Heat dissipation substrate for mounting electric component

一种电子部件、散热基板的技术,应用在电气测量仪器的零部件、车辆部件、电气元件等方向,能够解决端子距离变窄、增大端子放电现象等问题,达到抑制发热量、降低电路布线电阻的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

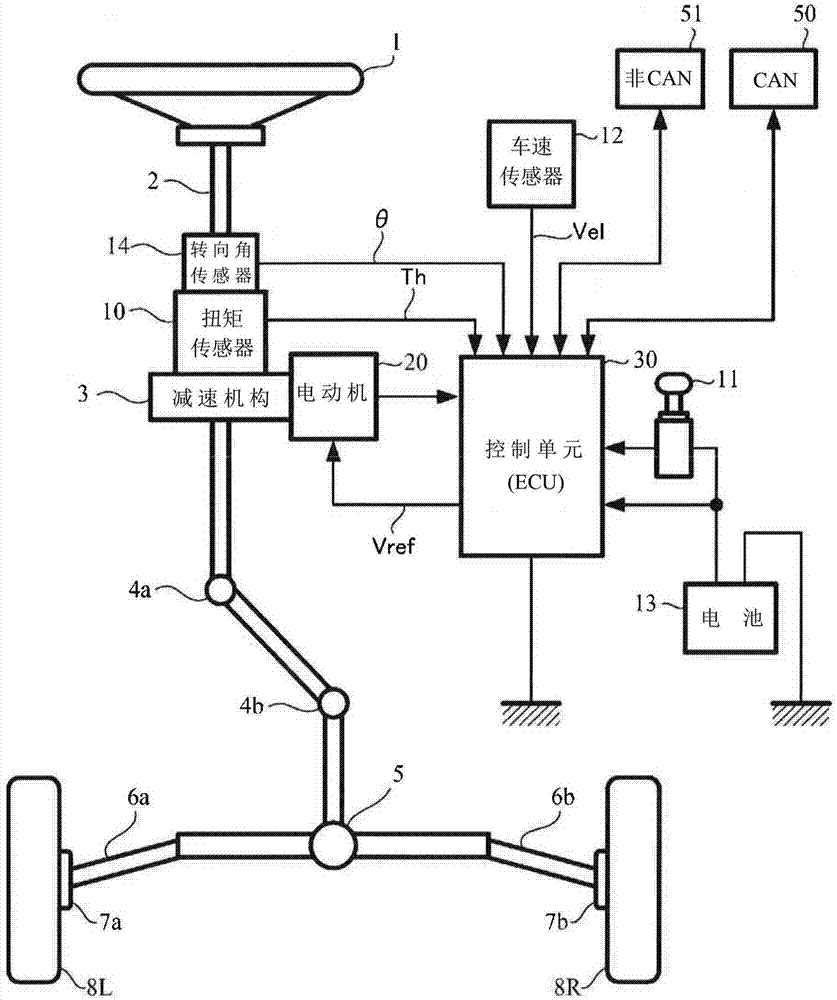

[0076] Next, an embodiment of the present invention will be described taking, as an example, a case where the control device is used in an electric power steering device mounted on a vehicle.

[0077] Here, the above-mentioned electric power steering apparatus applies a steering assist force (assist force) to a steering mechanism of a vehicle by using a rotational force of an electric motor, which passes the driving force of the electric motor through a transmission mechanism such as a gear or a transmission belt via a reduction mechanism as the steering assist force. Applied to steering shaft or rack shaft. Such an electric power steering (EPS) performs feedback control of a motor current in order to accurately generate torque of a steering assist force.

[0078] Such feedback control adjusts the motor applied voltage so that the difference between the steering assist command value (current command value) and the motor current detection value becomes smaller, and the adjustme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com