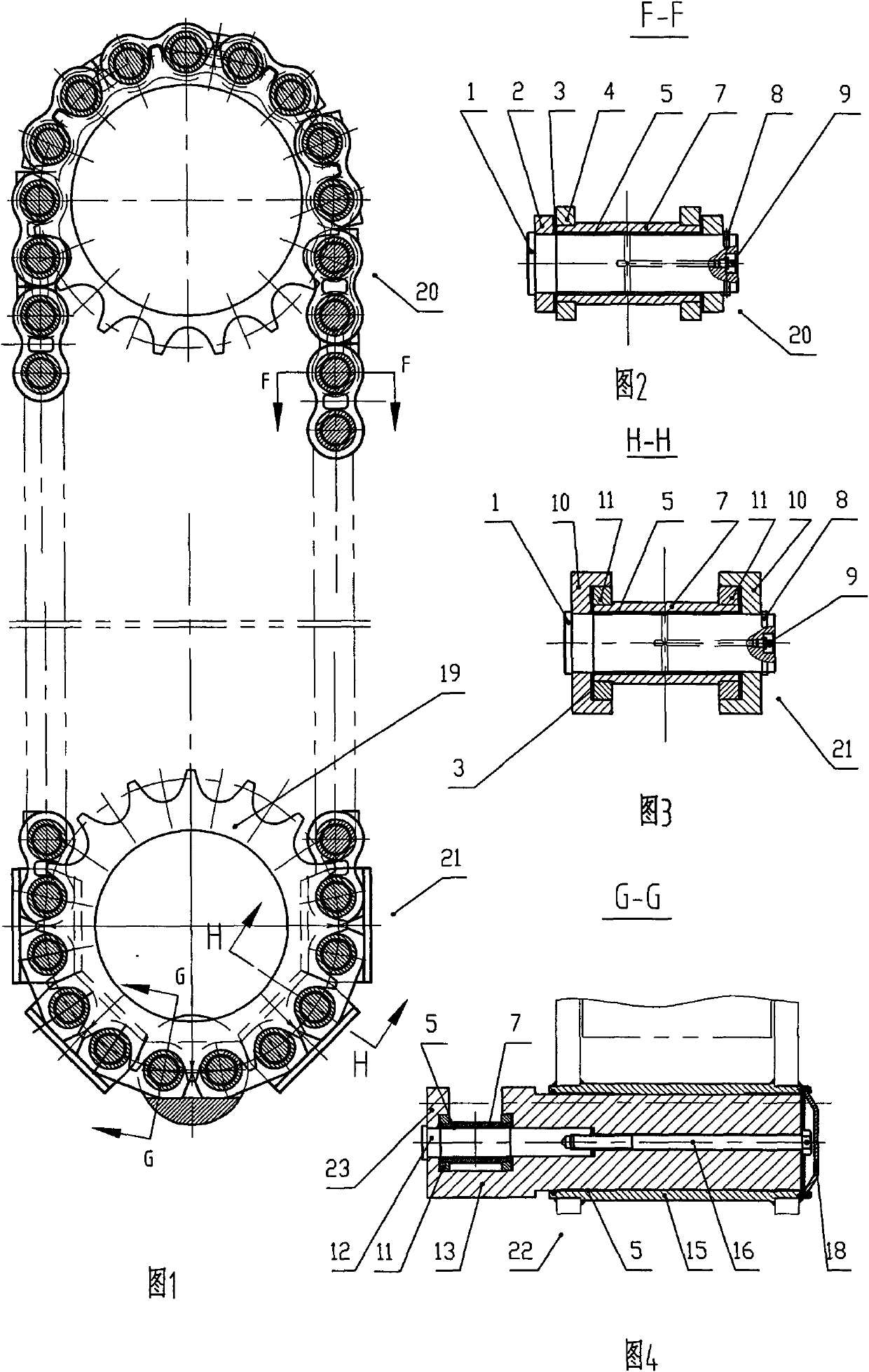

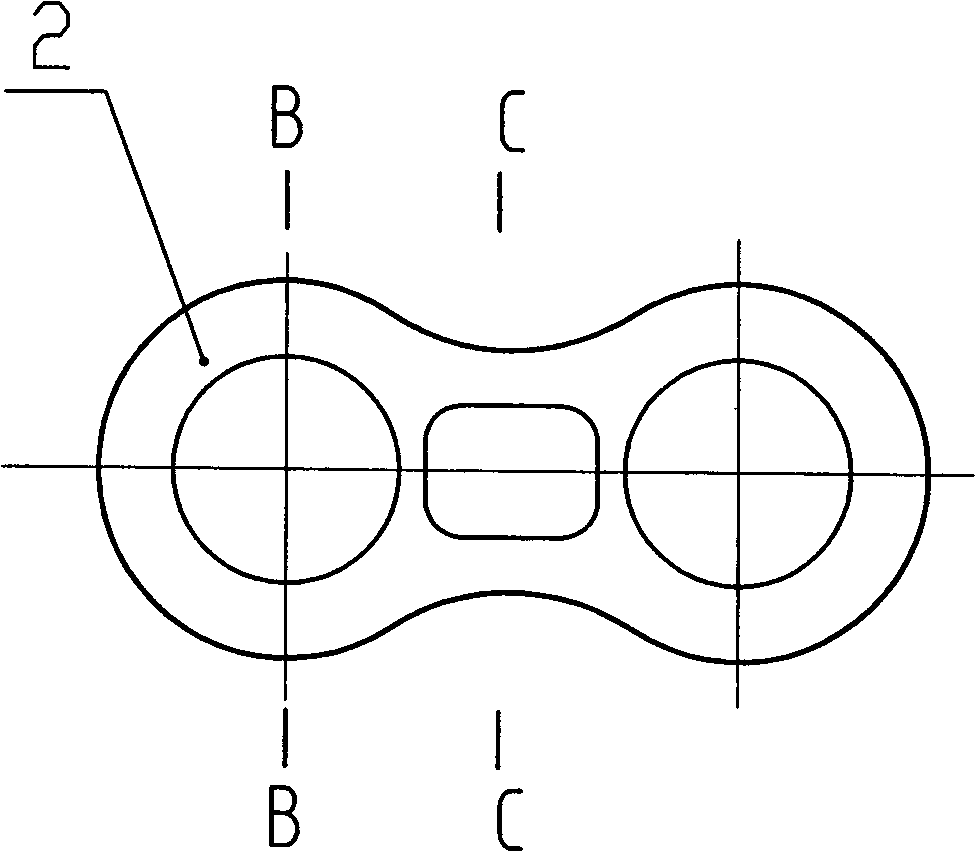

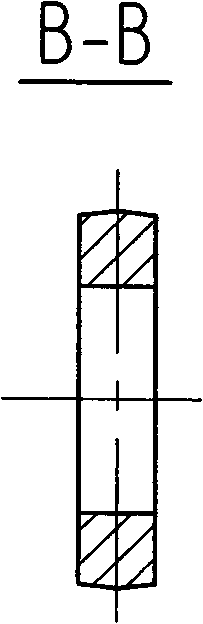

[0032] refer to figure 1 , 2 And 5-10, a chain includes several joints 20 hinged in turn, several joints 20 are existing common chains, the structure of the chains 20 is to include rollers 7, and the two ends of the rollers 7 are nested Chain plate 4, sealing ring 3 is placed on the outside of inner chain plate 4 to contact with outer chain plate 2, and is hinged by pin 1, and the shaft end of pin 1 is fixed with steel wire lock ring 8 for shaft. A composite bearing 5 is provided between the roller 7 of the chain link 20 and the pin shaft 1 . The composite bearing 5 of this embodiment adopts a three-layer composite bearing (GB293-82, Φ65×60×70). An oil cup 9 is fixedly connected to the shaft end of the bearing pin 1 . The oil cup 9 can inject lubricating oil into the composite bearing 5 .

[0033] refer to figure 1 , 3 , 4 and 11-14, several joint chain links 20 and so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com