Hydraulic damping force adjusting mechanism for hydraulic hinge

A technology of hydraulic damping and force adjustment, applied in the hinge field, can solve the problems of inconvenient installation and use, high manufacturing cost, sound, etc., and achieve the effect of simple structure and convenient manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing.

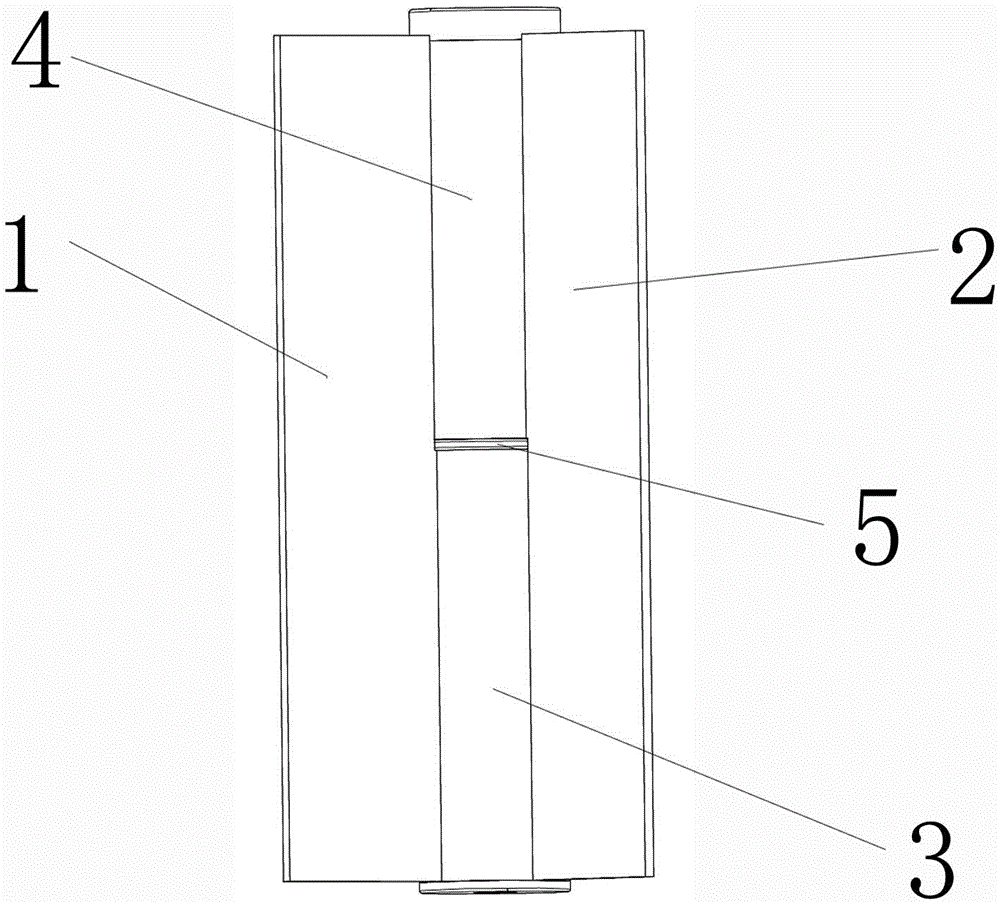

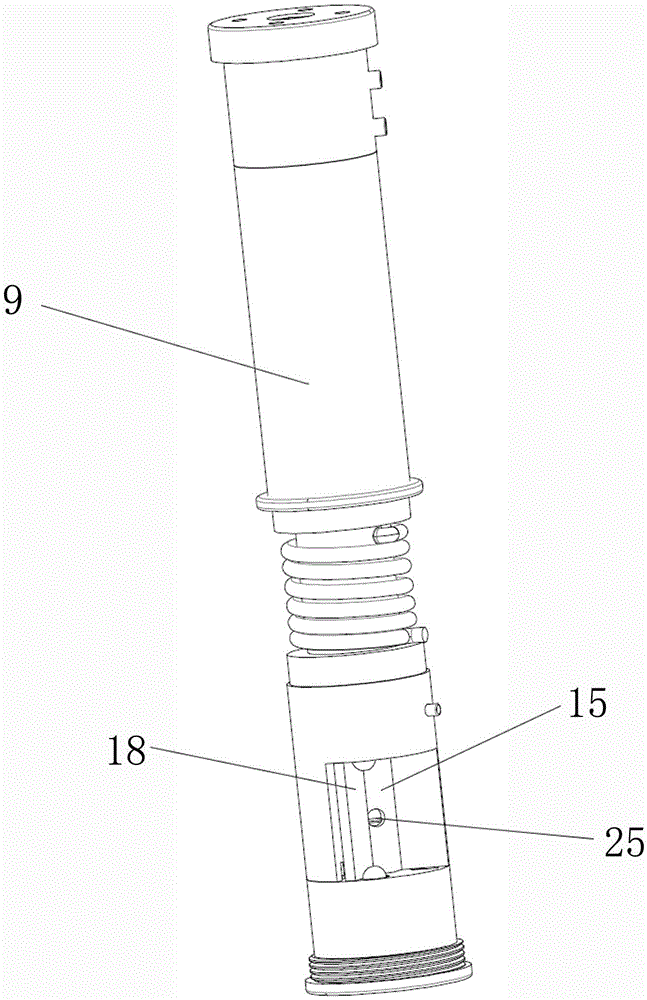

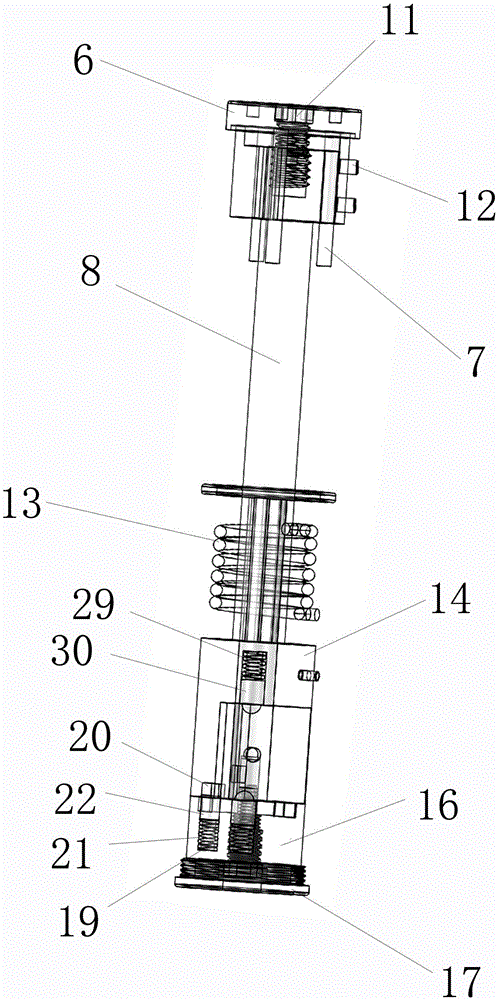

[0017] Such as Figure 1-7 As shown, the hydraulic hinge of the present invention includes a door frame fixed hinge 1 and a rotating hinge 2, the door frame fixed hinge 1 is fixed on the door frame, the rotating hinge 2 is fixed on the door, the door frame fixed hinge 1 and the rotating hinge 2 respectively have a lower storage bucket 3 and an upper storage bucket 4, the upper storage bucket 4 and the lower storage bucket 3 are separated by a plane bearing 5, the top of the upper storage bucket 4 is sealed by an upper end cover 6, and the upper end cover 6 has a plurality of columns 7. There is a mandrel 8 and a coupling sleeve 9 inside the upper containing barrel 4. There are a plurality of arc-shaped holes 10 on the mandrel 8. The upright column 7 passes through the arc-shaped holes 10. The upper end cover 6 and the mandrel 8 are connected by a first adjustment The fast ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com