Patents

Literature

171results about How to "Achieve wrapping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

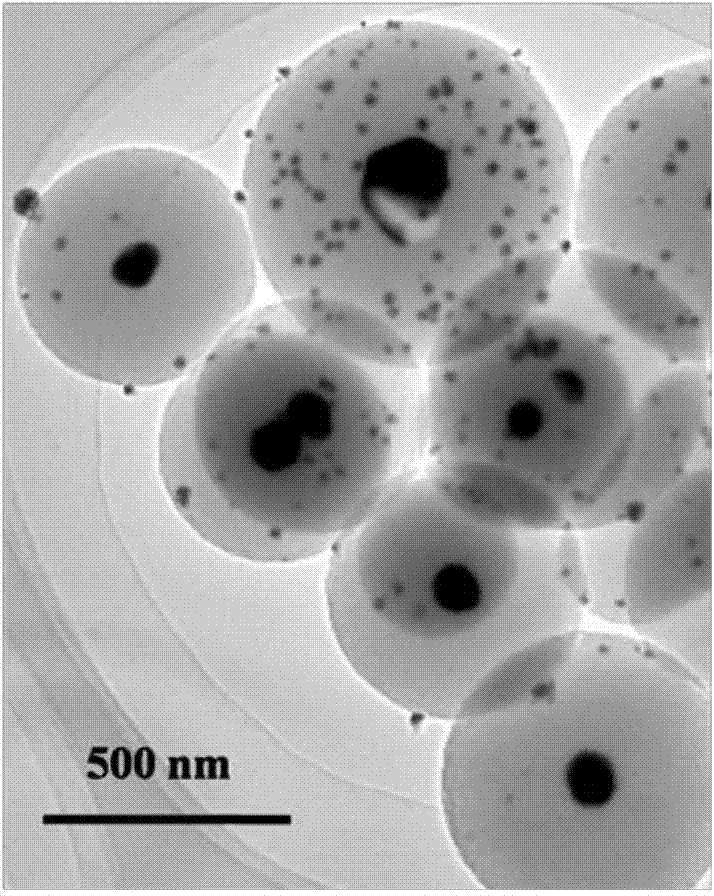

Oxidized graphene or graphene/inorganic particle core/shell material and preparation method thereof

ActiveCN102343239AExpand application spaceChange surface propertiesMicroballoon preparationMicrocapsule preparationInorganic particleInorganic particles

The invention firstly discloses an oxidized graphene or graphene / inorganic particle core / shell material which is formed by electrostatic self-assembly, wherein inorganic particles are taken as the core of the material, oxidized graphene or graphene is taken as a shell layer, and the content of the oxidized graphene or the graphene is 0.1-2wt% of that of the inorganic particles. The invention alsodiscloses a preparation method of the oxidized graphene or graphene / inorganic particle core / shell material. Therefore, a new species is added for outer-coated inorganic powder materials and the application space of the inorganic particles is expanded; furthermore, the electrostatic self-assembly technology is further applied to the preparation of the oxidized graphene or graphene-inorganic powderhybrid material, and the method simultaneously has the characteristics of being mature and environmentally-friendly in process, being simple to operate, having no need of complex equipment, being easy for realization of large-scale production and the like.

Owner:SICHUAN UNIV +1

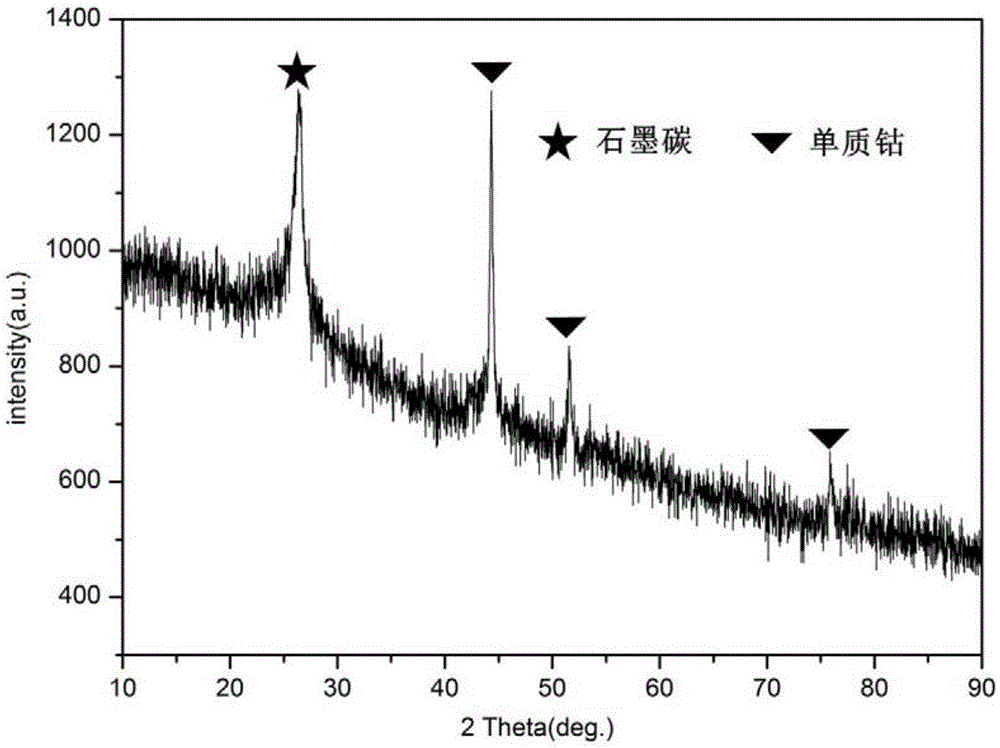

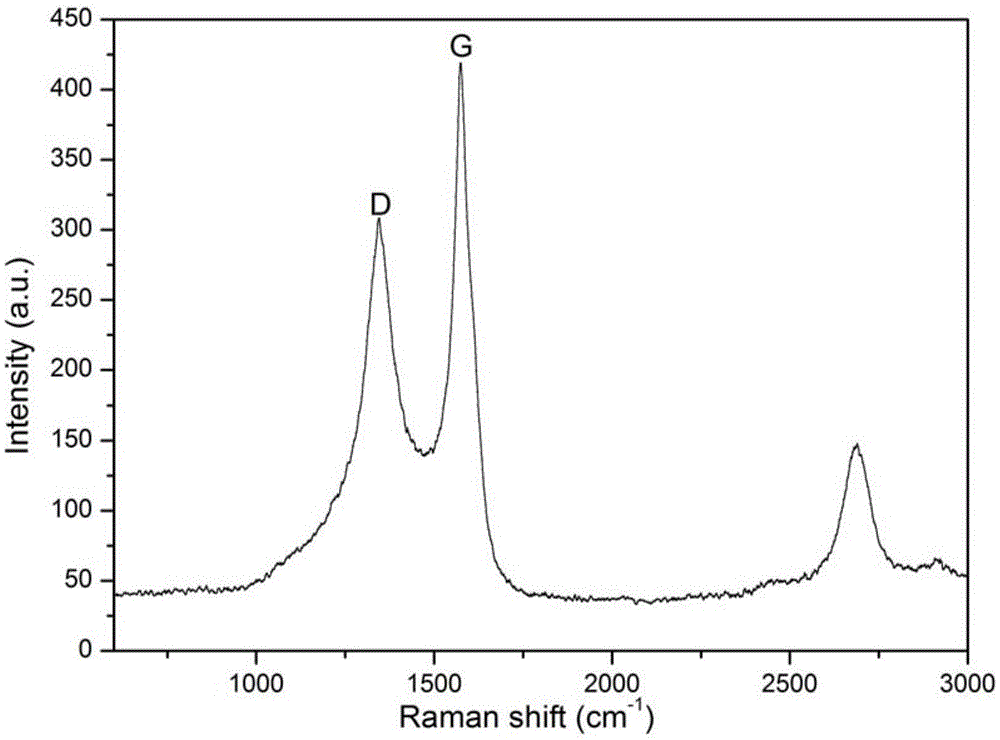

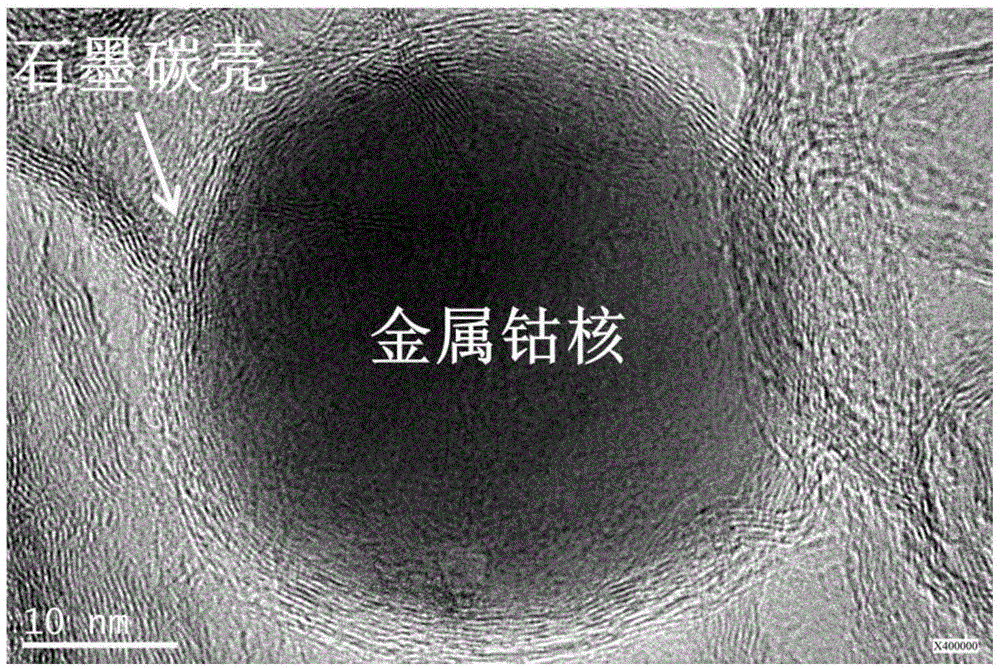

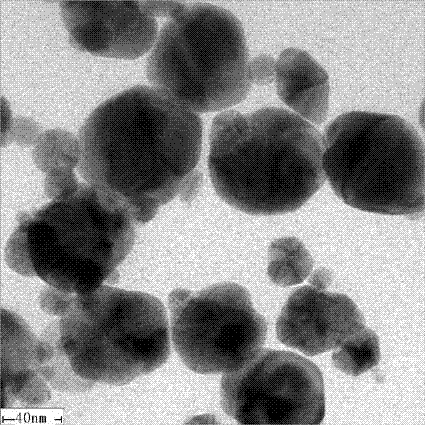

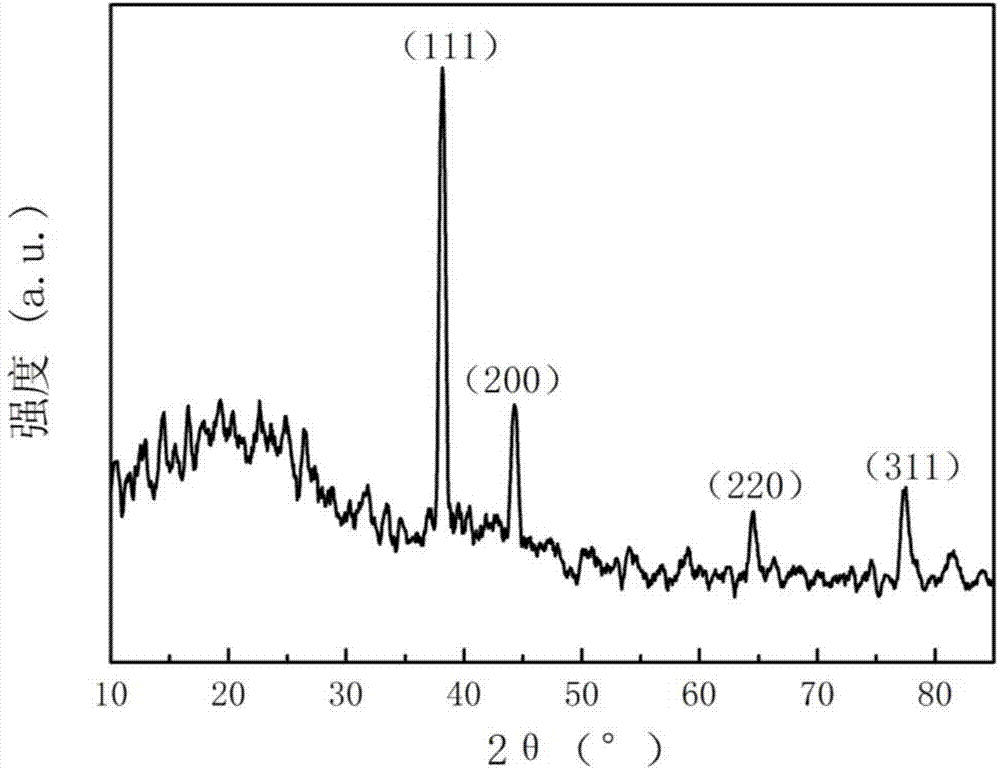

Method for preparing non-metallic element doped carbon coated metal nanoparticle magnetic composite

ActiveCN105478755AGood dispersionHigh purityTransportation and packagingMetal-working apparatusDispersityCyanamide compound

The invention discloses a method for preparing a non-metallic element doped carbon coated metal nanoparticle magnetic composite. The method comprises the steps that water-soluble metal divalent salt, a cyanamide compound and a nitrogen or boron or sulfur containing non-metallic compound are added into a methanol solution to be mixed, dissolved, dried and ground, and obtained homogeneous-phase powder is subjected to roasting pyrolysis under the protection of inert gas; and a pyrolysis product is subjected to acid pickling, washing, drying and grinding, and a target product is obtained. According to the whole preparing process of the method, metal ion reduction, metal nanoparticle coating and doping of nitrogen / boron / sulfur and other non-metallic elements are achieved in one step. The composite prepared through the method is high in degree of graphitization, good in dispersity between particles and high in purity, and the preparing method has the advantages that the cost is low, the process is simple, and large-quantity synthesis can be easily achieved.

