Coding colored tape coating machine

A coating machine and color coding technology, applied in the field of coating machines, can solve the problems of affecting the coating quality and the inability to apply the coating evenly, so as to achieve the effect of improving the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

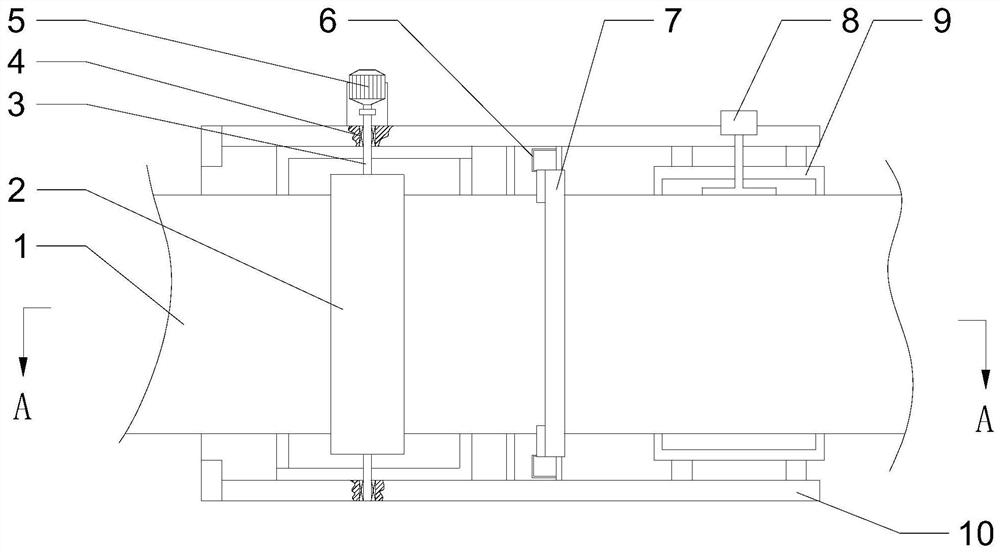

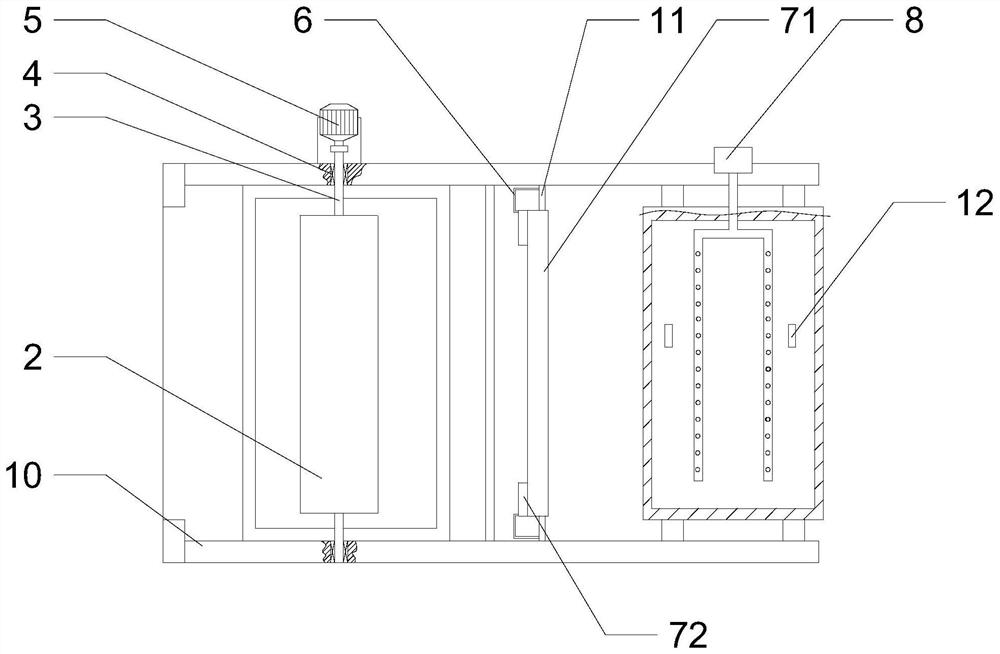

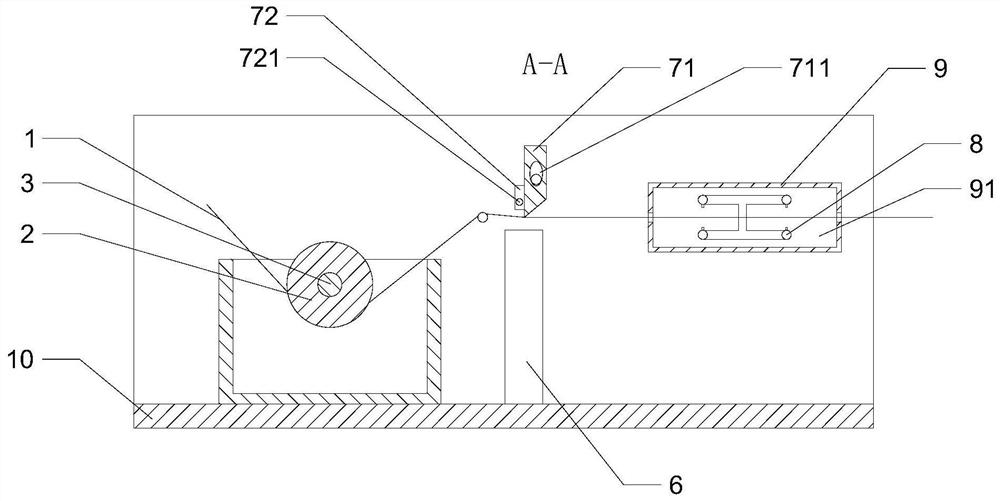

[0028] Such as Figure 1-5 As shown, a coding ribbon coating machine includes a frame 10, a first rotating shaft 3 is installed through a bearing 4 on the frame 10, a coating roller 2 is installed on the first rotating shaft 3, and one end of the first rotating shaft 3 is installed There is a power mechanism, and a second rotating shaft 11 is also installed on the frame 10, and a smoothing mechanism 7 is installed on the second rotating shaft 11 along its length direction, and the smoothing mechanism 7 includes a smoothing block 72 formed into one with each other and two outlets. Material block 71, two discharge blocks 71 are positioned at the both sides of plastering block 72, discharge port 711 is arranged on the discharge block 71, and the material receiving box 6 that is positioned at the discharge port 711 below is installed on the frame 10, the first The two rotating shafts 11 pass through the smoothing block 72 .

[0029] Working principle: When coating 1 needs to be c...

Embodiment 2

[0032] Such as Figure 1-5 Shown, on the basis of above-mentioned embodiment 1, present embodiment provides the preferred structure that coating 1 can be dried, and promptly is positioned at the rear of smoothing mechanism 7 on frame 10 and is also equipped with drying mechanism, and drying mechanism includes installation In the drying box 9 on the frame 10, a drying cavity 91 is arranged in the drying box 9, a feeding nozzle is arranged at the front portion of the drying box 9, and a discharge nozzle is arranged at the rear portion, and a device extending to the drying cavity is installed on the frame 10. Air-drying assembly 8 in 91; Air-drying assembly 8 comprises the fan 83 that is installed on the frame 10, and the main air duct 82 that extends in the drying chamber 91 is installed on the fan 83, is connected with vertical pipe 87 on the main air duct 82, The upper end of the vertical pipe 87 is connected with the upper air duct unit, and the lower end is connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com