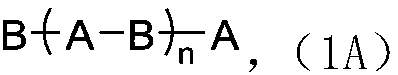

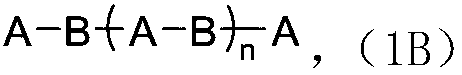

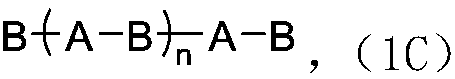

Physical split phase supramolecular dynamic polymer and application thereof

A polymer and supramolecular technology, applied in the field of smart materials, can solve the problems of hard cross-linked polymers, material failure, and inability to be reused, and achieve good processing performance, self-healing, and rich structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0151] A preferred preparation method of a dynamic polymer ionic liquid gel of the present invention includes but is not limited to the following steps: blending the raw materials for preparing dynamic polymers with ionic liquids, so that the mass fraction of raw materials for preparing dynamic polymers is 0.5- 70%, polymerization, coupling or other types of chemical reactions are carried out through the appropriate means, and after the reaction is completed, a dynamic polymer ionic liquid gel is produced. The preferred preparation method of another dynamic polymer ionic liquid gel of the present invention includes but not limited to the following steps: the raw materials of the block polymer and the metal center are swollen in a solvent containing an ionic liquid, and the The mass fraction of the block polymer is 0.5-70%, and after fully swelling, the solvent is removed to form a dynamic polymer ion liquid gel. The block polymer molecule for preparing the ionic liquid gel is ...

Embodiment 1

[0212] Commercially available styrene-butadiene-styrene triblock copolymer (SBS), 4-pyridinemethanol, 2-(tert-butoxycarbonyl-amino)ethanethiol and photoinitiator benzyldimethyl The ketal (BDK) is reacted in tetrahydrofuran, and the molar ratio of alkenyl to 4-pyridylmethanol, 2-(tert-butoxycarbonyl-amino)ethanethiol and BDK in the polybutadiene segment is kept at about 50: 5:5:1, the modified SBS containing both hydrogen bond groups and ligand groups of the present invention was obtained. Commercially available SBS, 4-pyridine mercaptan and photoinitiator BDK were reacted in tetrahydrofuran, keeping the molar ratio of alkenyl in the polybutadiene segment to 4-pyridine mercaptan and BDK being about 50:5:1, After the reaction is complete, silver nitrate solution is added to keep the molar ratio of silver ions to pyridyl groups at about 1:2, and a modified SBS containing only ligand groups in the soft segment is obtained. Commercially available SBS, 2-(tert-butoxycarbonyl-amino)...

Embodiment 2

[0215] Under anhydrous and oxygen-free conditions, ethyl isocyanate was reacted with equimolar equivalents of 1-amino-2,3-propanediol to obtain diol compound 2a with ureido groups in side groups. React 3 molar equivalents of [2,2':6',2"-terpyridine]-5,5"-dimethanol, 5 molar equivalents of compound 2a, and 7 molar equivalents of polycaprolactone terminated by carboxyl groups at both ends. Under the catalysis of dicycloethylcarbodiimide (DCC) and 4-dimethylaminopyridine (DMAP), a polyester chain segment containing a terpyridine skeleton ligand group and a side urea group is obtained at both ends of the hydroxyl group. Using benzoyl peroxide (BPO) as an initiator and mercaptoacetic acid as a chain transfer agent to initiate styrene polymerization at 90-100°C, keeping the molar ratio of initiator, monomer, and chain transfer agent at 1:30:1, to obtain Single carboxyl terminated polystyrene. 1 molar equivalent of the resulting copolymer segment and 2 molar equivalents of single-en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com