Shaping device and method for field emission electron source emitter tip

An electron source and field emission technology, which is applied in the manufacture of circuits, electrical components, electrode systems, etc., can solve the problems of large emission beam current and inability to work stably, and achieve large emission current, high angular current density, and concentrated emission direction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

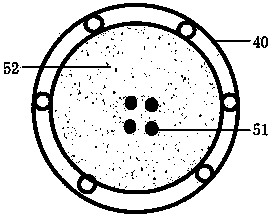

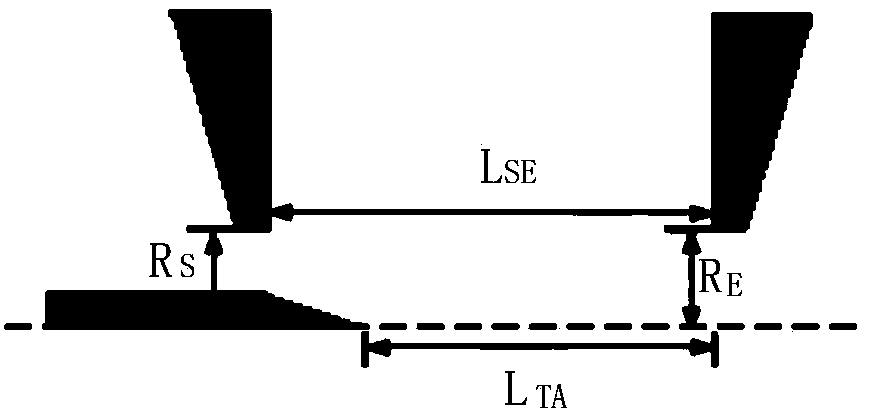

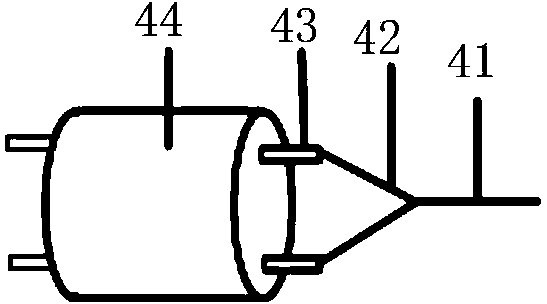

[0040] Such as figure 2 As shown, the field emission electron source emitter tip shaping device of this embodiment includes: a vacuum chamber 1, a vacuum pumping system 2, a vacuum degree measurement system 3, an electron gun assembly 4, a power supply system 5 and an electron beam imaging system 6; Wherein, the lower surface of the vacuum chamber 1 is connected to the vacuum pumping system 2 through the flange port 20, and the upper surface is connected to the vacuum degree measuring system 3 through the flange port 30; the electron gun assembly 4 is installed in the vacuum chamber 1 through the electron gun flange port 40 and connected to the power system 5 outside the vacuum chamber through conductive leads; on the surface of the vacuum chamber opposite to the electron gun assembly, an electron beam imaging system 6 is installed through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com