Cold forging extrusion concave die

A die and cold forging technology, applied in forging/pressing/hammer devices, forging/pressing/hammering machinery, transportation and packaging, etc. problems, to achieve the effect of reducing the difficulty of cutting, high mechanical properties of the product, and improving the utilization rate of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

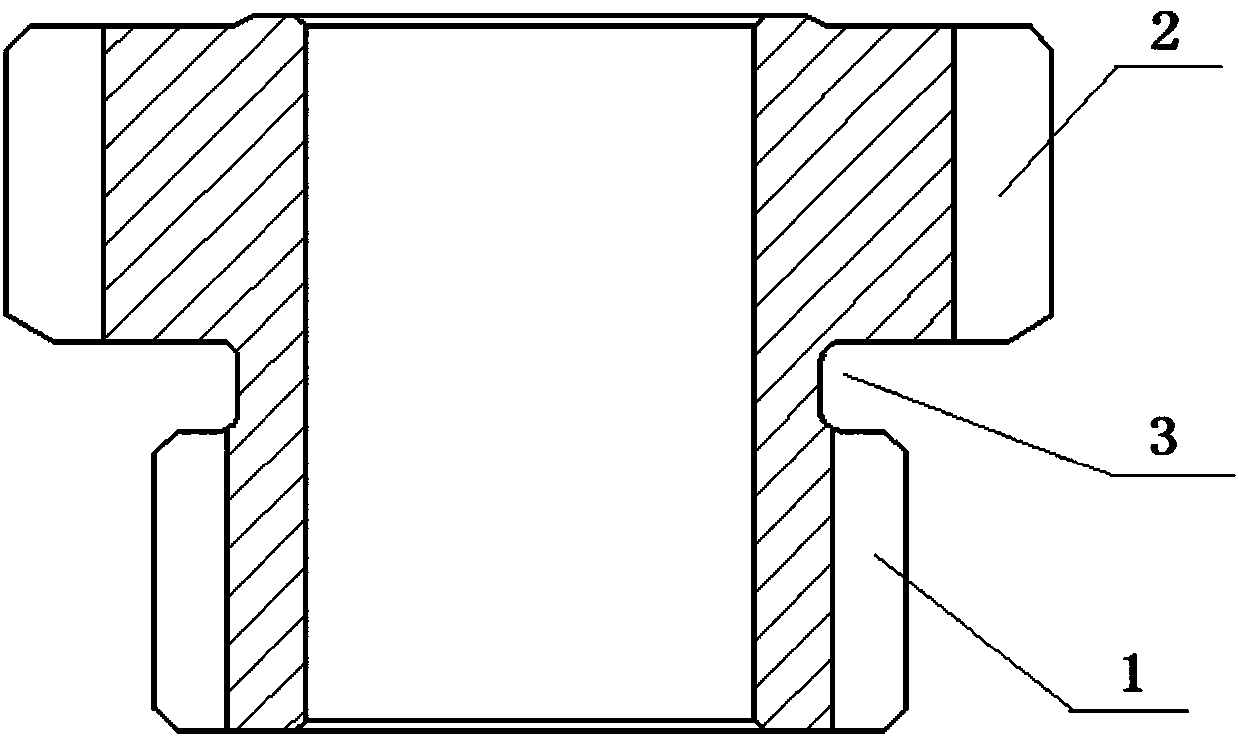

[0016] Example: see figure 1 As shown, a sun gear of an automobile automatic transmission includes a hollow shaft body, the outer surface of the hollow shaft body is provided with a primary transmission gear 1 and a secondary transmission gear 2, and the primary transmission gear 1 and secondary transmission gear 2 An annular groove 3 is arranged between them, and the first-stage transmission gear 1 and the second-stage transmission gear 2 are helical gears.