Owner:合肥庐阳科技创新集团有限公司

Method for preparing nano Ag/PVP (polyvinyl pyrolidone) composite material by utilizing ultraviolet irradiation

The invention discloses a method for preparing a nano Ag / PVP (polyvinyl pyrolidone) composite material by utilizing ultraviolet irradiation. According to the invention, an N-vinyl pyrolidone NVP monomer is polymerized by adopting ultraviolet irradiation to generate polyvinyl pyrolidone PVP, and simultaneously, Ag<+1> is reduced to Ag particles by utilizing ultraviolet irradiation, and the Ag particles are aggregated to form nano Ag which is dispersed in PVP so as to obtain the effectively dispersed nano Ag / PVP composite material. By using the method, a condition that addition of a metal reducing agent perplexes a reaction system and influences the property of the material is avoided; and simultaneously, a polymer PVP is utilized to clad nano metal particles, thus the problem that the nano particles are easy to aggregate is effectively solved, and a composite material having a specific nano effect is prepared.

Owner:HEFEI GENIUS NEW MATERIALS

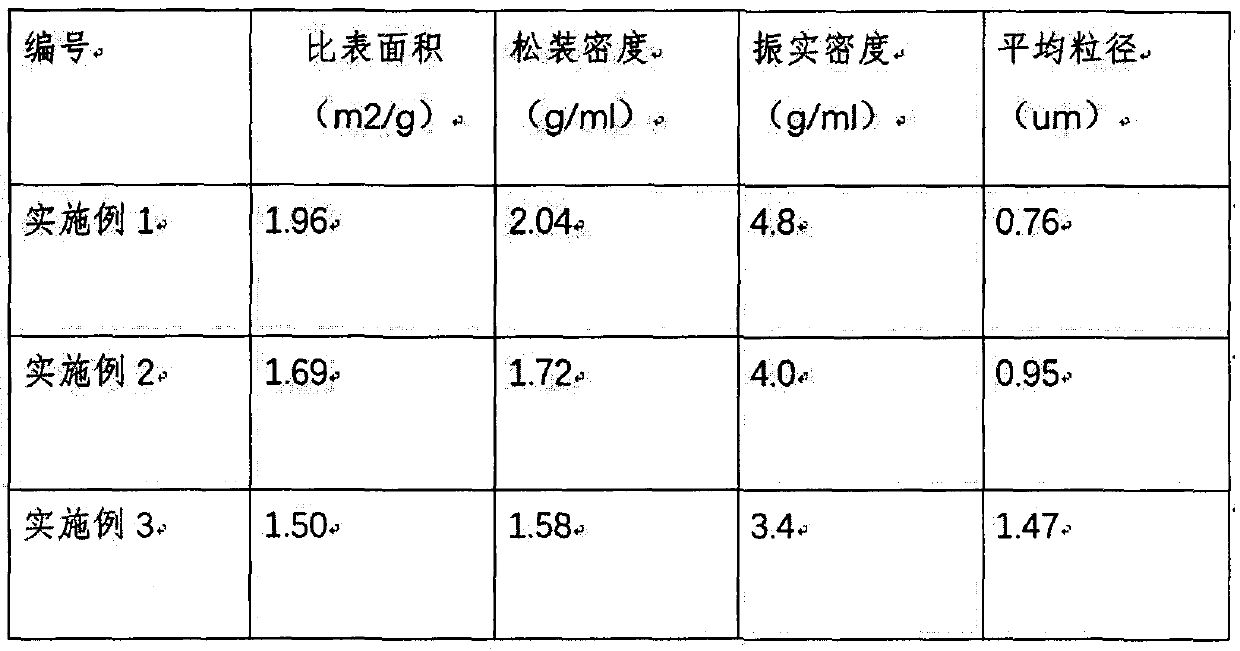

Preparations of nano titanium dioxide particles and titania slurry

The invention relates to a nano titanium dioxide material, in particular to a preparation method of a nano titanium dioxide particle and titanium dioxide slurry. The preparation method of the nano titanium dioxide particle is characterized by including the following steps: a. slowly adding acetic acid with the volume concentration of 5-8mol / L into tetrabutyl titanate with 3-8 times of volume, fully stirring for 15 minutes to 1 hour, then adding the mixture into de-ionized water with 20-30 times of volume, and then adding an alkaline solution to regulate the PH value to be 12-14; and b. putting a precursor mixture prepared in the step a into an autoclave with a polytetrafluoro lining under the condition that the compactness is 45-70 percent, reacting for 10-24 hours at 100-135 DEG C, and washing the reactant with absolute ethyl alcohol and the de-ionized water. The preparation method realizes synthesis and coating in one step by synchronously synthesizing and organically coating the nano titanium dioxide, thereby providing a new method for confecting the titanium dioxide slurry with no agglomeration and delamination and good dispersivity and stability.

Owner:IRICO

Red schorl type titanium dioxide coating method and preparation of used reagent

InactiveCN101463195AHigh whitenessHigh glossPigment treatment with non-polymer organic compoundsAluminateWeather resistance

The invention relates to a rutile type titanium dioxide coating method and a preparation method of reagent used thereby. A layer of ZrO2 is firstly coated on a TiO2 particle, thus improving the white content, lustrousness and weather resistance of the product; four layers of pellumina are coated in batches to further improve the performances such as weather resistance, dispersivity (dry powder fluidness), hiding power, lustrousness and the like of the product; finally, the main function of organic coating is to improve the dry powder fluidness of the product and the dispersivity in the application media; meanwhile, the lustrousness of the product is improved, and the aggregation resistant performance of the product in storage and transportation can be enhanced. Sodium aluminate or aluminium sulphate is added at the different stages of the coating process, so that the pH value the sizing agent can be regulated by utilizing the different pH values of the two aluminates, and the complicated operation that the pH value the sizing agent is regulated after coating agent is added every time is omitted. The titanium dioxide which coated and finally obtained has the advantages of high lustrousness, dispersivity, dry powder fluidness and weather resistance.

Owner:HENGYANG TIANYOU CHEM

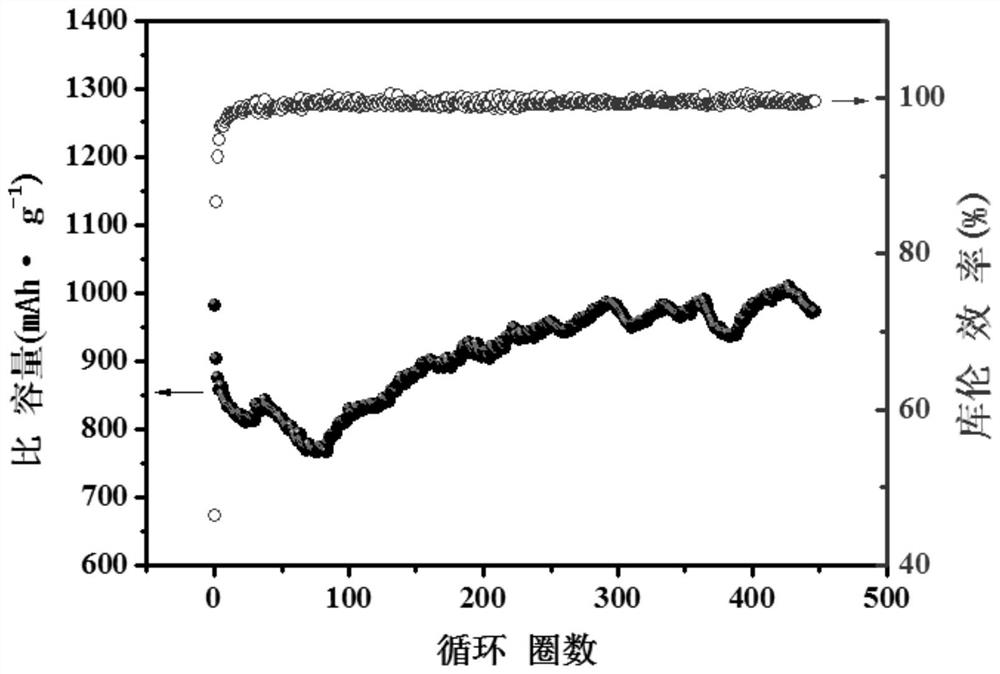

Nanometer lignin carbon-zinc oxidecomposite material as well as preparation method and application thereof

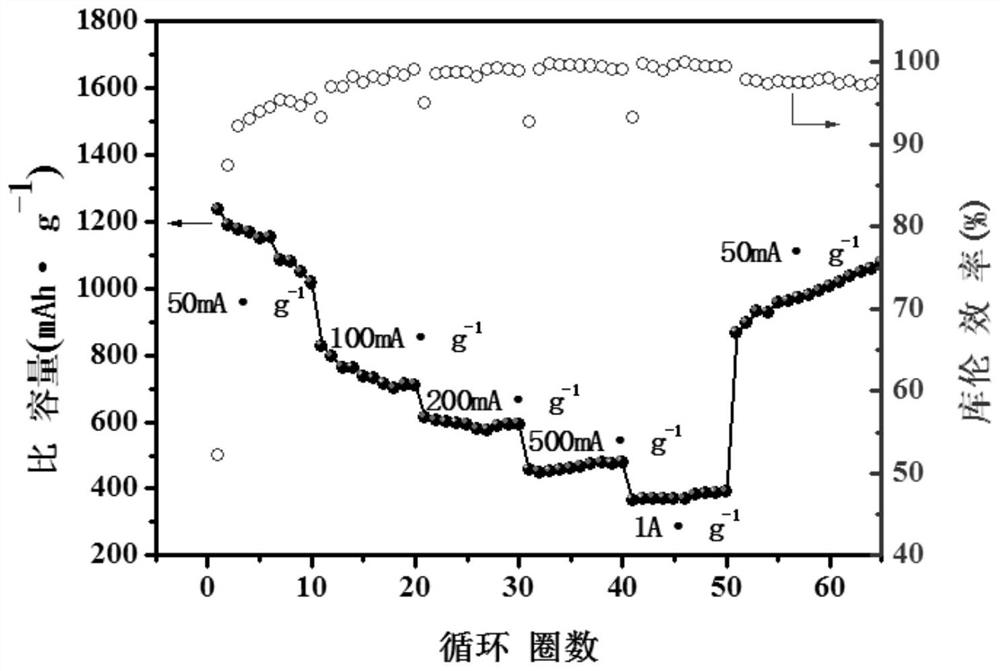

ActiveCN112072085AInhibition of volume expansionImprove conductivityMaterial nanotechnologyHybrid capacitor electrodesCarbon layerLithium-ion battery

The invention discloses a nanometer lignin carbon-zinc oxidecomposite material as well as a preparation method and application thereof. The method comprises the following steps: (1) dissolving ligninin an alkaline solution, carrying out hydrothermal pretreatment, conducting cooling, and adjusting a pH value to 3-5 to obtain an acid-soluble lignin solution; (2) adding a mixed solution of soluble zinc salt and soluble carbonate into the acid-soluble lignin solution, conducting a hydrothermal reaction, then adding aldehydes, and continuing the hydrothermal reaction to obtain a ploycondensed lignin / zinc oxide compound; and (3) carbonizing the polycondensed lignin / zinc oxide compound to obtain the nanometer lignin carbon-zinc oxidecomposite material. In the obtained nanometer lignin carbon-zinc oxidecomposite material, lignin carbon uniformly coats the surfaces of zinc oxide particles to form a uniform carbon layer with a continuous structure, so the problems of serious volume expansion and poor conductivity of zinc oxide serving as a lithium ion negative electrode material are solved, and the specific capacity, the initial coulombic efficiency and the rate capability of a lithium ionbattery are improved.

