Channel dock

A channel-type, dock technology, applied in the field of shipbuilding, can solve the problems of high investment risk in docks, and achieve the effect of saving investment and use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

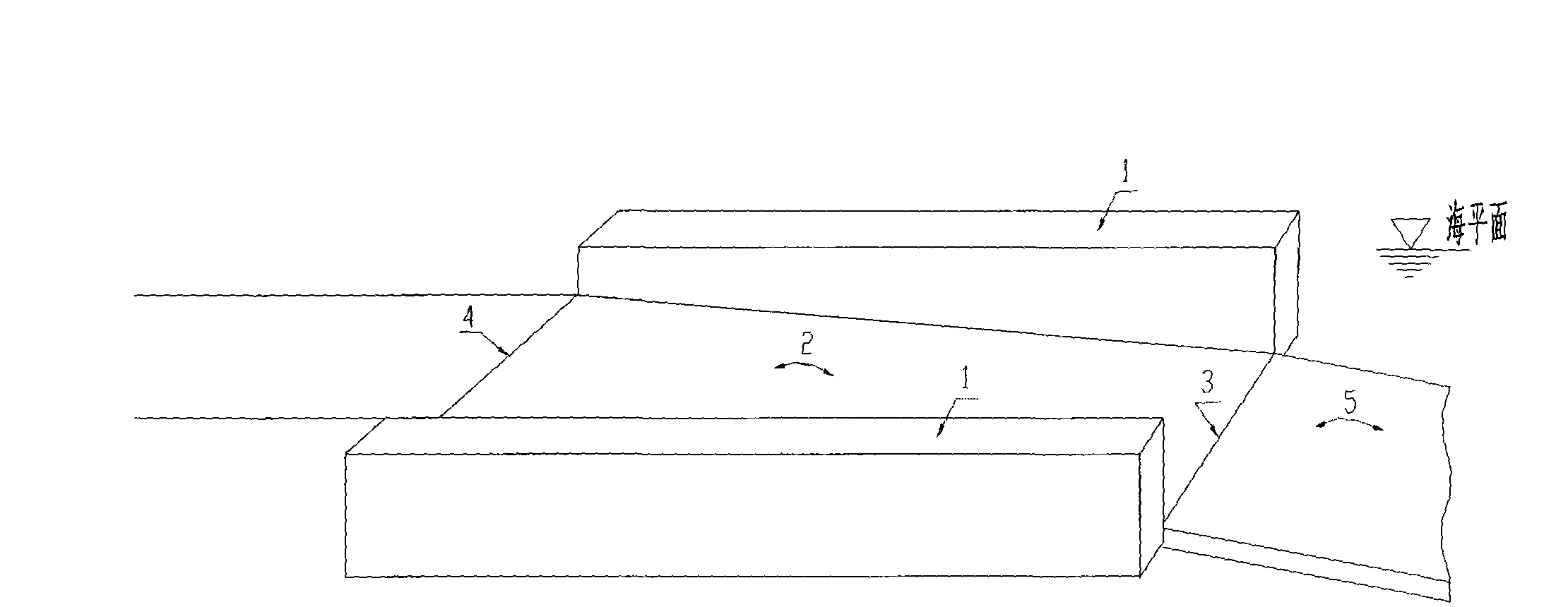

[0029] Embodiment 1, as attached figure 1 Shown, be used to build the channel type dock of 10,000-ton ship, its length is 400m, the height of the dock wall 1 on left and right sides is 16m, and several hoisting equipments are installed above.

[0030] The slope of dock bottom 2 is 1:18, and the elevation of dock mouth 3 is 1m higher than the local average high tide level. Rubber dams can be installed at dock mouth 3 with a height of 5m, which can block the invasion of extreme high tides and storm surges.

[0031] The dock stern 4 leads to the manufacturing site of the ship section, and the passage of the manufacturing site and the dock bottom 2 are connected with a transition section with a gradient gradient, so that the ship segment and materials can be transported into the dock very conveniently.

[0032] The ramp 5 in front of the dock 3 has a slope of 1:8 and a length of 40m, leading to the sea. The dock bottom 2 and the ramp 5 are connected by a transition section with a...

