Balanced varnishing device based on varnished wire processing

An enameled wire, balanced technology, applied in printing devices, general parts of printing machinery, printing and other directions, can solve the problems of enameled wire surface non-roundness, increased unevenness of paint film, etc., to improve the uneven paint surface, avoid paint surface uneven effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

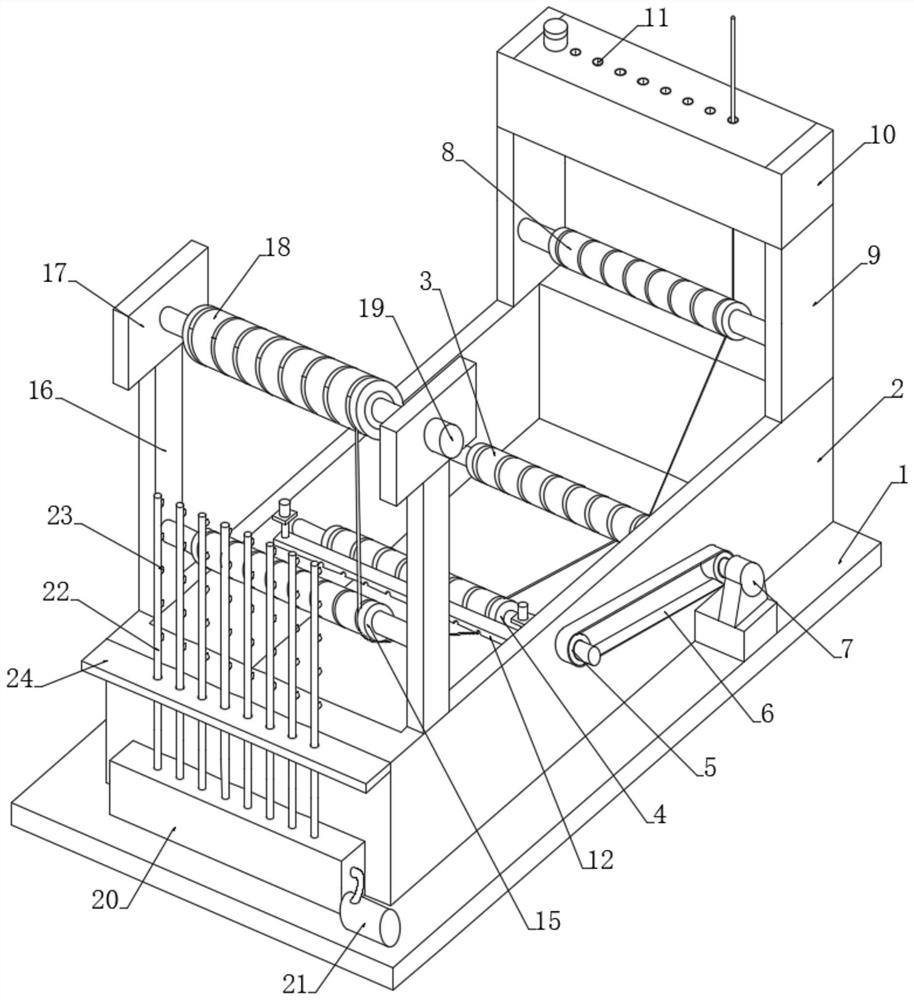

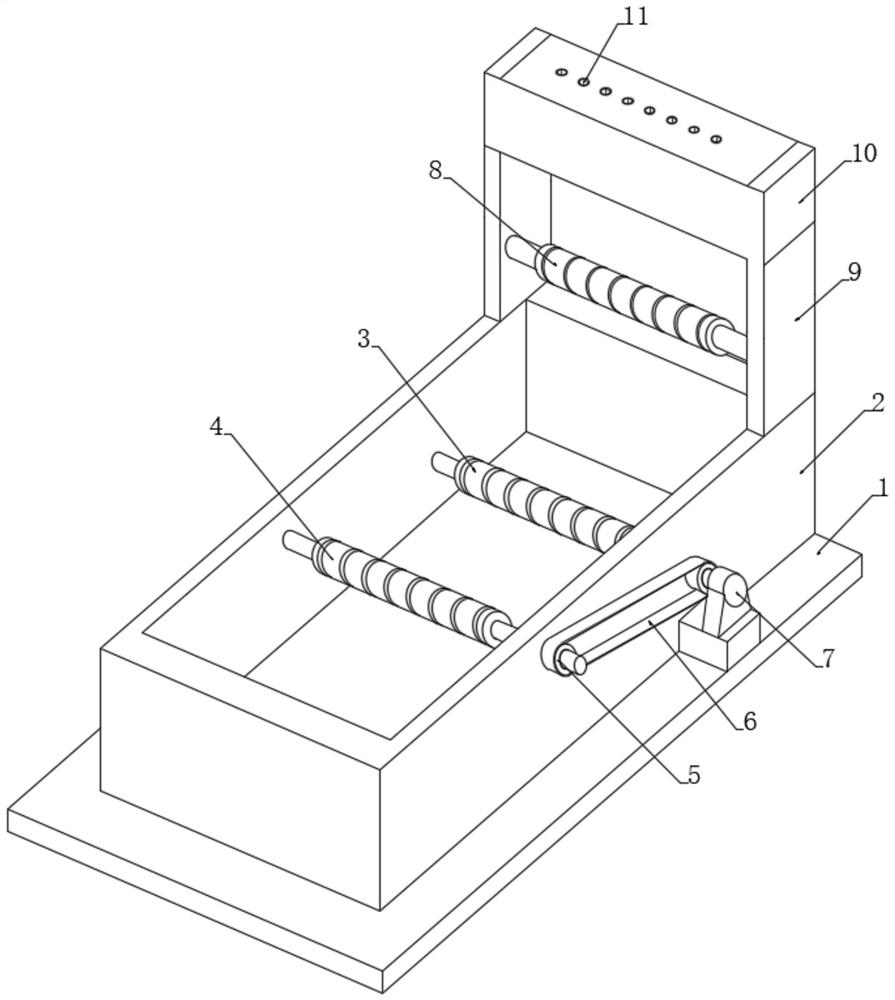

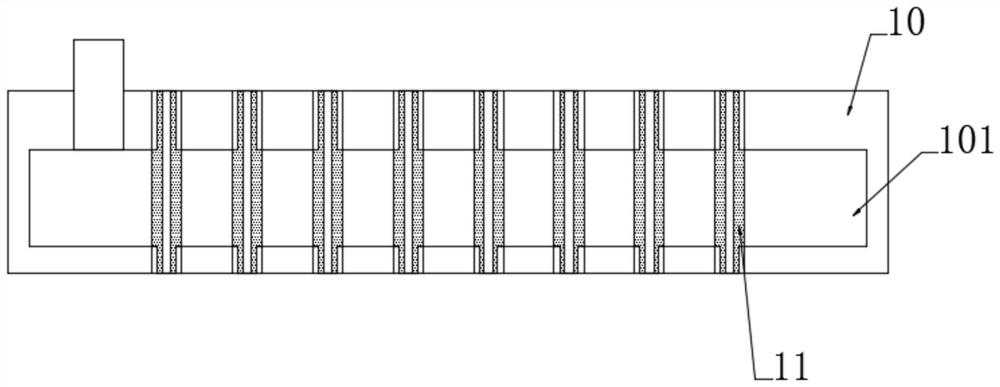

[0035] see Figure 1-2, a balanced painting device based on enameled wire processing, including a base 1 and a paint box 2 fixedly installed on the top of the base 1, the upper and lower ends of the paint box 2 are respectively installed with a lower printing roller 3 and an upper printing roller 4, and the lower printing and dyeing roller The side walls of the roller 3 and the upper printing and dyeing roller 4 are provided with multiple sets of ring-shaped dipping chambers along their horizontal direction. The ring-shaped dipping chambers are covered with ring-shaped dipping felts. In the dipped felt, the lower printing roller 3 is located below the upper printing roller 4, the upper printing roller 4 is located above the side of the lower printing roller 3, and one end of the lower printing roller 3 and the upper printing roller 4 penetrates the paint box 2 and is fixedly connected with a rotating shaft, the lower printing and dyeing roller 3 and the upper printing and dyei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com