Owner:SOUTH CHINA UNIV OF TECH +1

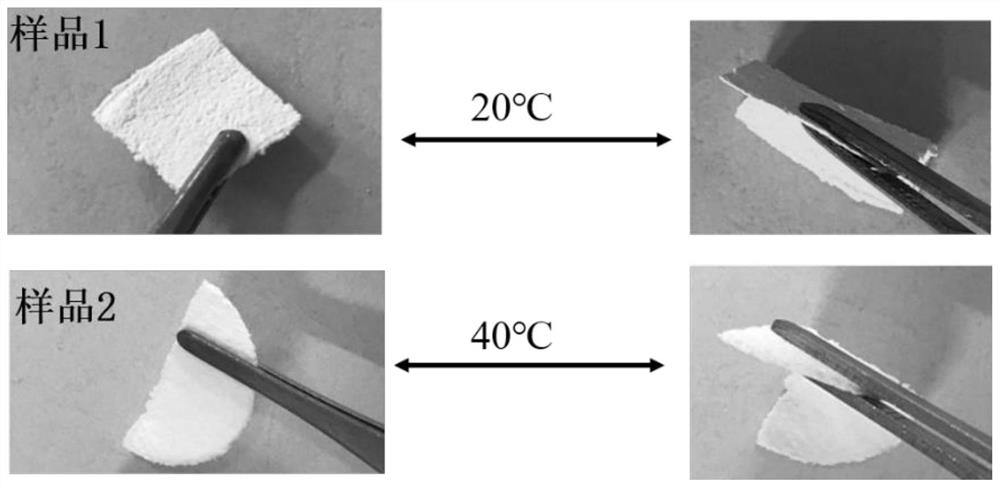

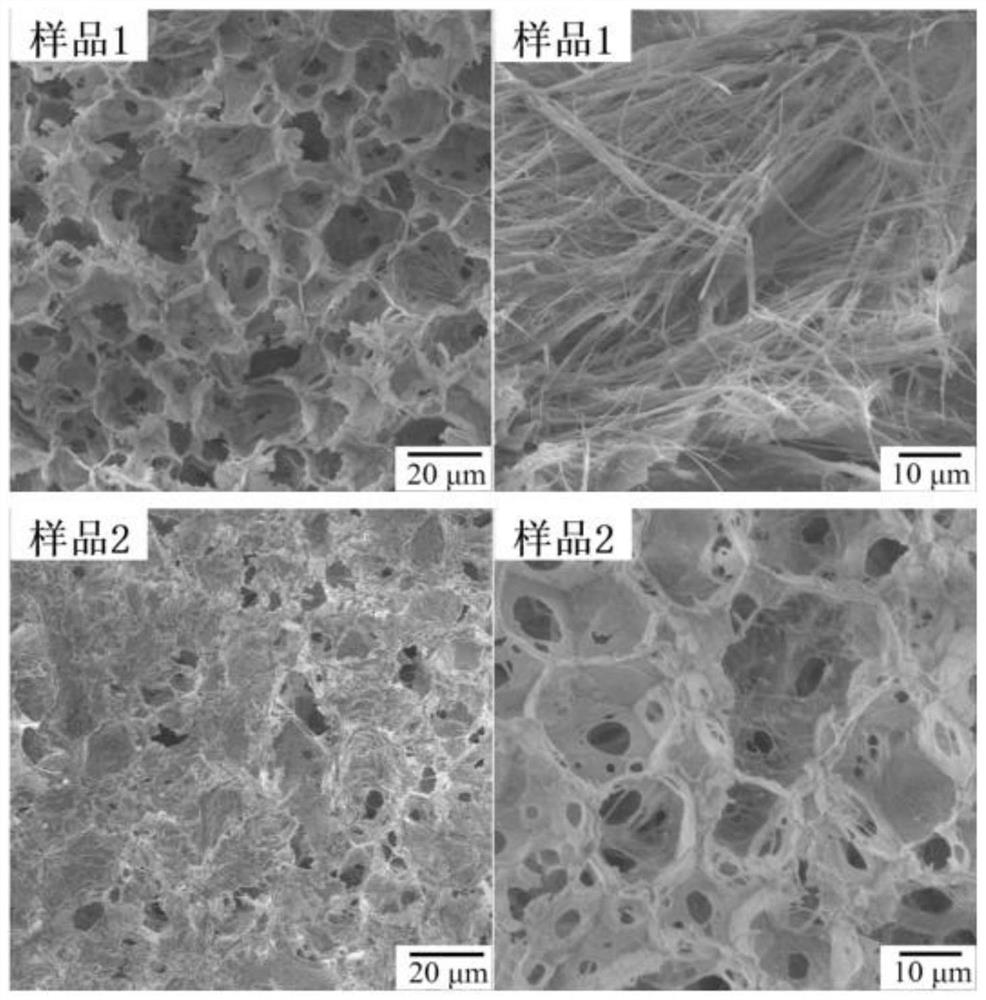

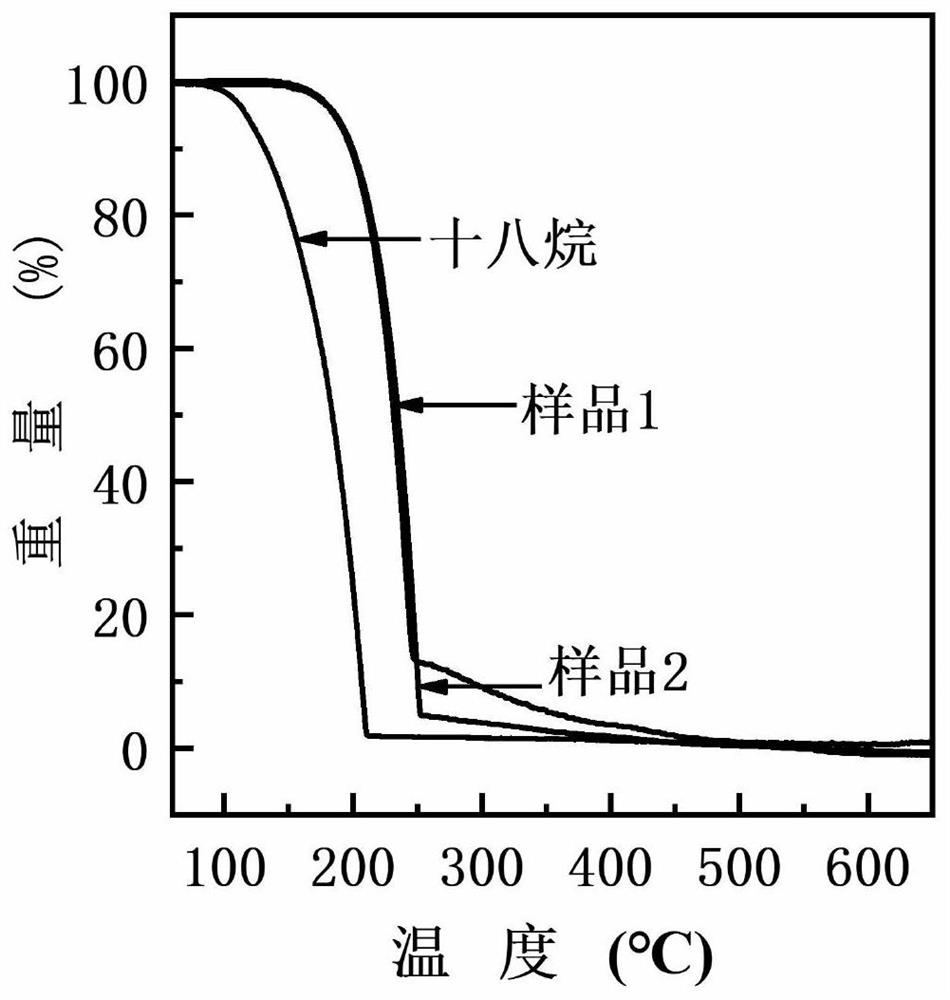

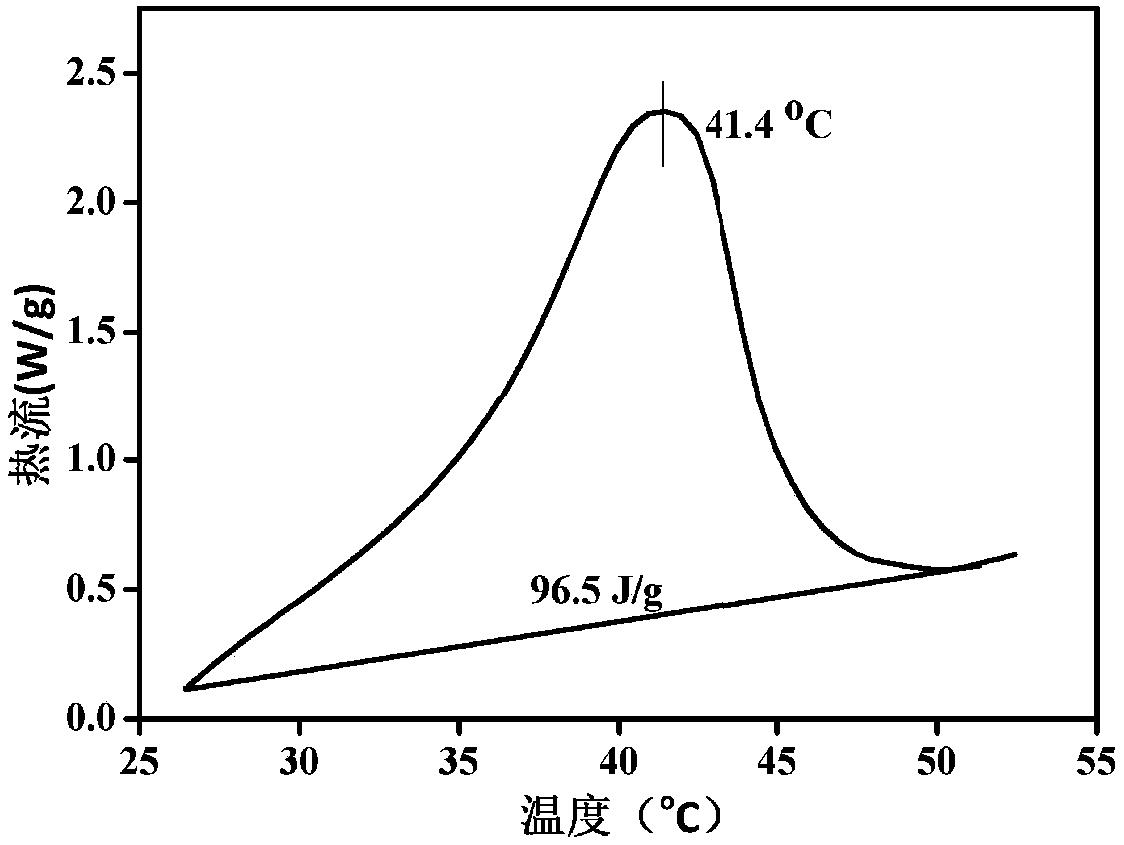

Cellulose-based flexible heat storage composite material and preparation method thereof

ActiveCN113337252AStabilize cross-linking defectsLess cross-linking defectsHeat-exchange elementsCellulosePtru catalyst

The invention provides a cellulose-based flexible heat storage composite material and a preparation method thereof, and the preparation method comprises the following steps: uniformly mixing an oil phase and a water phase to obtain an oil-in-water type high internal phase emulsion, wherein the oil phase is an organic phase change material, the water phase comprises a water-soluble emulsifier, a cellulose suspension and water; adding a cross-linking agent and a catalyst into the oil-in-water type high internal phase emulsion, realizing interfacial polymerization of the cellulose emulsion through heating, forming a cross-linked polymer at an interface, and obtaining the heat storage composite material through heating drying and freeze drying. The appearance of the heat storage composite material can be controlled through a mold for containing the high internal phase emulsion during polymerization, a nanofiber structure is arranged in the heat storage composite material, the heat storage density of the material after heating and drying can reach 200 J / g, the heat storage density of the material after freeze drying can reach 250 J / g, and the heat storage composite material has flexibility, can be curled and folded at the room temperature and the temperature of 40 DEG C or above and is good in heat conduction performance.

