Bearing for ultralow-temperature liquid pump

A liquid pump and ultra-low temperature technology, which is applied in the field of liquid pump bearings, can solve the problems of unsatisfactory bearing work and long-term work of the bearing, and achieve the effects of low friction loss, no loss of precision, and extended bearing life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

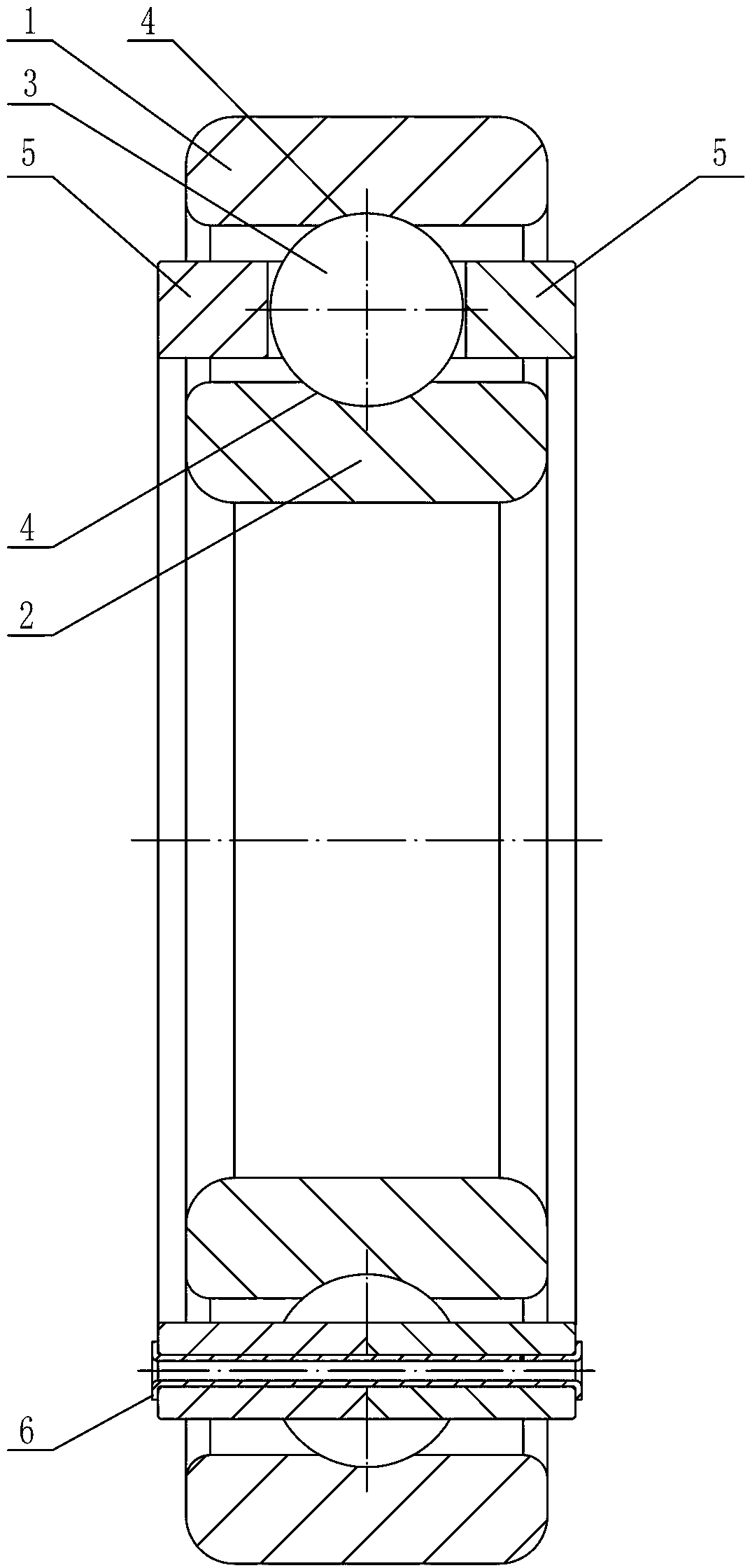

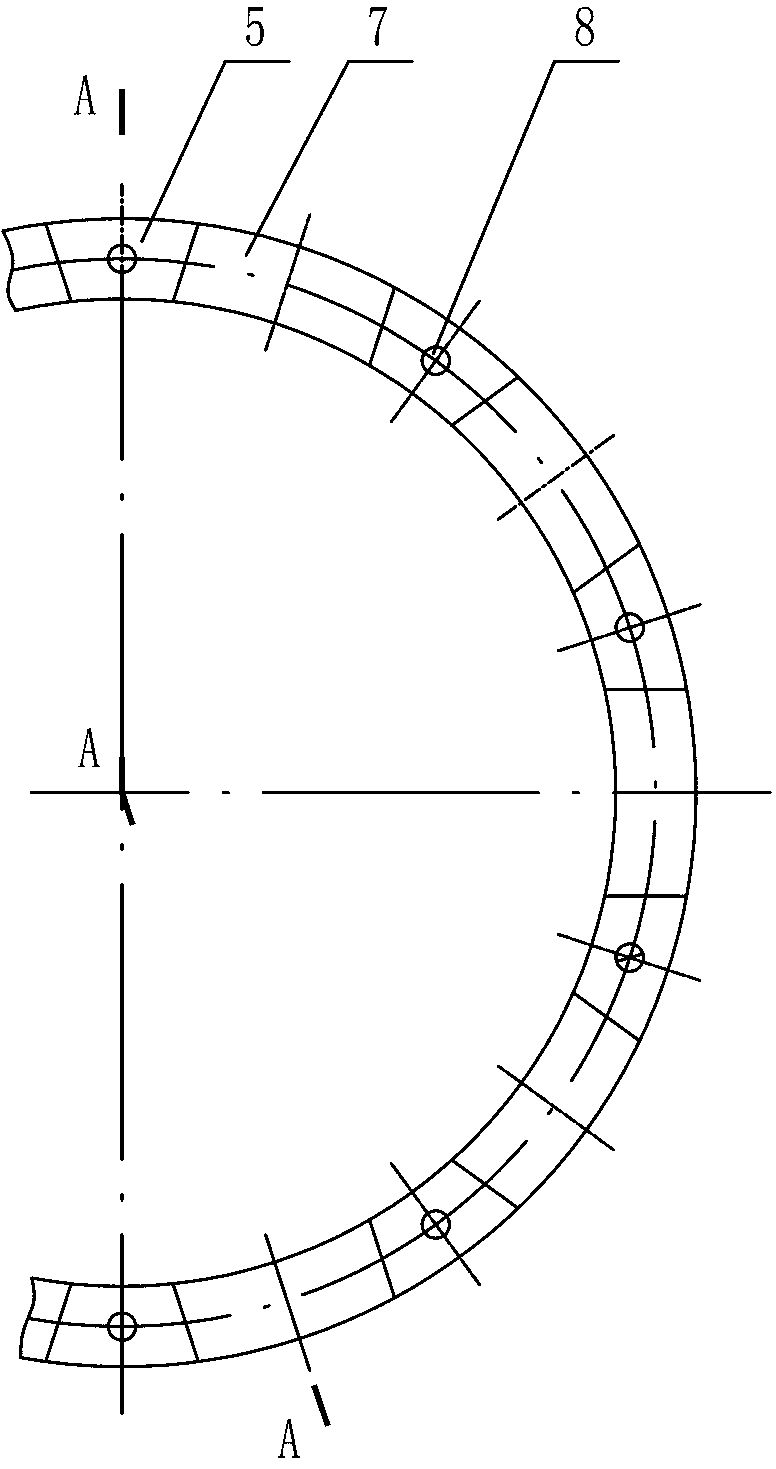

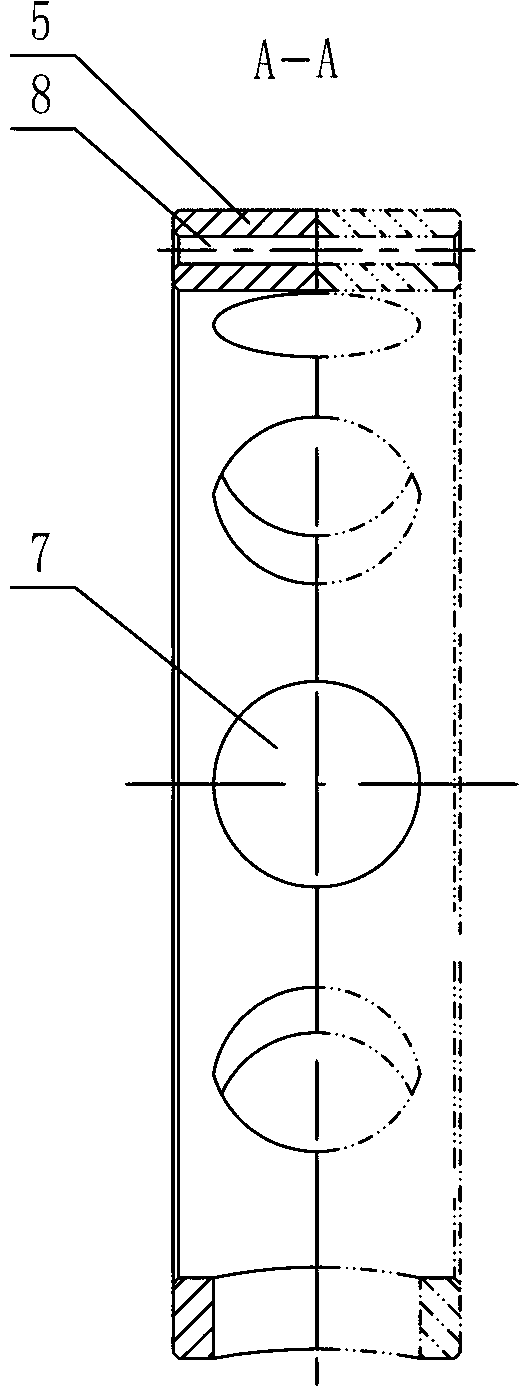

[0009] Specific implementation mode one: combine Figure 1~Figure 3 Explain that the ultra-low temperature liquid pump bearing of this embodiment includes an outer ring 1, an inner ring 2 and a plurality of spherical rolling elements 3, the outer ring 1 is set on the inner ring 2 and the two are arranged concentrically, and the inner ring of the outer ring 1 A plurality of spherical dimples 4 are evenly distributed on the circumference where the circumferential surface is located in the middle and the outer circumference of the inner ring 2 is located in the middle. A plurality of spherical dimples 4 on the outer circumferential surface of the inner ring 2 are provided in one-to-one correspondence, and a spherical rolling body 3 is arranged in each corresponding spherical dimple 4, and the width of the outer ring 1 and the inner ring 2 is equal. The bearing also includes two annular cages 5 and a plurality of tubular rivets 6. The widths of the two annular cages 5 are equal, a...

specific Embodiment approach 2

[0011] Specific implementation mode two: combination figure 1 To illustrate, the tubular rivet 6 of this embodiment is a stainless steel hollow rivet in a soft state. The undisclosed technical features in this embodiment are the same as those in the first embodiment.

specific Embodiment approach 3

[0012] Specific implementation mode three: combination figure 1 Note that the sum of the widths of the two annular cages 5 in this embodiment is 43-4 mm. The undisclosed technical features in this embodiment are the same as those in the first or second specific embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com