Embodiment 2

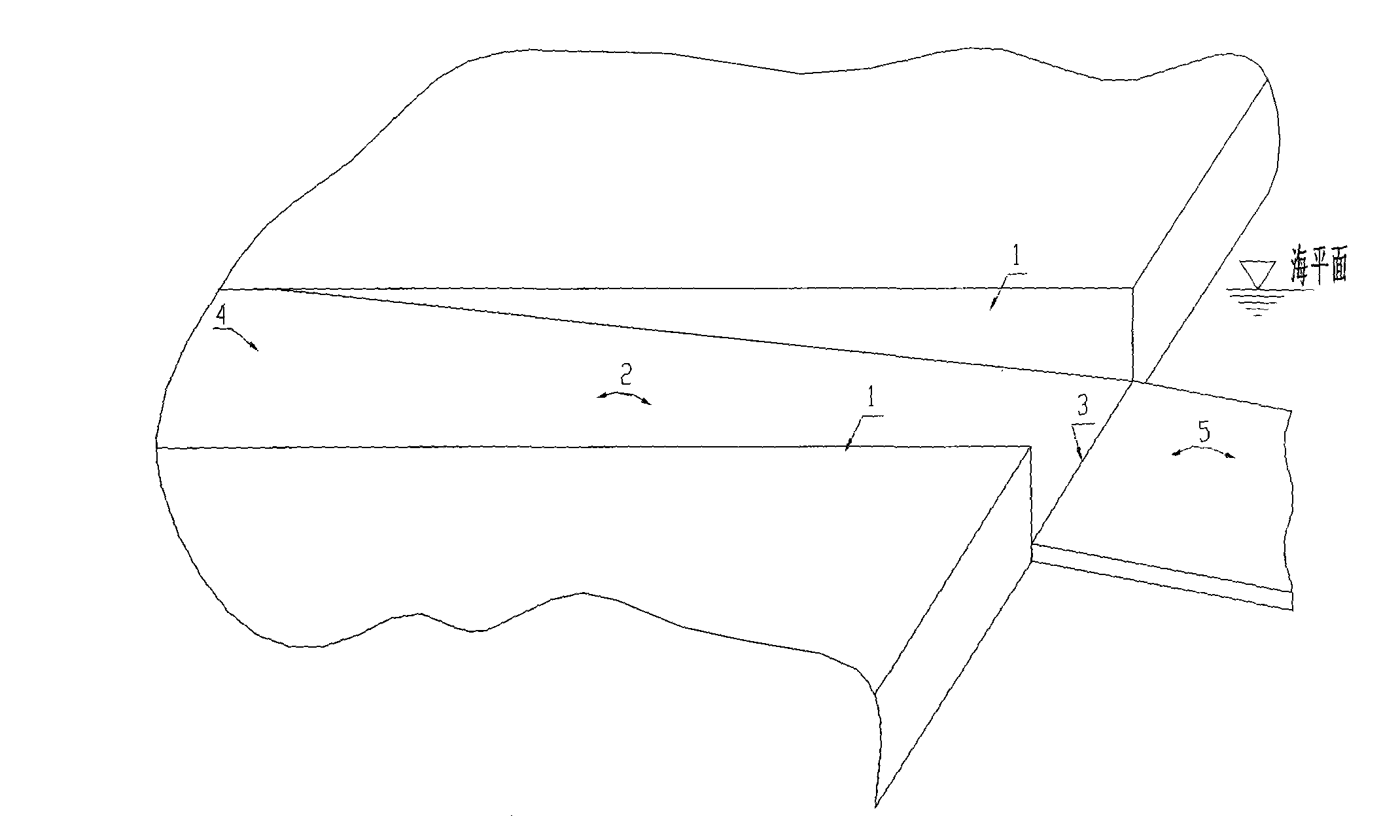

[0035] Embodiment 2, as attached figure 2 As shown, the passageway dock for building 100,000-ton ships is an embedded structure excavated according to the terrain, and its length is 1000m.

[0036] The height of the front end of the dock wall 1 on the left and right sides is 25m, the track of the lifting equipment is set on the dock wall, and several lifting equipment are installed above, and the tail of the dock wall can be connected with the track beam and the track of the gantry crane.

[0037] The slope of the dock bottom 2 is 1:200, and the elevation of the dock mouth 3 is the local high tide level. A detachable dam can be installed at the dock mouth 3, with a height of 4m, which can block the invasion of extreme high tides and storm surges.

[0038] Heavy rails are laid on the bottom of the dock 2 and the ramp 5, and the tail of the dock 4 leads to the factory building of the ship section. The passage of the factory building is connected with the bottom of the dock 2. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com