Owner:SUZHOU UNIV

Water-based aluminum silver slurry and preparation method thereof, as well as application of water-based aluminum silver slurry in ink

The invention provides water-based aluminum silver slurry and a preparation method thereof, as well as application of the water-based aluminum silver slurry in ink. The preparation method comprises the following steps: (a) mixing oil-based aluminum silver slurry with an alcohol solvent, and carrying out ultrasonic dispersion and solid-liquid separation in sequence to obtain a solid mixture; (b) mixing the solid mixture, the alcohol solvent, a pH value adjuster, a silane coupling agent and tetraethoxysilane, and carrying out reaction, then aging and solid-liquid separation to obtain aluminum-coated silver slurry; (c) drying the aluminum-coated silver slurry to obtain aluminum silver powder; (d) mixing the aluminum silver powder with a solvent, and carrying out solid-liquid separation to obtain the water-based aluminum silver slurry. According to the water-based aluminum silver slurry and the preparation method thereof, the oil-based aluminum silver slurry is washed with the alcohol solvent to wash off fatty acid in the oil-based aluminum silver slurry, so that the oil-based aluminum silver slurry can be better dispersed in the alcohol solvent, and wrapping of aluminum silver slurry is better realized; due to the combination of a drying and solvent mixing treatment method, the obtained water-based aluminum silver slurry is relatively low in volatile organic compound and can meet higher requirements; the application field of the water-based aluminum silver slurry is expanded, and the stability of the water-based aluminum silver slurry is high.

Owner:长沙族兴新材料股份有限公司

Microcapsule guar gum and preparation method thereof

ActiveCN103045212AMicroencapsulationIncrease the use concentrationDrilling compositionHigh concentrationPetroleum resin

The invention provides microcapsule guar gum which comprises guar gum and C5 petroleum resin coating the guar gum. The invention further provides a preparation method of the microcapsule guar gum. According to the embodiment of the application, the guar gum is coated with the C5 petroleum resin, so that the microencapsulation of the guar gum is achieved, a use concentration of the guar gum is increased under the condition that the guarant viscosity is not increased, the microcapsule guar gum with a very high concentration can be pumped over, the gum strength of the guar gum can be improved greatly, and cracks and solution caves of strata can be blocked off well.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Method for producing color-spun and hollow yarns

The invention discloses a method for producing color-spun and hollow yarns, which is novel hollow yarn and color-spun yarn integrated spinning technology. The colored-cotton fibers are subjected to loose stock dyeing, and are coiled by a clear cotton machine, and slivered by a slivering machine; the silvered colored-cotton fibers and the vinylon fibers silvered by carding are folded on a drawing frame, rough yarns are spun by a coarse spinner, and the color-spun and hollow yarns are spun by a spinning frame. In the method, the problem that water-soluble vinylon is heated and shrunk and the strong force of yarns is greatly reduced so as to influence weaving in the process of weaving and starching the hollow yarns is effectively solved.

Owner:SHANDONG DAIYIN TEXTILE GROUP SHARE CO LTD

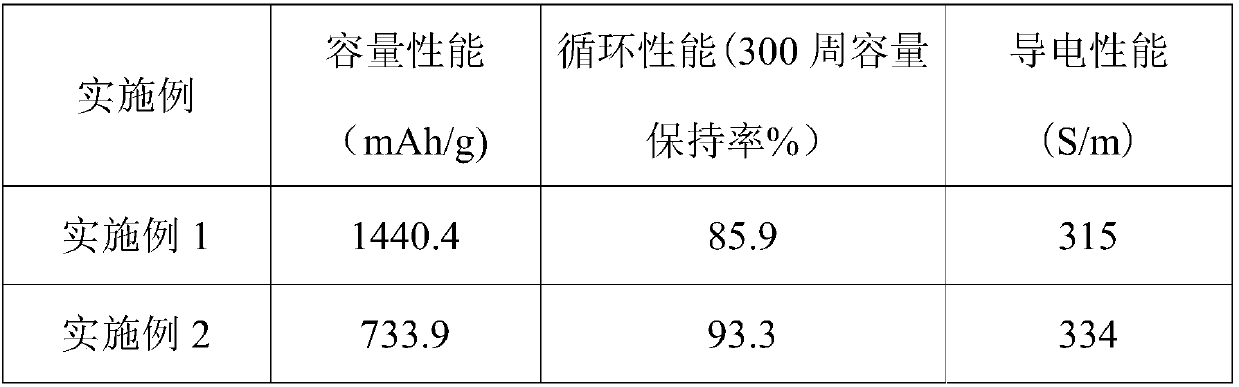

Orderly-arranged silicon-filled carbon nanotube material and preparation method and use thereof

ActiveCN107799751AImprove isolationAvoid consumptionMaterial nanotechnologyCell electrodesCarbon nanotubeSilicon

The invention provides an orderly-arranged silicon-filled carbon nanotube material and a preparation method and a use thereof. The orderly-arranged silicon-filled carbon nanotube material is a material of a core-shell structure; the material of the core-shell structure is formed by filling the carbon nanotube material with a silicon material; the carbon nanotube material is in a carbon nanotube array formed by multiple carbon nanotubes in ordered bunch-shaped arrangement; the two ends of the carbon nanotube material are sealed by carbon; and the carbon nanotube material has the composition ofC<x> / (SiO<y>)<z> / CNT, wherein x is greater than 0.01 and less than or equal to 0.1, y is greater than or equal to 0 and less than or equal to 2, and z is greater than 0 and less than or equal to 1. The orderly-arranged silicon-filled carbon nanotube material provided by the invention has high conductivity, so that a flexible electrode can be prepared conveniently; and when the orderly-arranged silicon-filled carbon nanotube material is applied to the negative electrode of a lithium battery, the interior of the carbon nanotubes is coated with the silicon material, and the silicon material is isolated from an external electrolyte, so that electrolyte consumption caused by constant reaction between the material and the electrolyte can be avoided.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

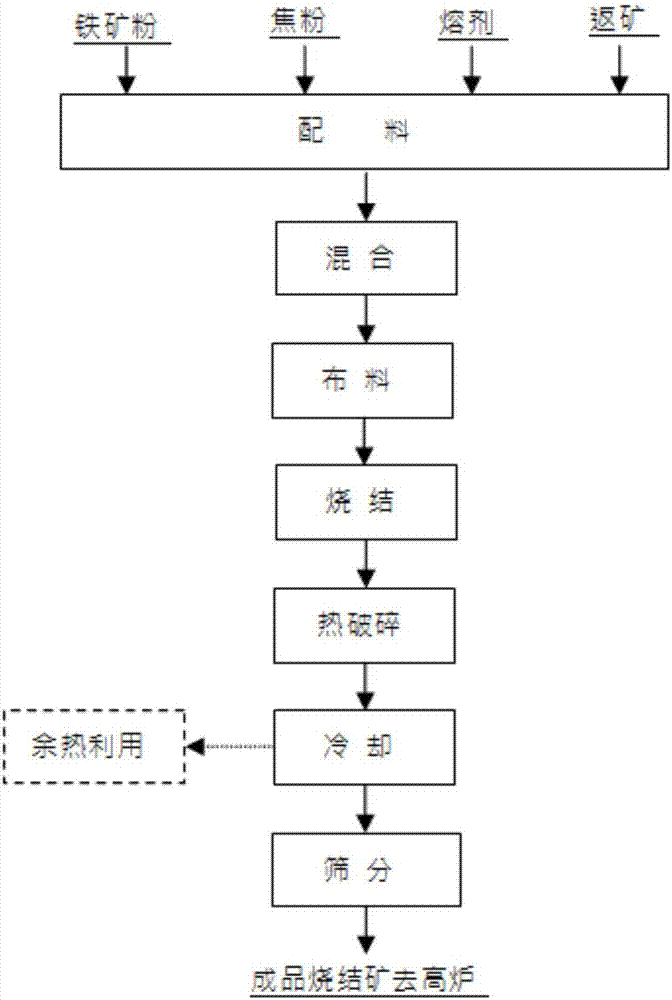

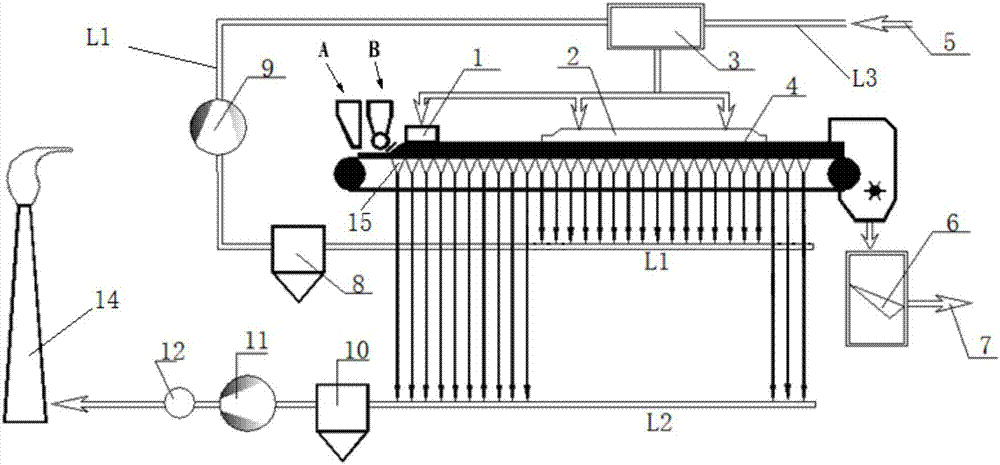

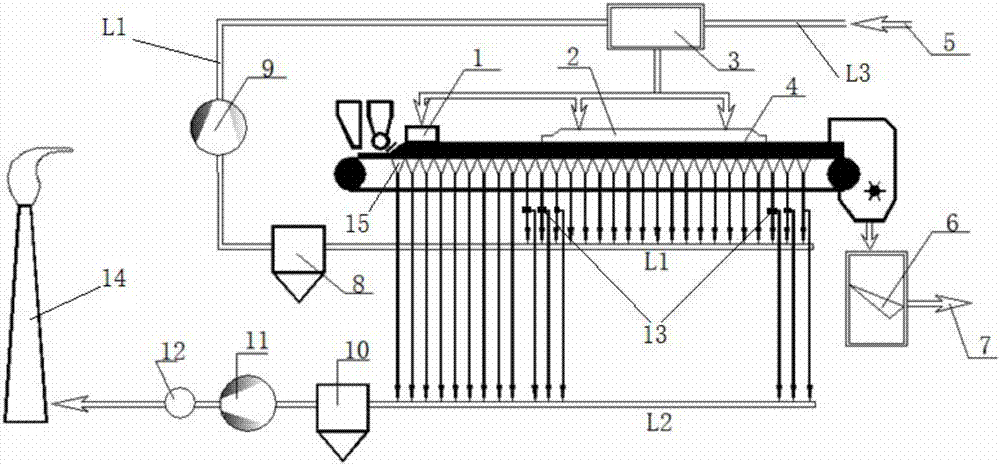

Iron ore pre-reduction sintering method and device

ActiveCN107304460AAchieve recyclingShort processIncreasing energy efficiencyWaste heat treatmentCombustionMaterial distribution

The invention provides an iron ore pre-reduction sintering method. The method comprises the steps that firstly, a traditional mixture is prepared, iron ore powder, a solvent and fuel are subjected to raw material matching, mixing and granulating are conducted, and the traditional mixture is obtained; secondly, a pre-reduction mixture is prepared, after the iron ore powder, an additive and the fuel are evenly mixed, pelleting is conducted, carbon-burdened pellets are obtained and placed in a cylinder mixer, fuel fine powder and quick lime or slaked lime are added for wrapping and granulating, and the pre-reduction mixture is obtained; thirdly, material distribution is conducted, a double-layer material distribution manner is adopted, the pre-reduction mixer prepared in the second step is placed on a sintering machine trolley in advance, and the traditional mixture prepared in the first step is placed on the pre-reduction mixture; and fourthly, sintering is conducted, ignition is conducted, and the traditional mixture and the pre-reduction mixture are subjected to smoke circulation type sintering on a sintering machine. The problem that CO smoke is hard to treat is solved, secondary oxidization in the pre-reduction sinter reducing process is reduced, the combustion atmosphere between material layers is improved, the material temperature is increased, and generation of the iron ore material reducing reaction is accelerated.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

