Beam and pillar node dry connection fan-shaped viscoelastic damper

A technology of beam-column joints and dry connections, which is applied in the direction of building components, building structures, building types, etc., can solve the performance fluctuation of viscoelastic dampers, occupy a large space, and lead viscoelastic sector dampers do not have the ability to withstand beam shear. issues of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

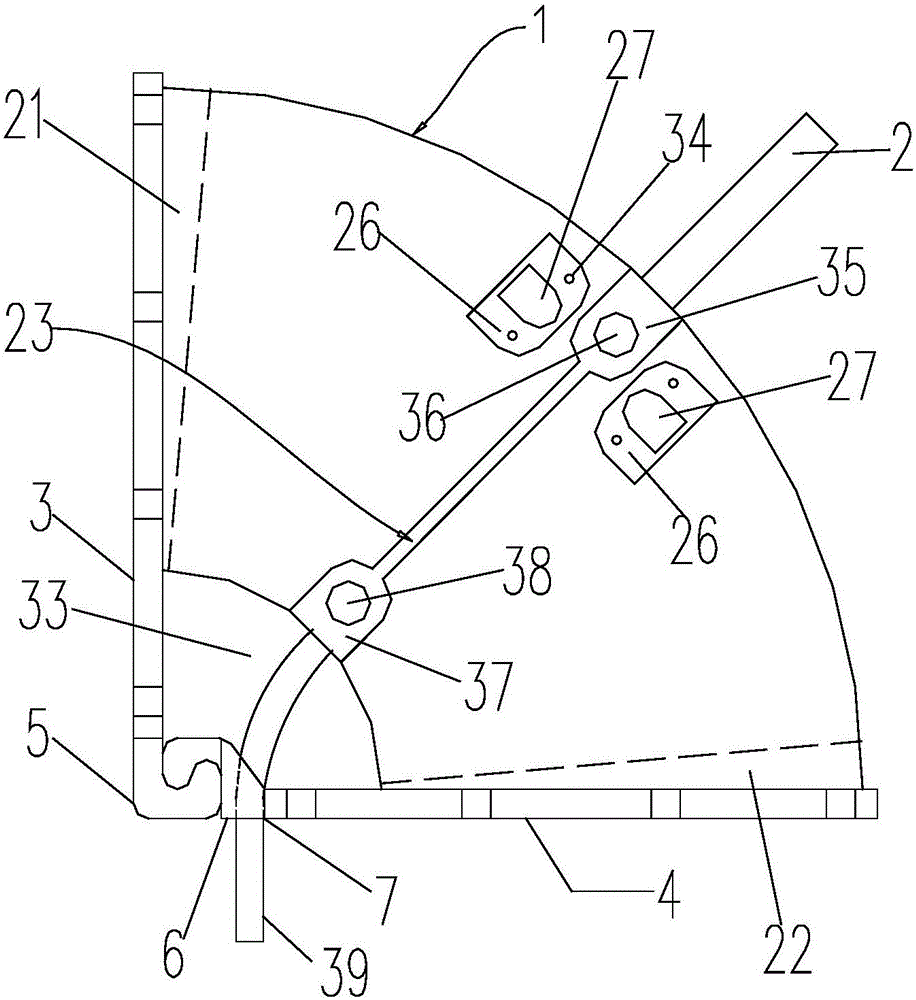

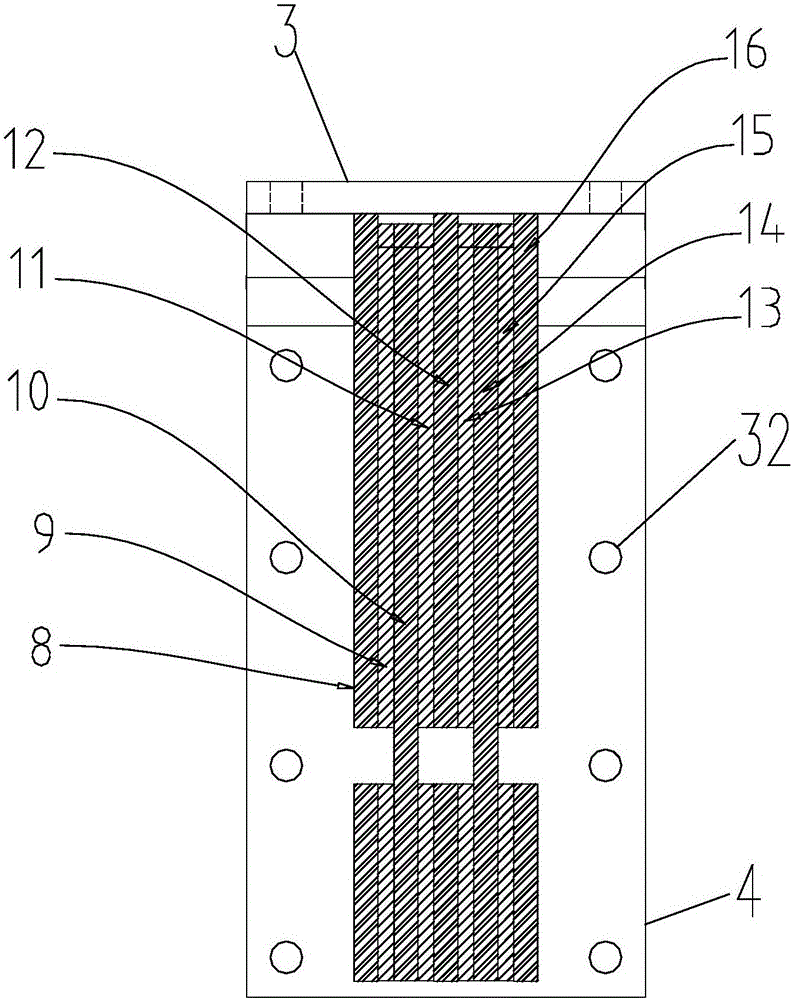

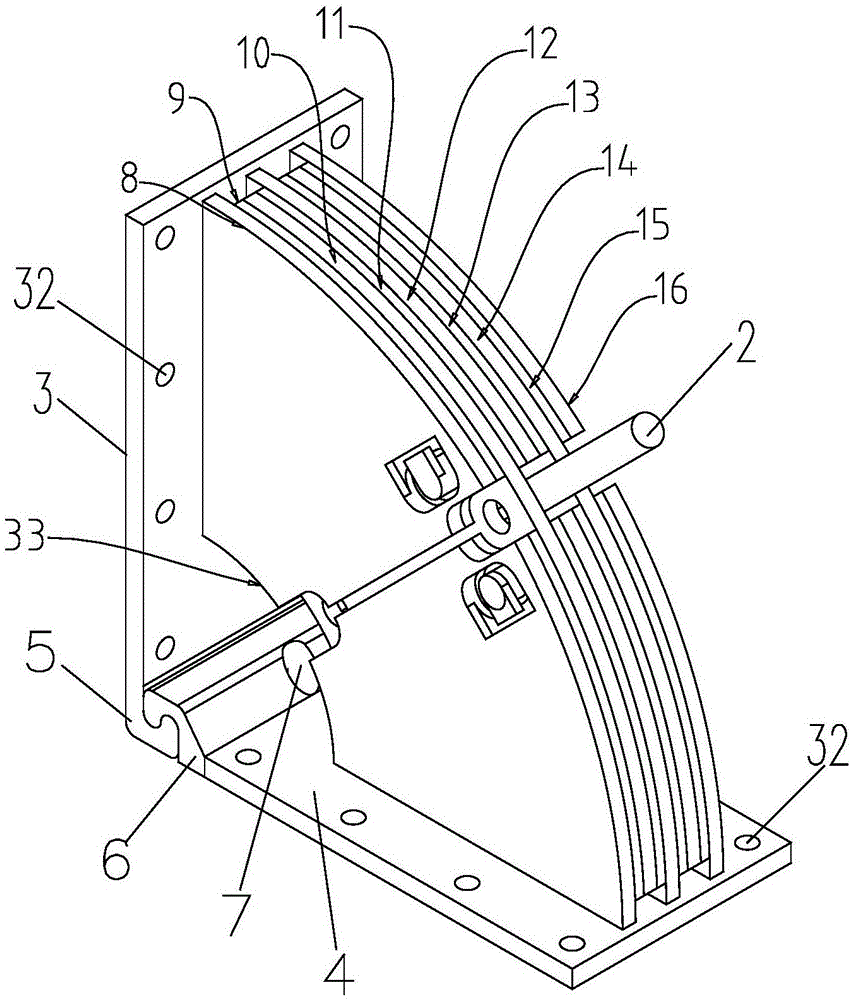

[0035] Attached below Figures 1 to 16 The present invention is further described.

[0036]Solution 1 of the present invention provides a sector-shaped viscoelastic damper for beam-column joint stem connection, which includes a composite energy-dissipating support body 1, a beam connecting plate 3, a column connecting plate 4 and a position-limiting device, the lower end of the beam connecting plate 3 and the column The left end of the connecting plate 4 has an upright U-shaped groove part one 5 and an inverted U-shaped groove part two 6 respectively, and the left side wall of the U-shaped groove part two 6 is snap-fittingly arranged In the notch, the cooperation between the U-shaped groove part one 5 and the U-shaped groove part two 6 makes the beam connection plate 3 and the column connection plate 4 have a rotation range of 80-100 degrees, that is, the beam connection plate 3 and the column connection plate The connecting plate 4 passes through the U-shaped groove part 1 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com