Phase-change microcapsule based on inorganic shell layer and preparation method and application thereof

A technology of phase-change microcapsules and manufacturing methods, which is applied in the direction of microcapsule preparation, microsphere preparation, chemical instruments and methods, etc., can solve the problems that the encapsulation effect and enthalpy retention rate cannot be well considered, and achieve excellent enthalpy value The effect of retention rate, stable performance and excellent packaging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

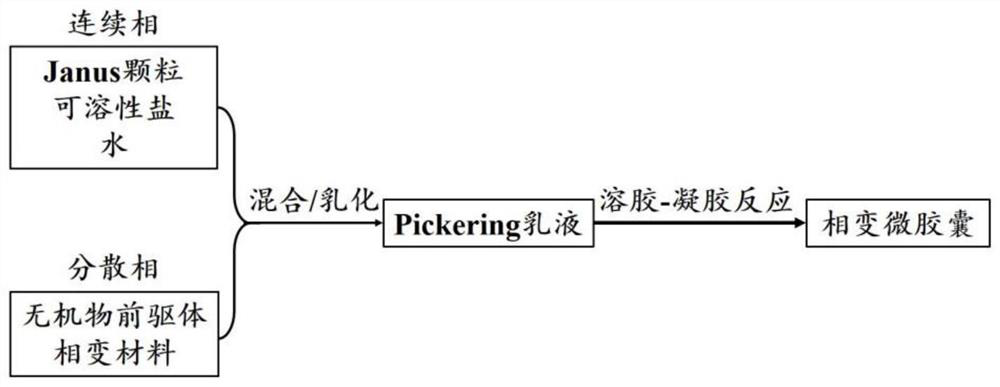

Method used

Image

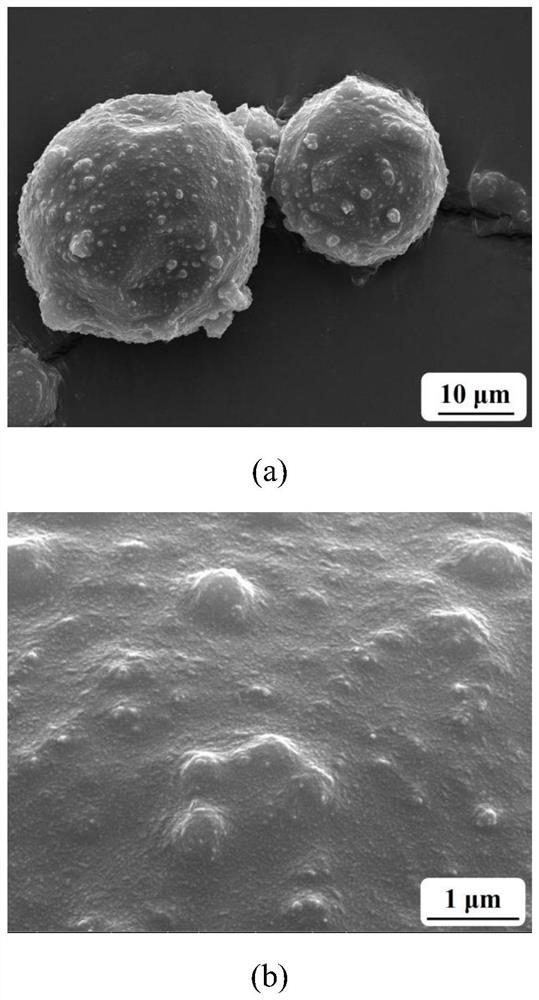

Examples

preparation example Construction

[0105] There is no particular limitation on the preparation method of Janus particles, and Janus particles can be prepared by methods commonly used in the art. For example, it can be prepared by surface selective modification, emulsion polymerization, seed emulsion polymerization, phase separation, microfabrication and self-assembly, dispersion polymerization, etc.

[0106] In some preferred embodiments, the preparation method of Janus particles of the present invention can refer to the preparation method of Janus particles disclosed in Chinese patent application CN105440218A, for example. Specifically, the preparation method of the Janus particles of the present invention comprises the following steps: dispersing the polymer particles in water to obtain a seed solution; emulsifying a silane coupling agent, an emulsifier, an initiator, etc. and adding them to the seed solution; The polymerization reaction is carried out to obtain a suspension of Janus particles; the obtained s...