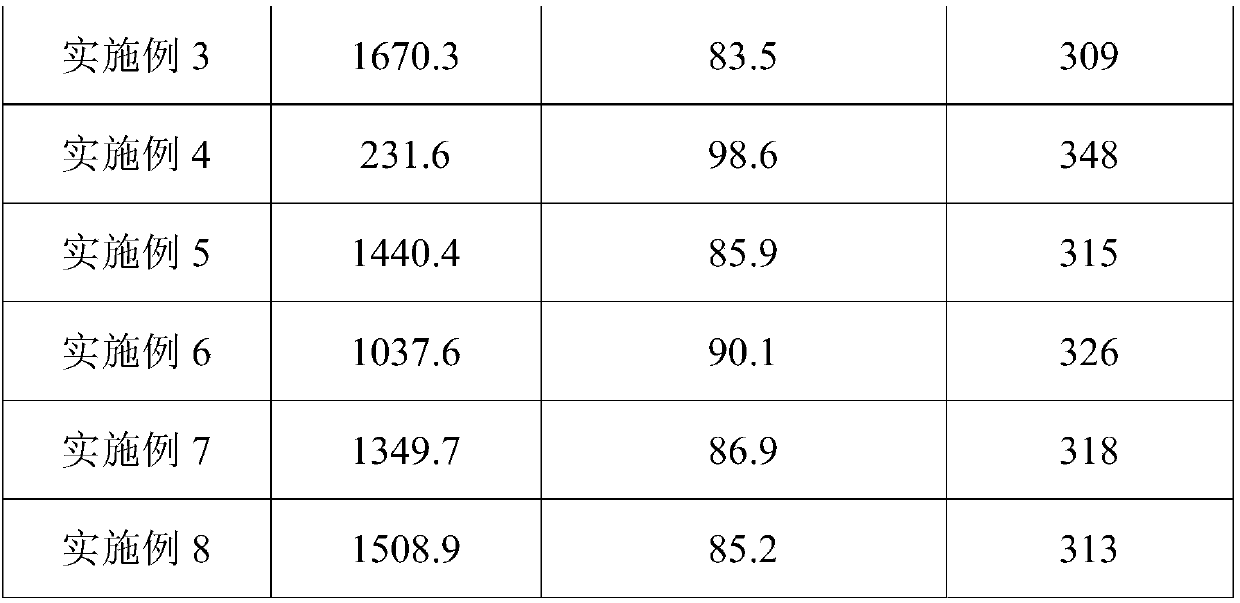

Negative electrode material with high temperature resistance, preparation method of negative electrode material and application of negative electrode material in lithium-ion battery

ActiveCN107919472AUniform coatingAchieve coatingSecondary cellsNegative electrodesHigh temperature storageCarbon coating

The invention discloses a negative electrode material with high temperature resistance, a preparation method of the negative electrode material and an application of the negative electrode material ina lithium-ion battery. The negative electrode material comprises soft carbon and / or hard carbon powder particles as a core, a carbon coating and a nano coating, wherein the carbon coating and the nano coating sequentially coat the surface of the core from inside to outside; and the carbon coating is transformed from a multifunctional group polymer material. The method comprises the steps of (1) preparing a material formed by coating soft carbon and / or hard carbon with the multifunctional group polymer material; (2) forming a nano material coating on the surface of the material; and (3) and burning to obtain the negative electrode material. The method disclosed by the invention is simple and feasible in process and low in manufacturing cost, and massive production can be implemented; and the prepared negative electrode material has very excellent electrochemical properties, especially high-temperature cycle performance and high-temperature storage performance, the capacity retention ratio after 50 charge-discharge cycles at high temperature of 45 DEG C and 1C can reach 93.3%, and the capacity retention ratio after discharge at room temperature and 0.1C can reach 98.3%.

Owner:深圳贝特瑞钠电新材料科技有限公司

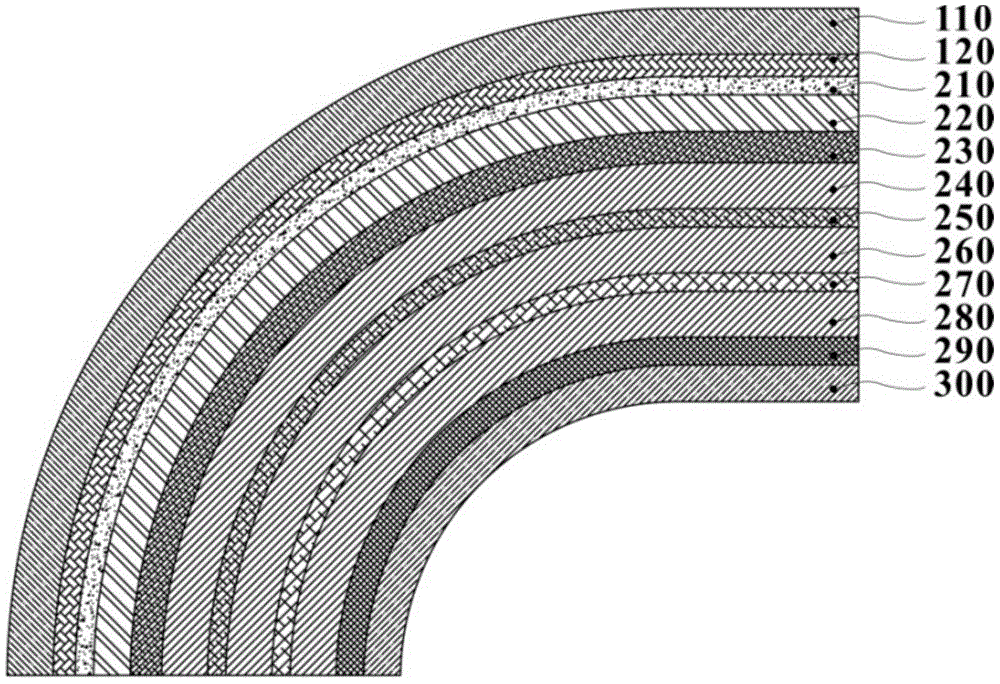

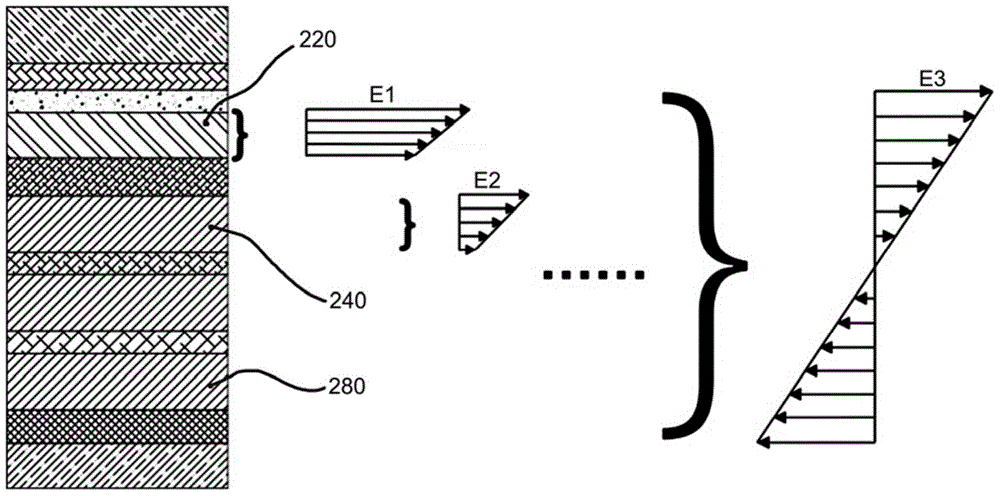

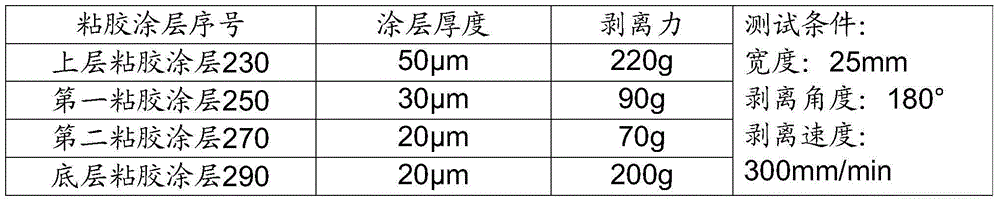

A multi-layer elastic composite film having functions of bending shape maintenance and impact resistance and a preparing method thereof

ActiveCN104608445AOvercoming bending elasticityOvercome elasticitySynthetic resin layered productsLaminationComposite filmAdhesive

The invention discloses a multi-layer elastic composite film having functions of bending shape maintenance and impact resistance and a preparing method thereof. The composite film has a function of cambered surface covering shape maintenance, a function of elastic vibration absorption and a function of resisting violent impact. The composite film comprises a film protecting layer, a using layer and a stripping layer from top to bottom. The film protecting layer is disposed on the using layer. The stripping layer is disposed under the using layer. The using layer comprises a UV coating, an uppermost transparent film, an upper adhesive coating, a first soft transparent film, a first adhesive coating, a second soft transparent film, a second adhesive coating, and a lowest soft transparent film from top to bottom. The composite film can be firmly adhered to a screen, is not liable to rebound, and has good cambered surface fitting and shape maintenance capability, thus achieving cambered surface edge covering.

Owner:NALI OPTICAL MATERIAL DONGGUAN

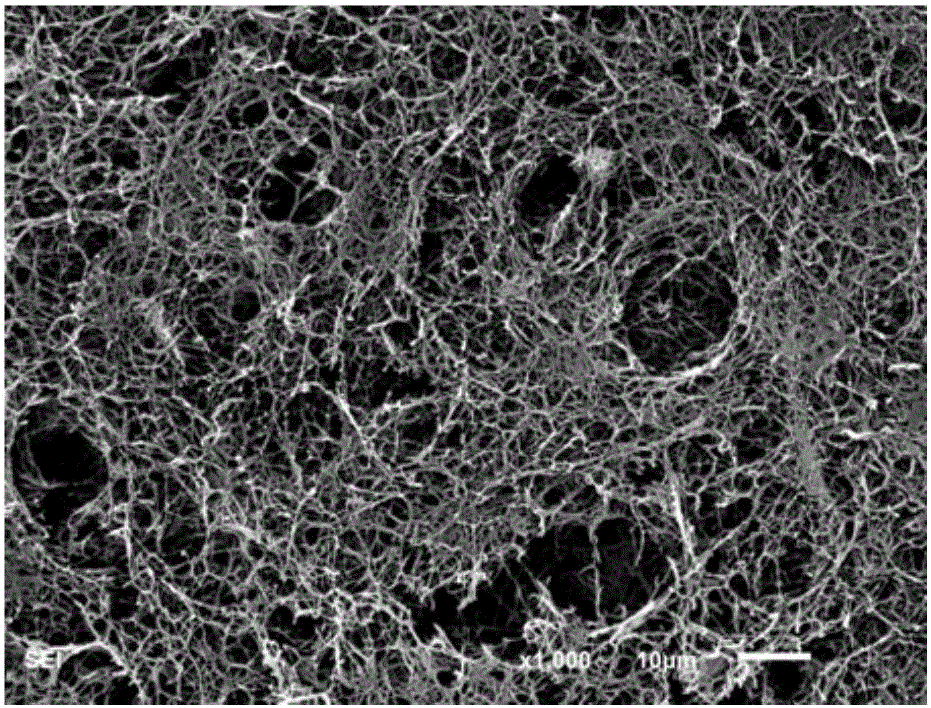

Preparation method of nanofiber aerogel material with hard magnetism

ActiveCN106334538AImprove mechanical propertiesGood biocompatibilityOther chemical processesAlkali metal oxides/hydroxidesFiberAir filtration

The invention discloses a preparation method of a nanofiber aerogel material with hard magnetism, and belongs to the field of nanofiber functional materials. The preparation method comprises the following steps: 1) preparing demagnetized composite particles; 2) blending the demagnetized composite material and cellulose acetate butyrate, performing melting extrusion and extracting to prepare composite nanofiber; 3) dissolving the composite nanofiber by using a solvent, mixing with a bonding agent, freezing and drying to prepare a composite nanofiber aerogel; 4) magnetizing the composite nanofiber aerogel. The preparation method is simple in process and pollution-free, and is suitable for industrial production; the prepared hard-magnetism aerogel has the advantages of superparamagnetism and relatively high strength, has the characteristics of a high specific surface area, high porosity, low heat conductivity and the like, and can be widely applied to the fields of air filtration, electromagnetic shielding, energy absorption and the like.

