One-time forming mold for manufacturing channel steel pull rod

A technology for forming molds and tie rods, which is applied in the field of one-time forming molds for channel steel tie rods, which can solve the problems of unsightly product appearance, low production efficiency, and numerous processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

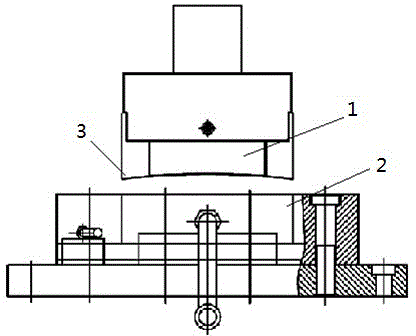

[0006] refer to figure 1 , which includes an upper die 1 and a lower die 2, the cutout 3 of the upper die is in the shape of an arc, the lower die 2 is fixed on the worktable of the punch press, and the upper die 1 is connected to the drive push rod of the punch press.

[0007] Working principle: This invention is mainly aimed at the trapezoidal groove processing of channel steel tie rods, changing the traditional processing method of gas cutting, and implementing one-time stamping forming; the one-time forming mold of channel steel tie rod punching machine is mainly composed of upper and lower molds, and the lower mold is fixed on the workbench of the punching machine , the upper die is connected to the drive push rod of the punch press; the cutout part of the upper die is designed in an arc shape instead of a plane. After a part of the workpiece is cut, it is all lowered into the shear, which can greatly reduce the tonnage requirements of the punching machine.

[0008] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com