Stewed-bird's-nest setting method and system

A bird's nest and shape technology, which is applied in the field of instant stewed bird's nest shaping method and shaping system, can solve the problems of long drying time of bird's nest, difficulty in dispersing uniformly, long stewing time, etc., achieve better taste, increase shaping efficiency, and short stewing time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0066] The present invention also provides a method for preparing edible gum, the specific steps of which are:

[0067] S80, preparing the reaction kettle, cleaning and disinfecting;

[0068] S81. Pour the mashed rice and water into the reactor, at 60-150°C, control the speed at 150-300rpm / min, and stir for 20-45min;

[0069] S82. Pound the sago into the reaction kettle, control the speed at 300-500 rpm / min at 70-200°C, and stir for 1-5 min;

[0070] S83. Take another container, add okra and water, and stew at 70-150°C for 30-50s to obtain okra glue;

[0071] S84. Put the okra glue and sugar glue into the reaction kettle in S82, and conduct ultrasonic reaction at 60-130° C. for 4-5 hours;

[0072] S85, the reactor is naturally cooled to room temperature;

[0073] S86. Take out the edible glue in the cooled reaction kettle for later use.

Embodiment 6

[0074] The present invention provides Example 6. The edible gum is prepared from the following raw materials in proportion by mass: 15 parts of rice; 10 parts of okra; 6 parts of sago; 3 parts of sugar gum; 20 parts of water.

Embodiment 7

[0075] The present invention provides Example 7. The edible gum is prepared from the following raw materials in proportion by mass: 30 parts of rice; 35 parts of okra; 20 parts of sago; 25 parts of sugar gum; 50 parts of water.

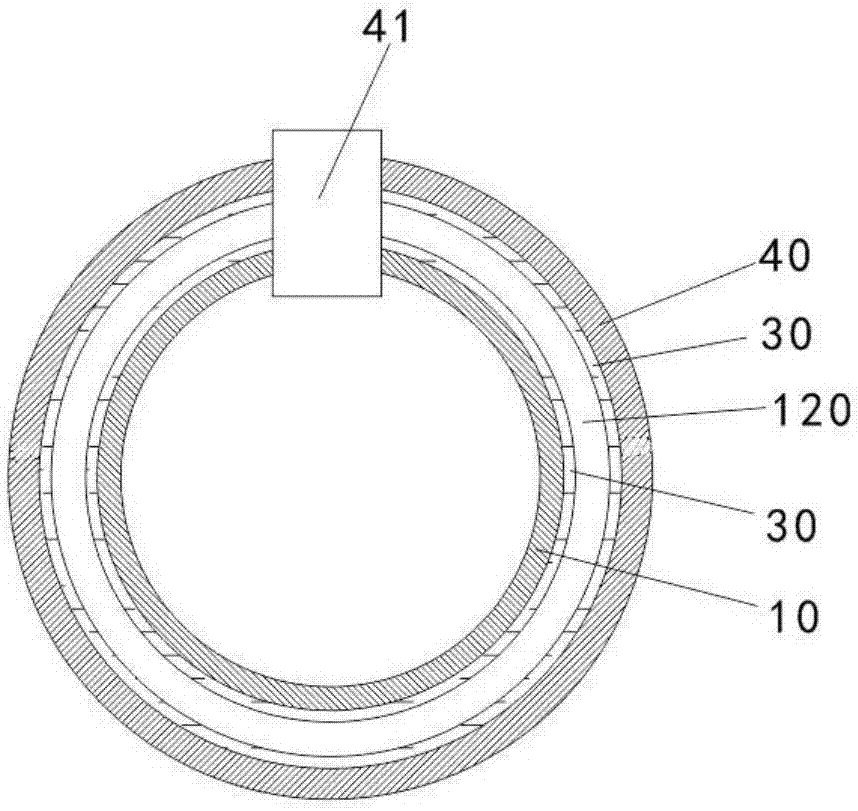

[0076] The edible glue in embodiment 6, embodiment 7 is respectively coated on the setting tube surface, and lining is wound on the setting tube surface, and experiment proves: the edible glue in embodiment 6 and embodiment 7 all can make lining adhere to the setting tube surface. The surface of the tube effectively avoids the displacement of the fabric.

[0077] Because the fabric and the surface of the shaping tube are not easy to fit, the phenomenon of relative displacement between the fabric and the surface of the shaping tube is prone to occur, so that a part of the surface of the shaping tube cannot cover the fabric, which will easily lead to the problem of reducing the quality of the bird's nest; the present invention uses rice, okra, The combi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com