Owner:WUHAN TEXTILE UNIV +1

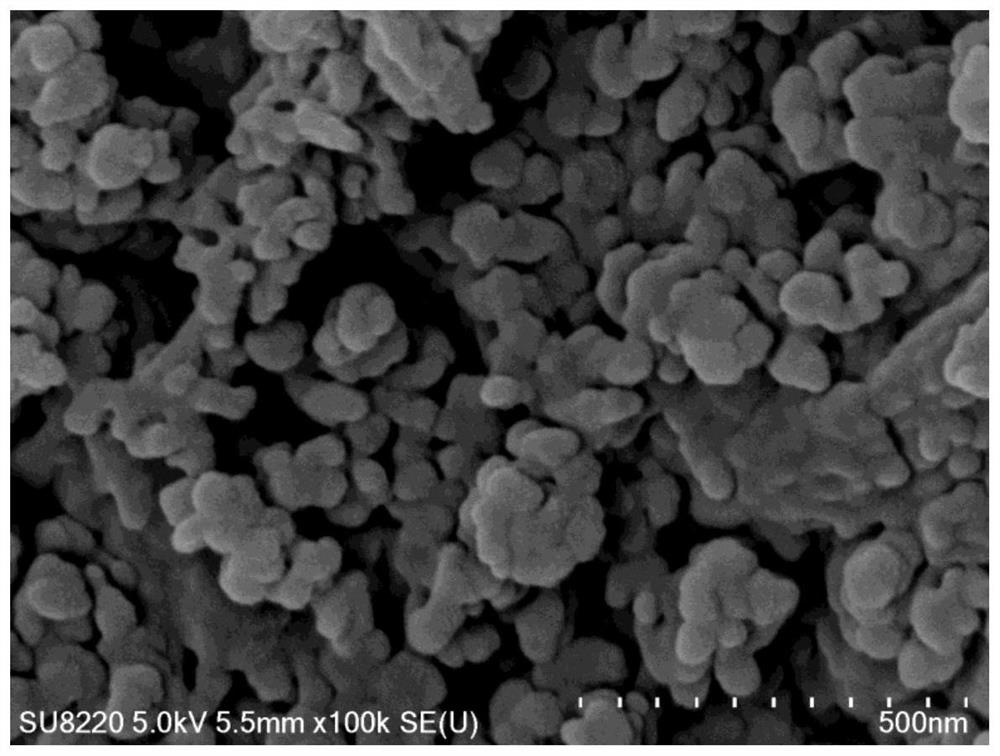

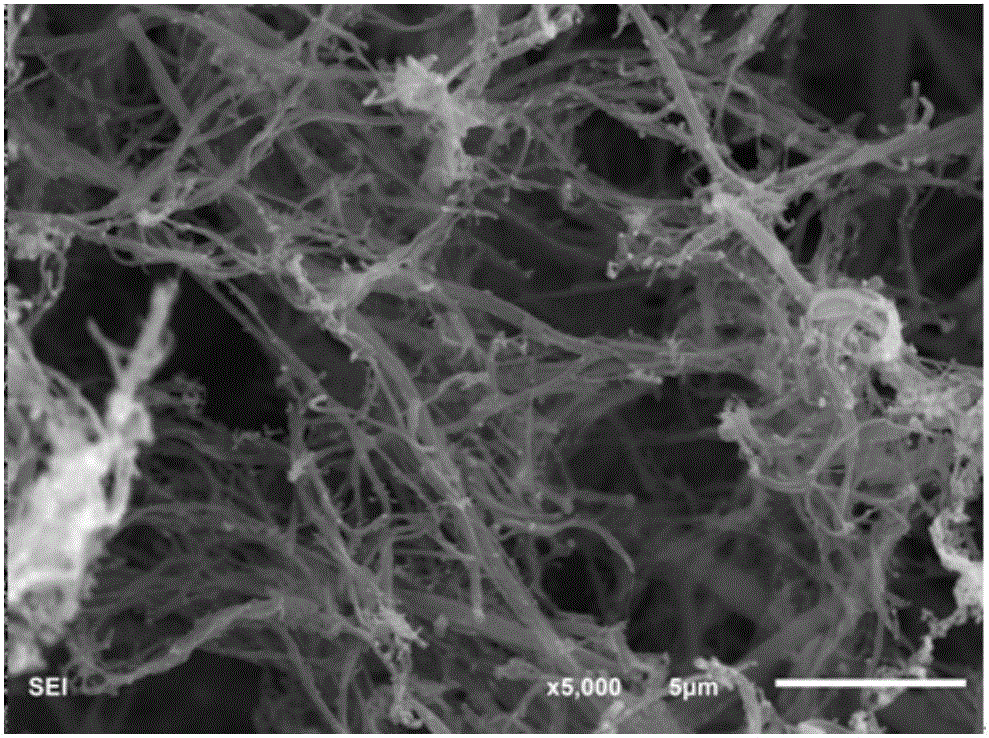

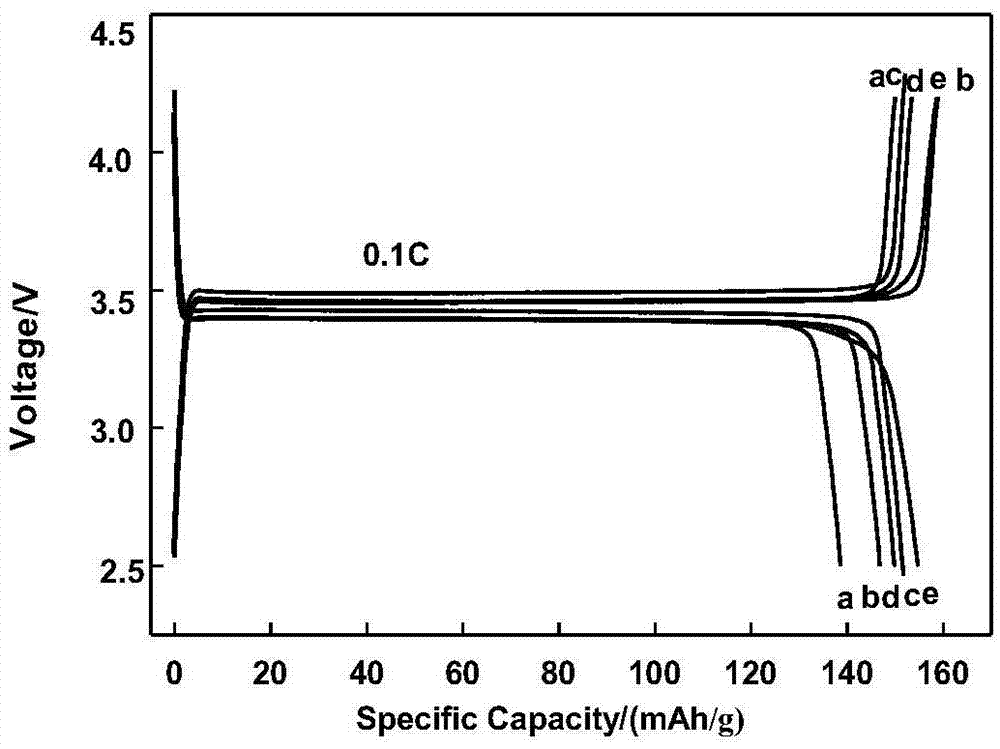

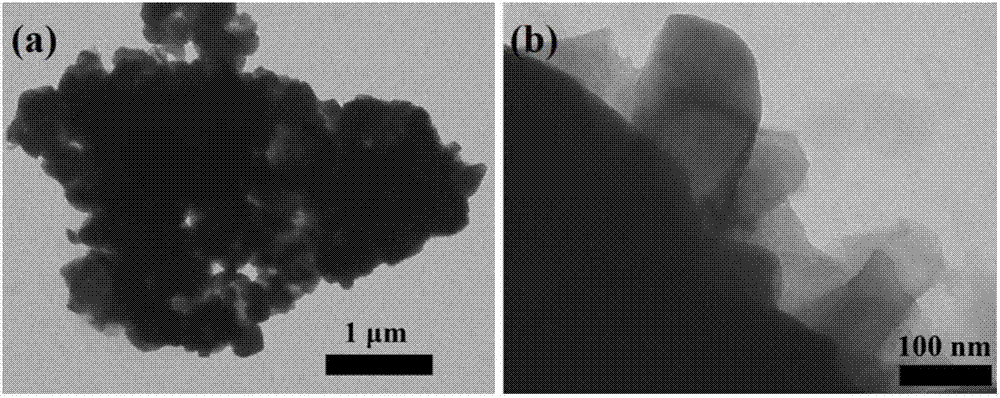

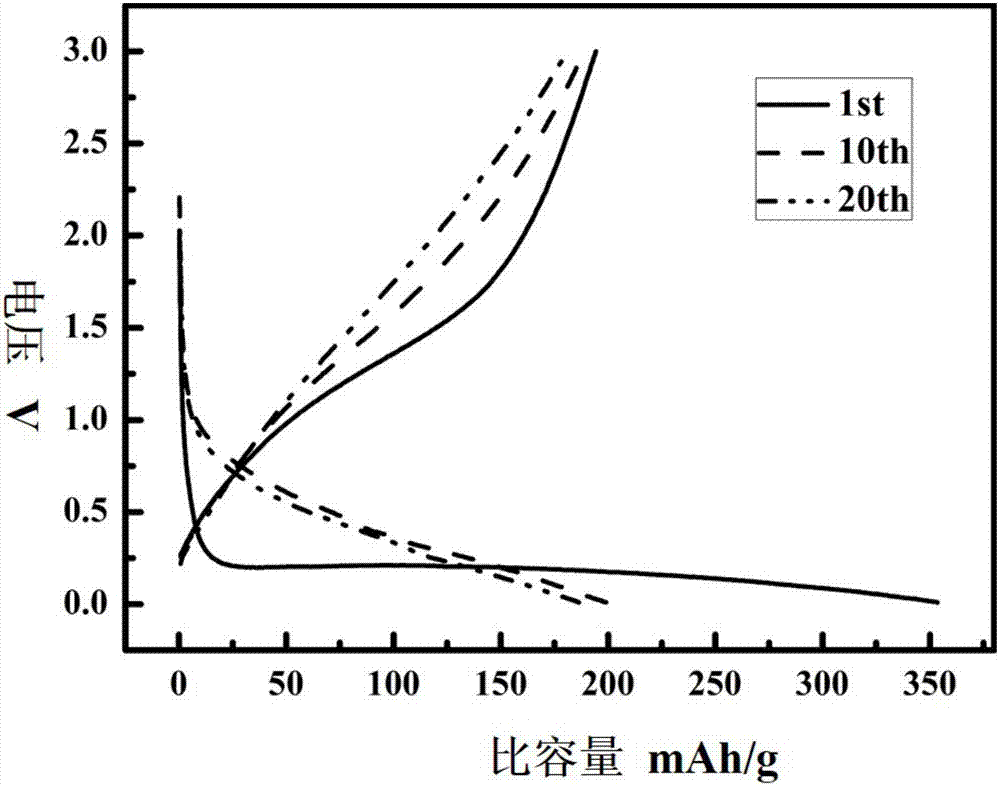

Spherical micro-nano ferric phosphate/carbon composite material and preparation method thereof

ActiveCN105449208AHas a spherical structureAchieve wrappingCell electrodesSecondary cellsPhosphateCarbon composites

The invention discloses a spherical micro-nano ferric phosphate / carbon composite material and a preparation method thereof. The preparation method comprises the following steps: (1) preparing aqueous solution of ferric salt and a phosphorous compound, wherein the mole ratio of the ferric element to the phosphorus element is (0.9-1.2): 1, and the solution concentration is 0.2-5 mol / L; (2) dispersing a high polymer material binder in the solution in the step (1), wherein the dosage of the high polymer material binder is 0.5-90 wt / % of the ferric salt; (3) adding the solution prepared in the step (2) into a reaction still, continuously adding alkali solution to ensure that the pH in the reaction still is kept in 2-4, and reacting at a temperature of 20-90DEG C for 1-60 hours to obtain a crystal water-containing spherical micro-nano ferric phosphate / carbon composite material; and (4) under an inert atmosphere, roasting the spherical micro-nano ferric phosphate / carbon composite material prepared in the step (3) at a temperature of 300-800DEG C for 3-12 hours, and cooling to obtain the product. According to the preparation method, the coating of carbon materials is realized, and a crucial role is played in subsequently preparing high-density high-performance lithium ion battery LiFePO4 anode materials.

