Multi-layer shoe sole, cloth sole shoe and manufacturing method of multi-layer shoe sole

A technology for shoe soles and uppers, which is applied in the field of shoe soles and shoes, and can solve problems such as limited styles, few consumers, and not being widely accepted by the market

Pending Publication Date: 2021-10-26

云南明湖环境科技有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] The soles of mille-soled cloth shoes are made of multiple layers of cloth, which are comfortable to wear, light and non-slip, breathable and sweat-absorbent. However, due to the limited style, they are not widely accepted by the market, and fewer and fewer consumers

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

no. 4 example

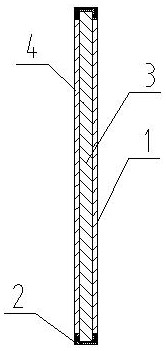

[0030] The fourth embodiment, a manufacturing method of a thousand-ply sole, the upper sole 1, the middle sole 3, and the lower sole 4 of the first embodiment are sewed with threads and then autoclaved and shaped, the autoclaved pressure is 0.3Mpa, and the autoclaved time is 24 hours , dry after autoclaving, and finally die-cast the rubber layer.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

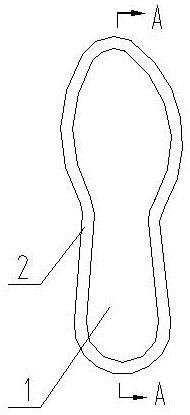

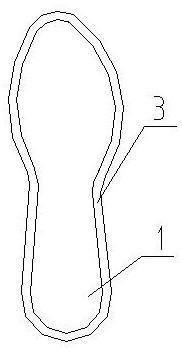

The invention discloses a multi-layer shoe sole and a cloth sole shoe, and belongs to the technical field of shoemaking, the multi-layer shoe sole comprises an upper shoe sole, a middle shoe sole and a lower shoe sole, the upper shoe sole, the middle shoe sole and the lower shoe sole are made of multi-layer cloth, the size of the upper shoe sole is 2-5 yards smaller than that of the middle shoe sole, and the size of the lower shoe sole is 2-5 yards smaller than that of the middle shoe sole. After the upper sole, the middle sole and the lower sole are combined, the middle sole protrudes outwards to form a boss, a rubber layer or a plastic layer is cast on the boss in a die mode, the cloth sole is protected and beautified, casting or bonding with an upper is facilitated, the appearance of a tourist shoe and a sneaker is achieved, and meanwhile the breathable, comfortable and anti-skid effects of a cloth shoe with a multi-layer sole are achieved. The organic combination of the traditional cloth shoe process and the existing shoe making technology is realized.

Description

technical field [0001] The invention relates to a shoe sole and a shoe, in particular to a thousand-layer shoe sole and a cloth-soled shoe. Background technique [0002] The sole of mille-soled cloth shoes is made of stacked layers of cloth. It is comfortable to wear, light and non-slip, breathable and sweat-absorbent. However, due to the limited style, it is not widely accepted by the market, and there are fewer and fewer consumers. Contents of the invention [0003] The technical problem to be solved by the present invention is to provide a new-style thousand-layer sole and cloth-soled shoes. [0004] Technical scheme of the present invention is as follows: [0005] Melaleuca sole of the present invention comprises upper sole, middle sole and lower sole, and described upper sole, middle sole and lower sole are all made of multi-layer cloth, and the size of the upper sole is smaller than that of the middle sole 2~5 yards, the size of the lower sole is 2~5 yards smaller ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A43B13/02A43B13/14A43B13/28

CPCA43B13/14A43B13/023A43B13/28

Inventor 不公告发明人

Owner 云南明湖环境科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com