Embodiment 1

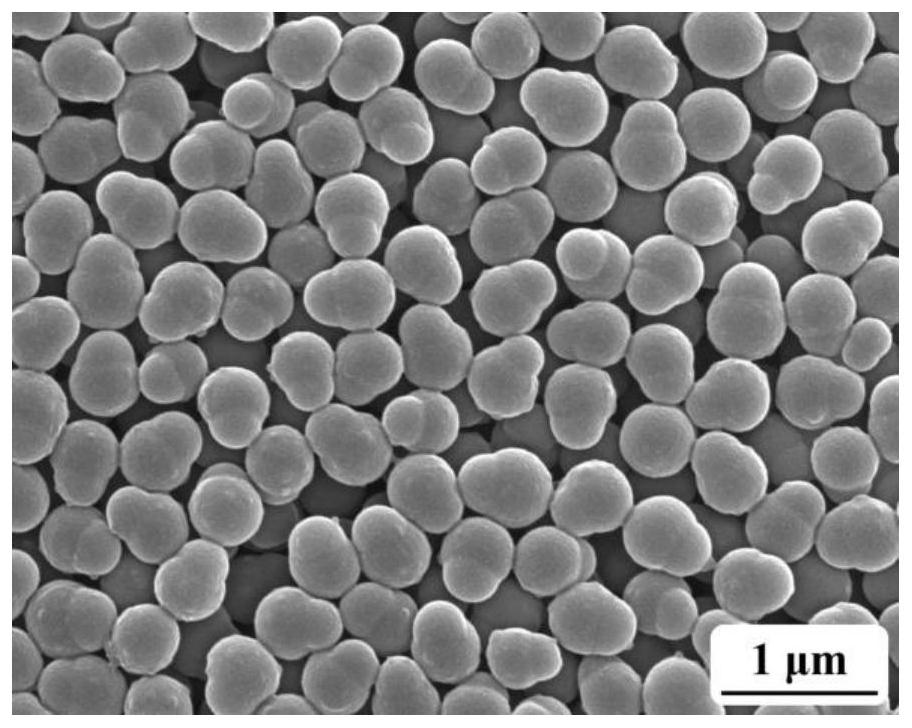

[0182] SiO 2 - Preparation of PS Janus particles

[0183] 0.15 g of azobisisobutyronitrile (AIBN) was dissolved in 15.00 g of divinylbenzene (DVB), and 0.15 g of sodium dodecyl sulfate (SDS) was dissolved in 800.00 g of water. The above two solutions were mixed and ultrasonically emulsified for 3 minutes to obtain DVB monomer emulsion. Then 25.00 g of freeze-dried HP-433 polystyrene (PS) hollow spheres were dispersed into the above-mentioned monomer emulsion. Stir at room temperature for 8 hours to induce DVB to swell PS hollow spheres. Then the temperature was raised to 70° C. and reacted for 12 hours to obtain a cross-linked PS hollow sphere dispersion. Finally, dry powder of seed balls was obtained by washing with ethanol and water and freeze-drying. Disperse 10.00 g of dry powder of seed balls in 200.00 g of water, and raise the temperature of the system to 70°C. Add 6.00g of 3-(methacryloyloxy)propyltrimethoxysilane (MPS), 6.00g of 1wt% potassium persulfate (KPS)...

Embodiment 2

[0190] SiO 2 - Preparation of PS Janus particles

[0191] SiO 2 -PS Janus particles were prepared similarly to Example 1, except that the amount of 3-(methacryloxy)propyltrimethoxysilane (MPS) used was changed to obtain larger silica ends. The specific steps are as follows: 0.15 g of azobisisobutyronitrile (AIBN) was dissolved in 15.00 g of divinylbenzene (DVB), and 0.15 g of sodium dodecyl sulfate (SDS) was dissolved in 800.00 g of water. The above two solutions were mixed and ultrasonically emulsified for 3 minutes to obtain DVB monomer emulsion. Then 25.00 g of freeze-dried HP-433 polystyrene (PS) hollow spheres were dispersed into the above-mentioned monomer emulsion. Stir at room temperature for 8 hours to induce DVB to swell PS hollow spheres. Then the temperature was raised to 70° C. and reacted for 12 hours to obtain a cross-linked PS hollow sphere dispersion. Finally, dry powder of seed balls was obtained by washing with ethanol and water and freeze-drying. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition enthalpy | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com