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI

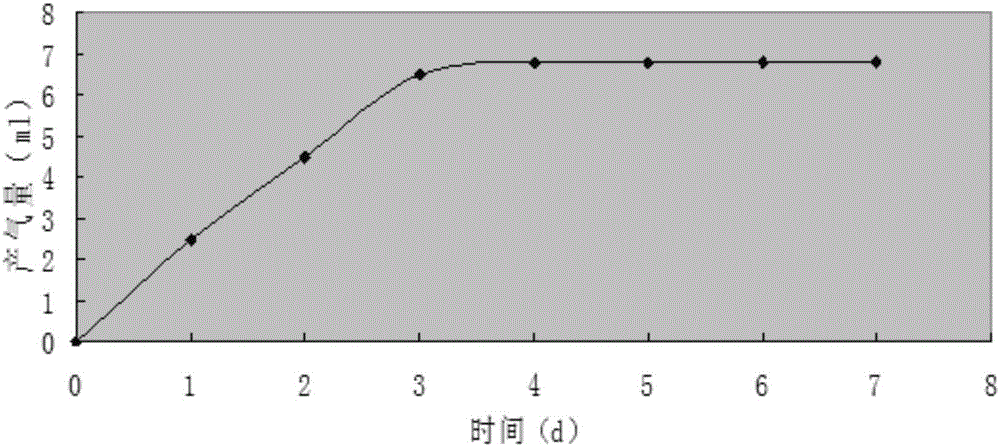

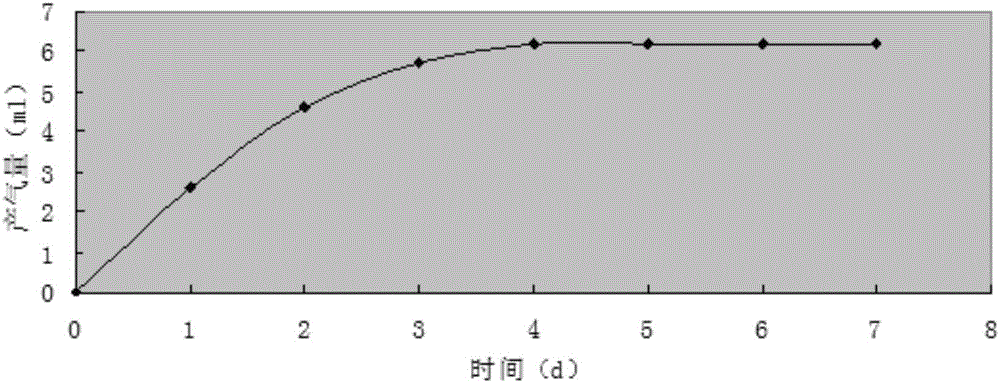

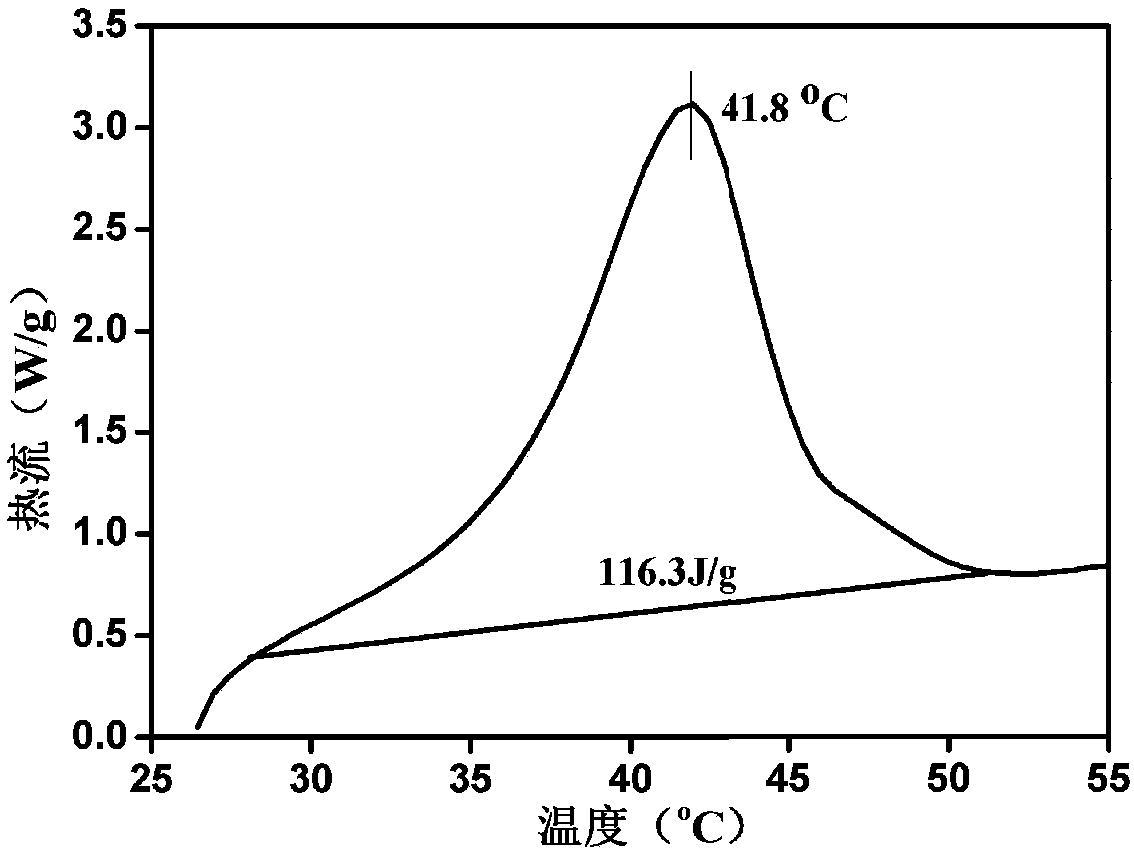

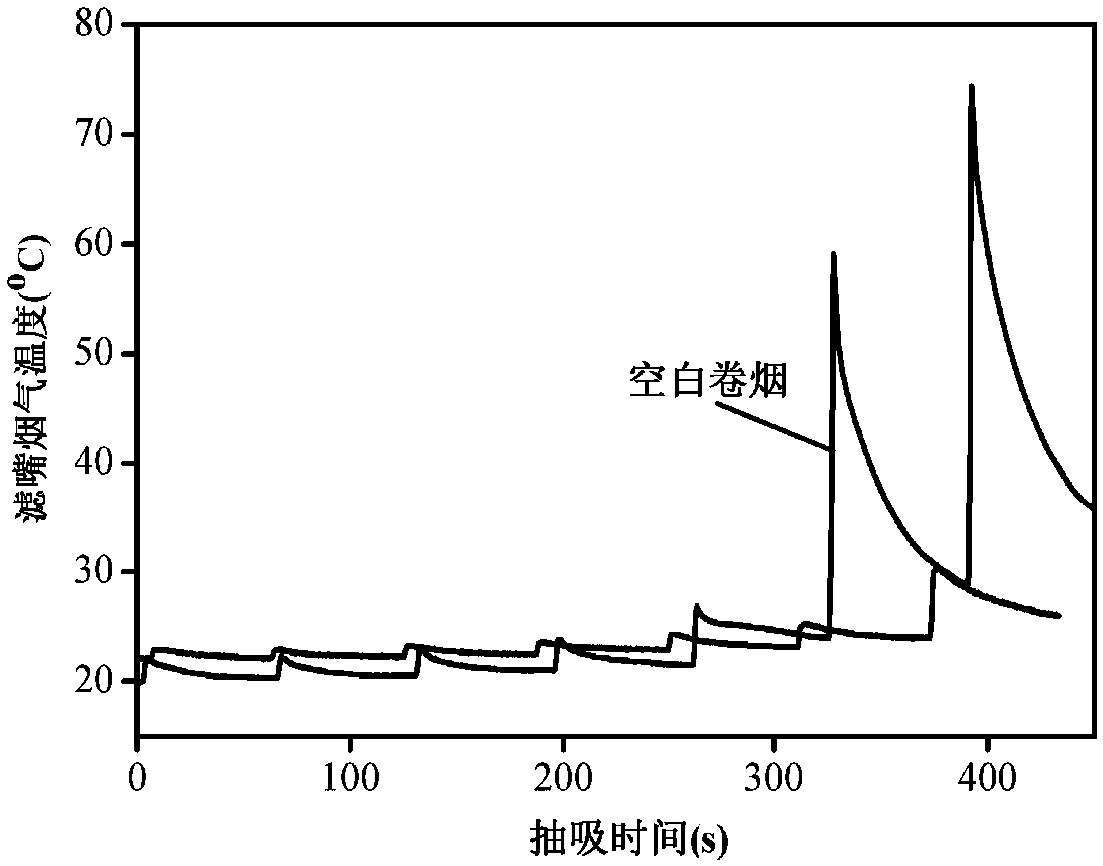

Heat accumulation capsule for decreasing temperature of main stream smoke of cigarettes as well as preparation method and application of heat accumulation capsule

ActiveCN109674085AAchieve wrappingSimple stepsTobacco smoke filtersHeat-exchange elementsChemical reactionElectrospinning

The invention discloses a heat accumulation capsule for decreasing the temperature of main stream smoke of cigarettes. The heat accumulation capsule comprises a wall material and a core material, wherein the core material contains an inorganic phase-change material; and the wall material is polylactic acid; and the inorganic phase-change material is disodium hydrogen phosphate dodecahydrate. The invention further discloses a preparation method of the heat accumulation capsule. The preparation method comprises the steps of simultaneously dropwise adding a core material solution and a wall material solution into concretion liquid respectively through inner holes of an electrostatic spinning coaxial needle head and gaps between inner and outer holes of the electrostatic spinning coaxial needle head, stirring, and carrying out solid-liquid separation, washing, cooling and concretion. The preparation method is different from existing commonly adopted chemical methods, and the inorganic phase-change material is coated by virtue of a physical method. Compared with the chemical methods, the preparation method has the advantages that the complicated chemical reaction steps are reduced, theovermuch chemical solvent is not used, a device is simple, and the particle size of the heat accumulation capsule is controllable.

