Anti-impact structure of variable vane pump

A vane pump and anti-shock technology, which is applied to pumps, pump components, rotary piston pumps, etc., can solve the problems of low volumetric efficiency and flow reduction, achieve high volumetric efficiency, reduce tool wear, and eliminate system pressure. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

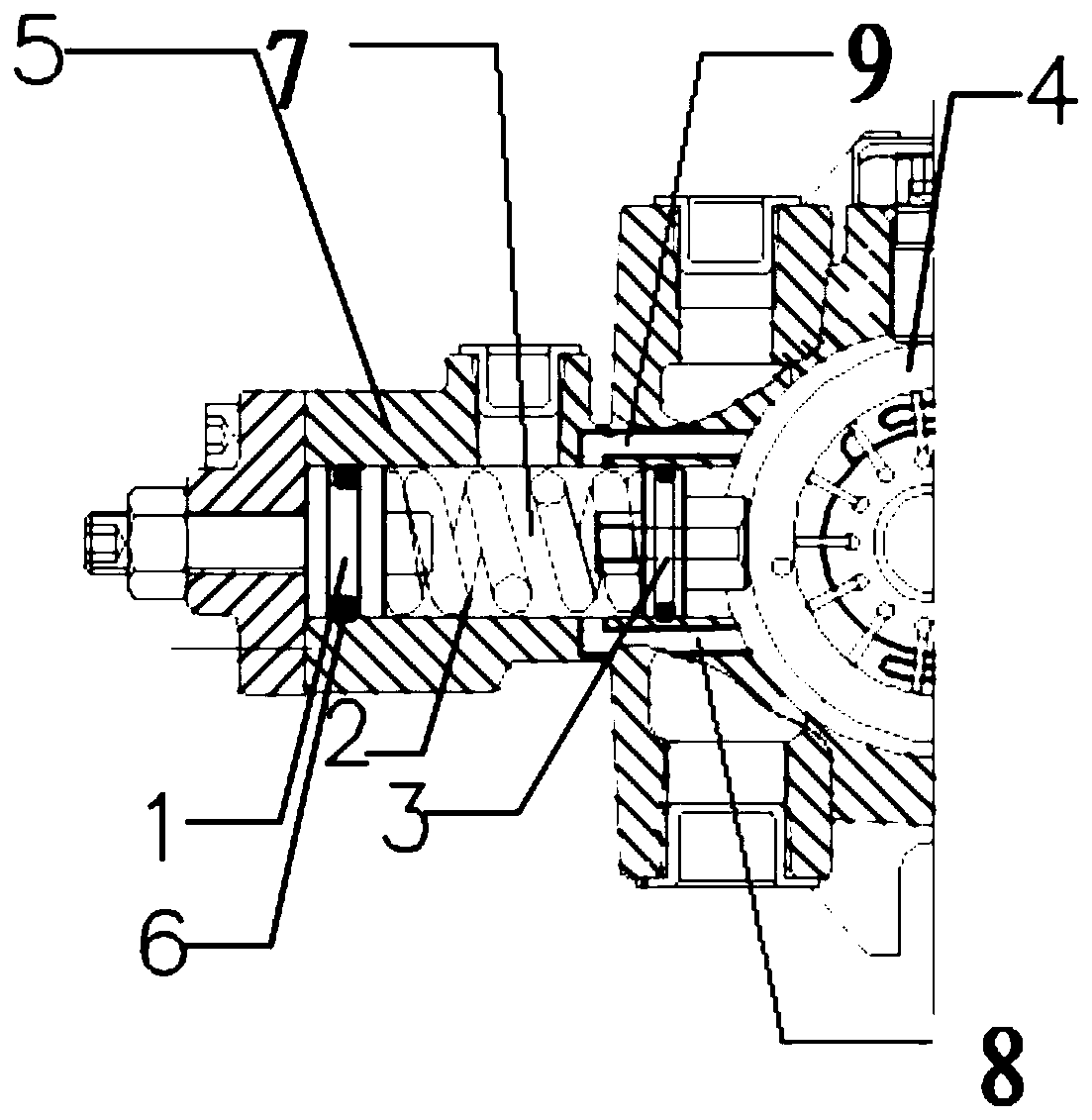

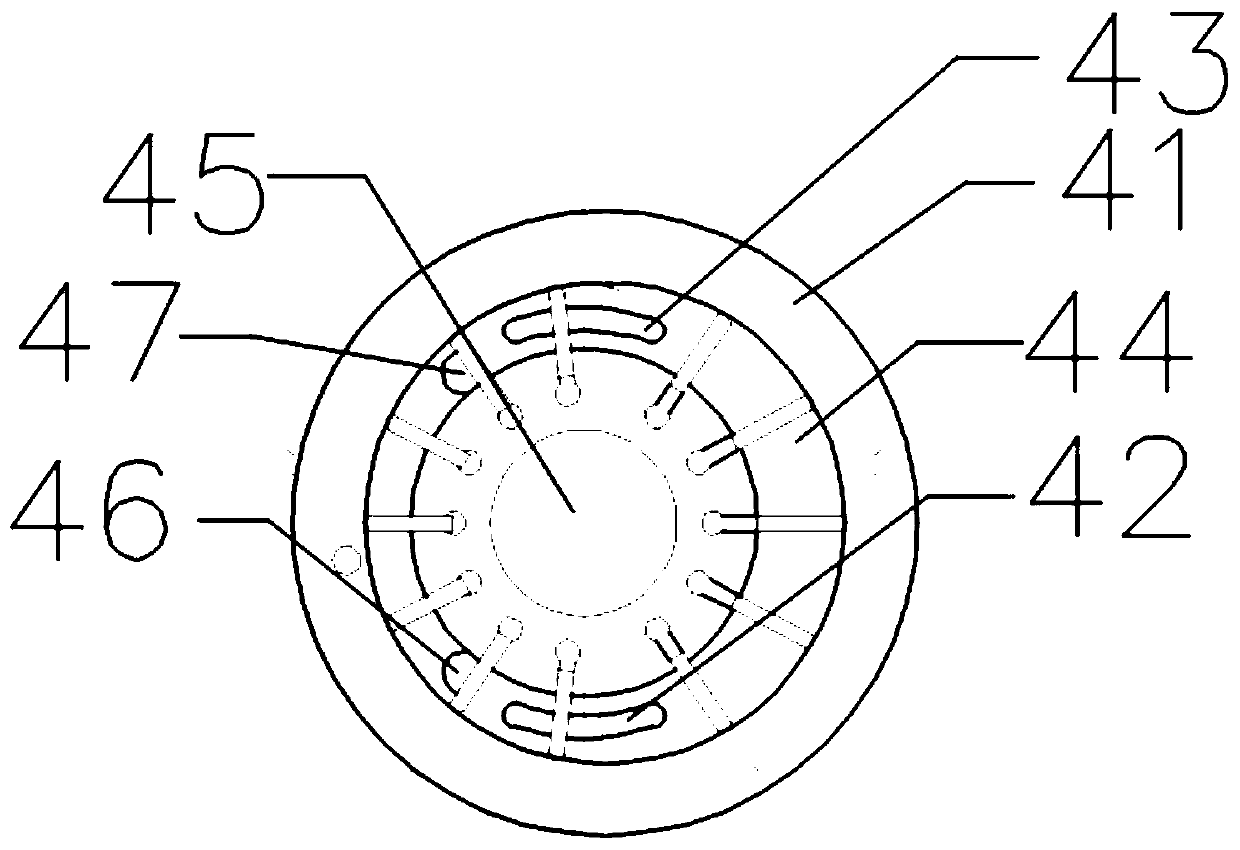

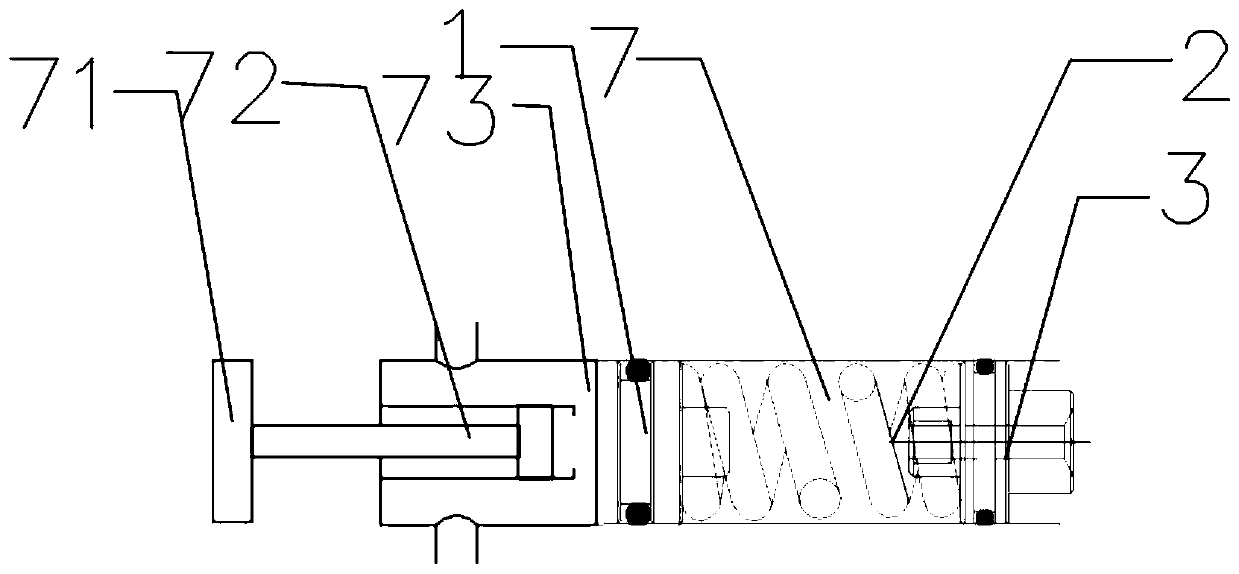

[0032] An anti-shock structure of a variable vane pump, including a pre-stretching member seat 1, a pre-stretching member 2, a top plug 3, a stator 4 and a pump body 5; one side of the pump body 5 is provided with a pressure adjustment hole 7, and a pressure adjustment hole 7 horizontal setting.

[0033] The position of the pressure adjustment hole 7 is provided with a pretensioner seat 1, the top plug 3 is arranged at the radial side end of the stator 4, and the pretensioner 2 is arranged inside the pressure adjustment hole 7 and connected to the pretensioner seat 1 and the top. The plug 3 and the stator 4 are arranged inside the pump body 5, radial grooves are arranged on the side