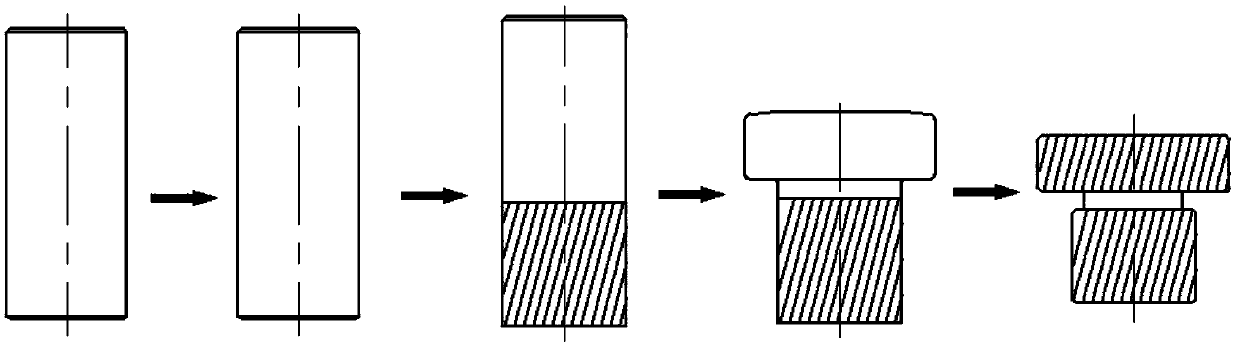

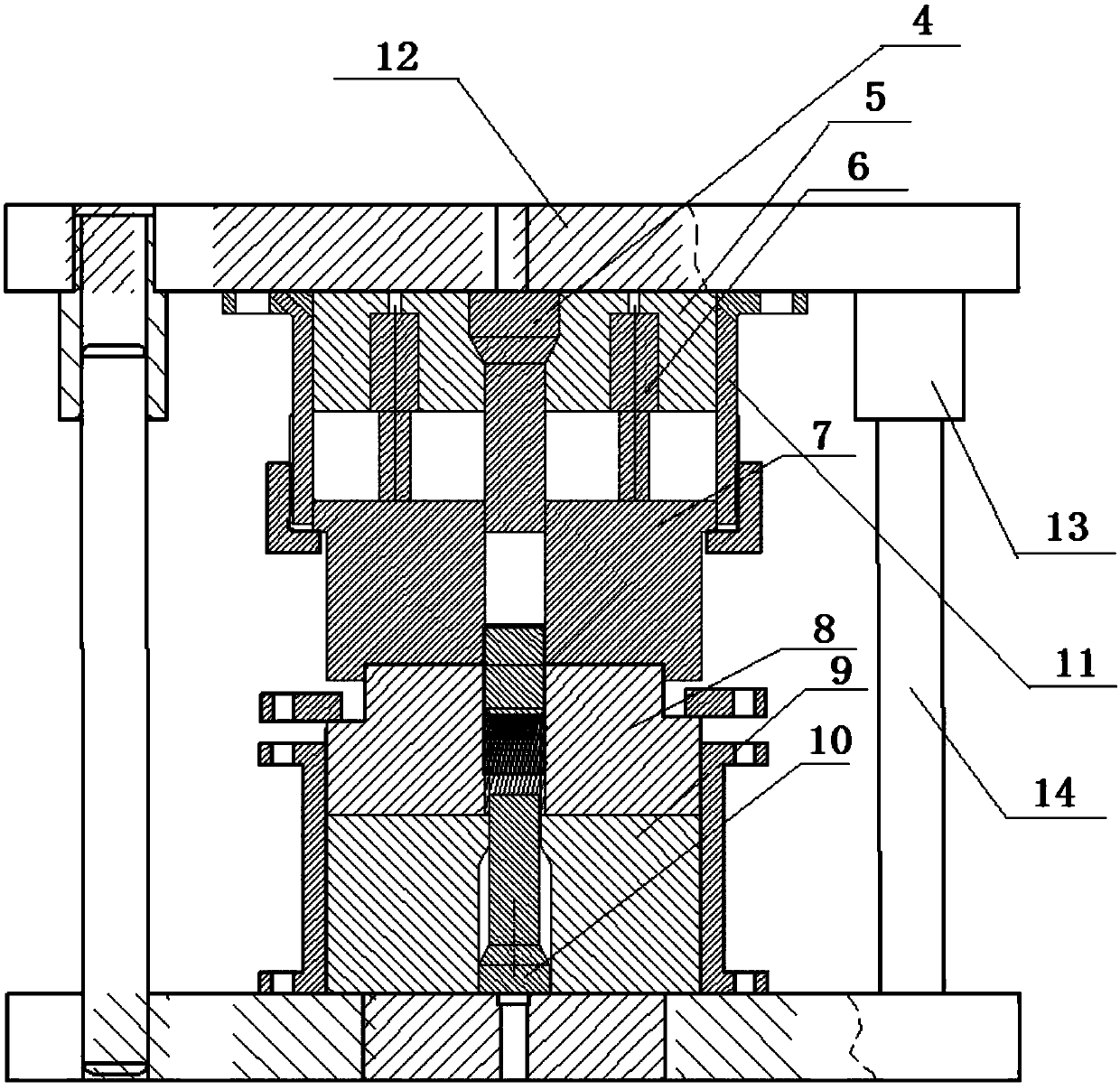

[0017] see figure 2 and image 3 As shown, the manufacturing process of the automotive automatic transmission sun gear includes the following steps: ①Blanking: Select the diameter of the bar, and cut the required length of the bar according to the size of the drawing; ②Spheroidizing annealing: Put the bar into the furnace and heat it to 720°C Spheroidizing annealing at -780°C, spheroidizing rate ≥ 90%, hardness ≤ 80HRC; ③ Billet making: peeling to remove scale and chamfering; ④ Shot blasting: Send the billet after mak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com