surfaces of the pre-stretching member seat 1 and the top plug 3, and buffer structures 6 are respectively arranged inside the radial grooves, and the buffer structures are made of rubber material. The type ring, the O type ring fits the side wall of the pressure adjustment hole 7. The pre-stretchi...

Embodiment 2

[0037] An anti-shock structure of a variable vane pump, including a pre-stretching member seat 1, a pre-stretching member 2, a top plug 3, a stator 4 and a pump body 5; one side of the pump body 5 is provided with a pressure adjustment hole 7, and a pressure adjustment hole 7 horizontal setting.

[0038] The position of the pressure adjustment hole 7 is provided with a pretensioner seat 1, the top plug 3 is arranged at the radial side end of the stator 4, and the pretensioner 2 is arranged inside the pressure adjustment hole 7 and connected to the pretensioner seat 1 and the top. The plug 3 and the stator 4 are set inside the pump body 5, the side surfaces of the pre-tensioning member seat 1 and the top plug 3 are provided with radial grooves, and the inside of the radial grooves are respectively provided with a buffer structure, the buffer structure is an O-shaped rubber material The O-ring fits the side wall of the pressure adjustment hole 7. The pre-stretching piece seat 1...

Embodiment 3

[0043] An anti-shock structure of a variable vane pump, including a pre-stretching member seat 1, a pre-stretching member 2, a top plug 3, a stator 4 and a pump body 5; one side of the pump body 5 is provided with a pressure adjustment hole 7, and a pressure adjustment hole 7 horizontal setting.

[0044] The position of the pressure adjustment hole 7 is provided with a pretensioner seat 1, the top plug 3 is arranged at the radial side end of the stator 4, and the pretensioner 2 is arranged inside the pressure adjustment hole 7 and connected to the pretensioner seat 1 and the top. The plug 3 and the stator 4 are set inside the pump body 5, the side surfaces of the pre-tensioning member seat 1 and the top plug 3 are provided with radial grooves, and the inside of the radial grooves are respectively provided with a buffer structure, the buffer structure is an O-shaped rubber material The O-ring fits the side wall of the pressure adjustment hole 7. The pre-stretching piece seat 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com