Owner:CHINA TOBACCO HUNAN INDAL CORP

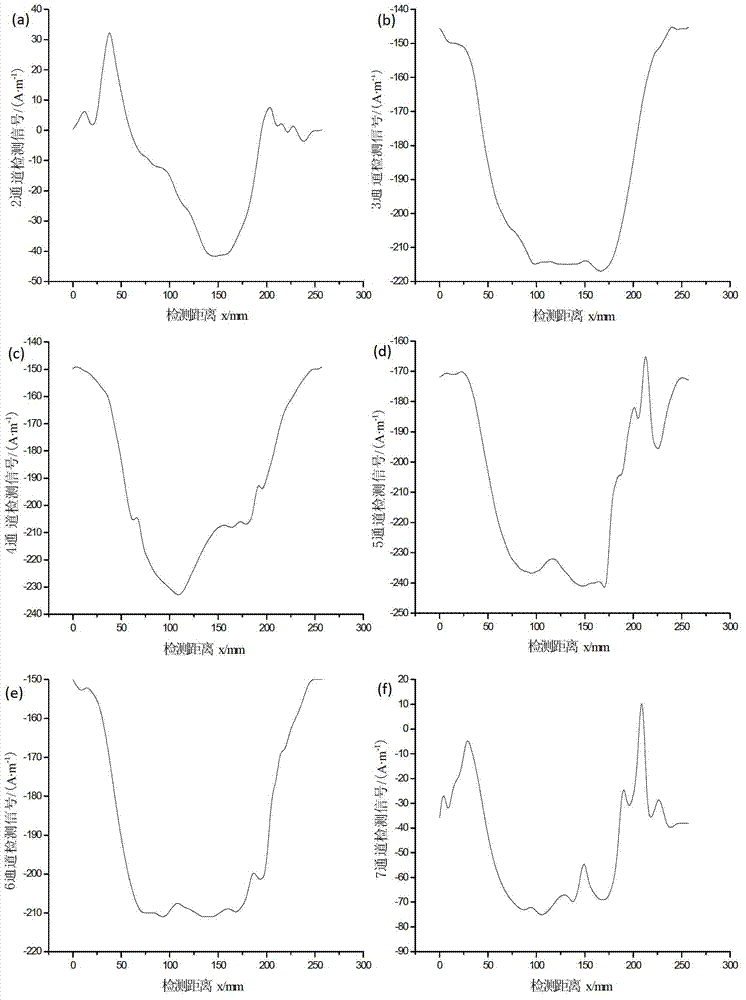

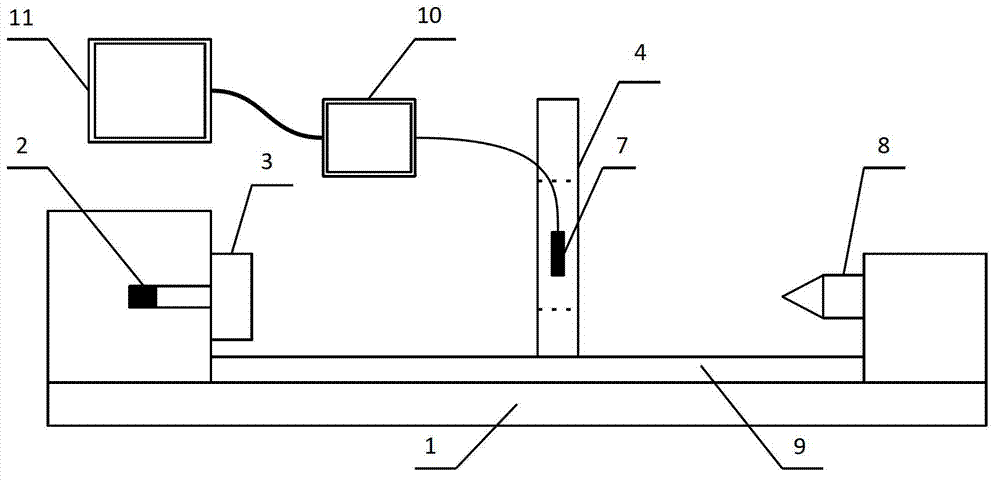

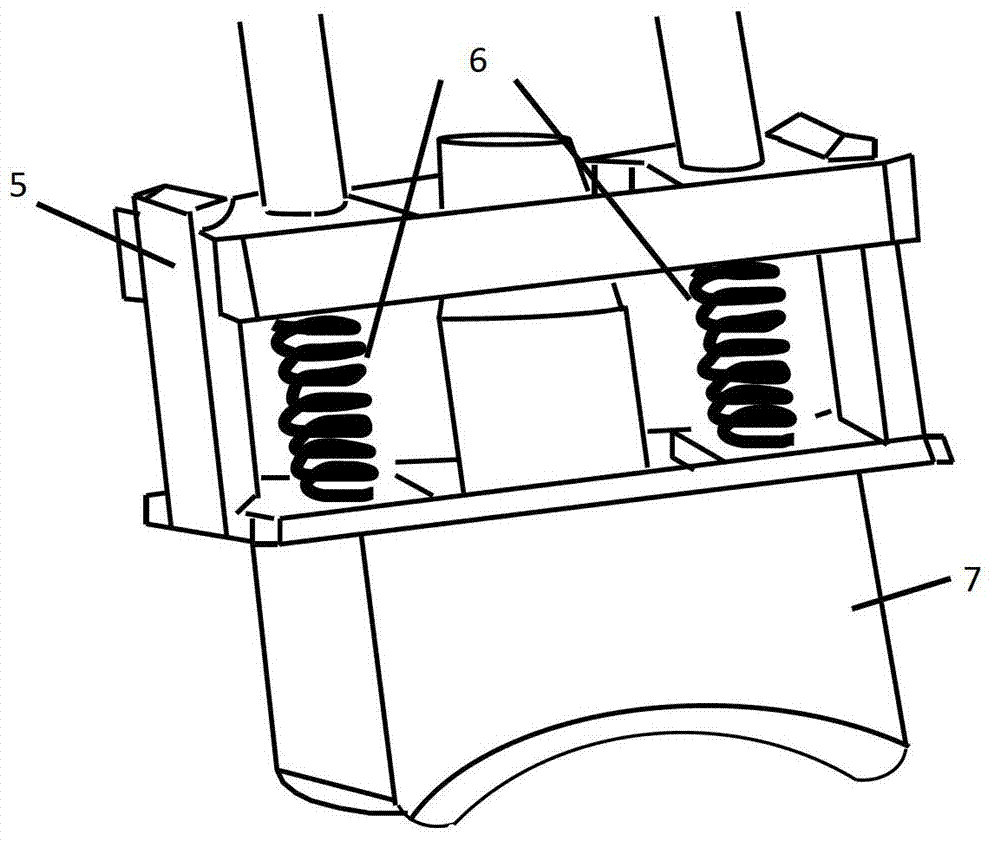

System for automatically detecting and evaluating early fatigue damage of remanufactured front crankshaft

InactiveCN102879459AAvoid missing detectionHigh degree of automationMaterial magnetic variablesNondestructive testingEngineering

The invention discloses a system for automatically detecting and evaluating early fatigue damage of a remanufactured front crankshaft and belongs to the field of nondestructive testing. According to the system, a probe is arranged in a probe clamp; a detection probe is driven by a portal frame to move over a journal of a connecting rod to be detected, the phase is adjusted to be consistent with the journal of the connecting rod to be detected, and the detection probe is tightly attached to the surface of the journal of the connecting rod; the crankshaft rotates at a constant speed around a center line of a main journal, the journal of the connecting rod eccentrically rotates, the detection probe follows up and rotates at a constant speed round the circumference of the journal of the connecting rod, and a signal acquisition instrument begins to acquire signals; after rotating a circle, the crankshaft is automatically stopped, the signal acquisition instrument stops acquiring signals and uploads the signals; and an industrial personal computer analyzes the data of the signals and gives the fatigue damage degree of the journal of the connecting rod and can save the detection signal. By the system, a complex shape at an R angle of the journal of the connecting rod of the crankshaft can be matched, three damage signals in potential directions at the R angle on two sides of the journal of the connecting rod where fatigue easily occurs can be acquired at the constant speed, and the damage signals of the journal of each connecting rod of the whole crankshaft can be detected.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

Preparation method of special solid polishing agent for stainless steel product

The invention discloses a preparation method of a special solid polishing agent for a stainless steel product, and belongs to the technical field of metal processing aids. The method comprises the following steps that the coated modified aluminum oxide and absolute ethyl alcohol are mixed firstly and then undergo ultrasonic dispersion, then the treatment is carried out by using polyvinylpyrrolidone, the coated modified aluminum oxide dispersion liquid is prepared, then the coated modified aluminum oxide dispersion liquid and the monomer acrylamide are mixed, under the action of a cross-linkingagent and an initiator, the monomer is polymerized to form the three-dimensional size network gel, then the dopamine is used for assistant, after the reaction is finished, vacuum drying is carried out, the dry gel is prepared, then the dry stearic acid, the linoleic acid, the citric acid and the oxalic acid are mixed, then heating and melting are carried out, then the dry gel is added, after stirring and mixing are achieved, injection molding, cooling and forming, and demolding are carried out, and the special solid polishing agent for the stainless steel product is obtained. According to thepreparation method, the prepared special solid polishing agent for the stainless steel product has an excellent polishing effect, and the glossiness is effectively improved.

Owner:吴伟华

Preparation method of ultraviolet screening agent

InactiveCN107090200AImprove screening effectAchieve wrappingRadiation-absorbing paintsUltraviolet lightsCalcination

The invention relates to a preparation method of an ultraviolet screening agent, and belongs to the technical field of inorganic nanometer composite materials. The preparation method comprises the steps that tetrabutyl titanate and ethanol solution are mixed and heated, and after the pH value is adjusted by an acetate solution, aging is conducted to obtain a mixed sol; the mixed sol is subjected to calcination, ball grinding and sieving, and nanometer titanium dioxide powder is obtained; raw materials, such as tetrapropylammonium hydroxide and deionized water, are mixed and heated and subjected to centrifugalization, and lower-layered precipitates are collected, then washed and dried, and mixed and subjected to ball grinding with indium tin oxide; the ball-grinding powder and absolute ethyl alcohol are mixed and dispersed, and a modified dispersion liquid is obtained; the modified dispersion liquid and the prepared nanometer titanium dioxide powder are mixed, heated and filtered, a filter cake is subjected to drying, calcination, grinding and sieving, and the product is obtained. The prepared ultraviolet screening agent can absorb ultraviolet light effectively and lowers photocatalytic activity greatly, and the ultraviolet screening rate can reach 96.5% or above.

Owner:周益铭

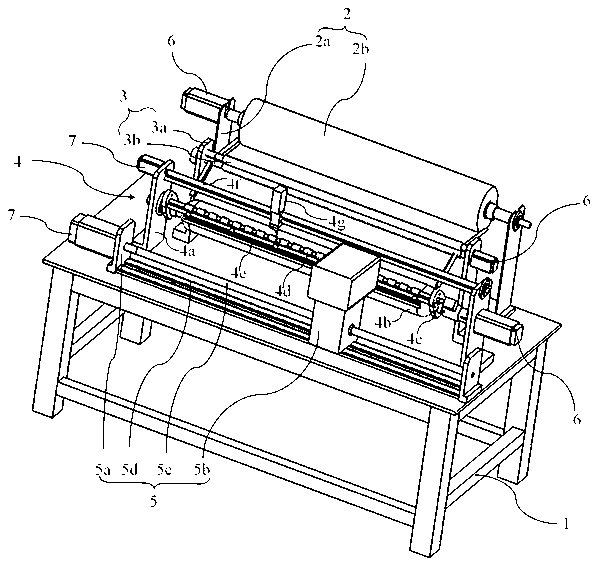

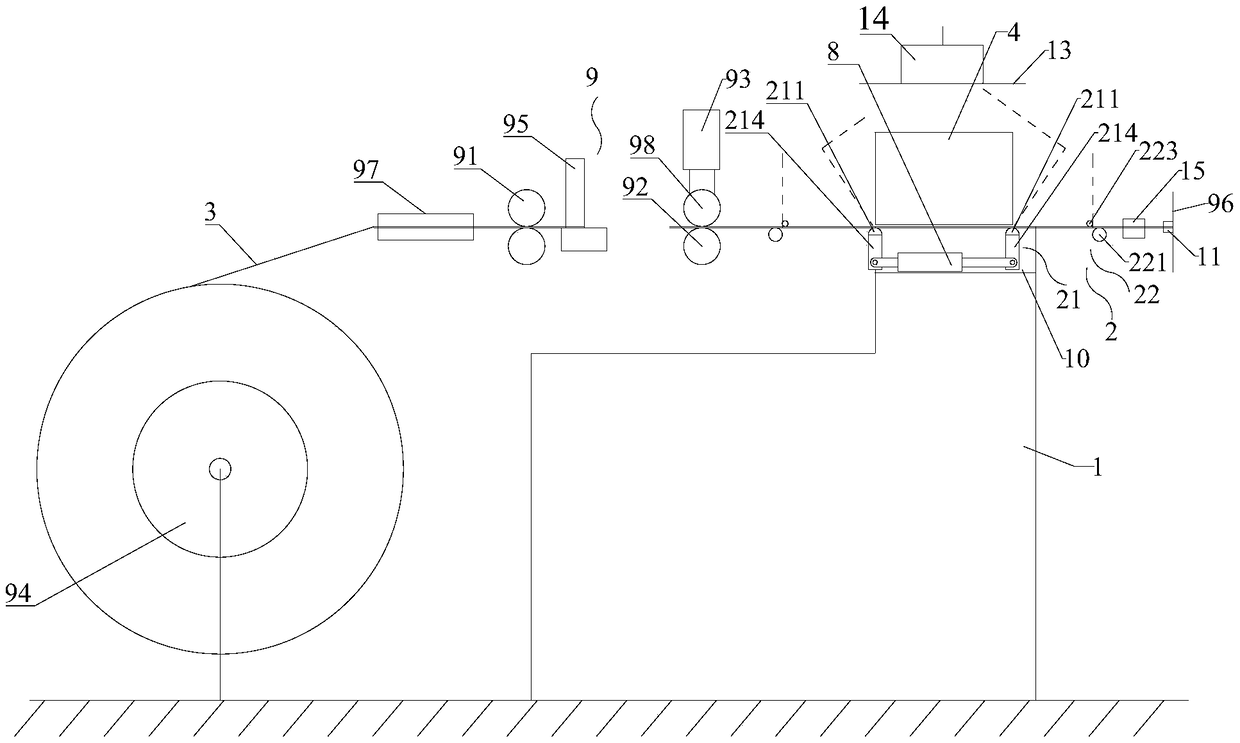

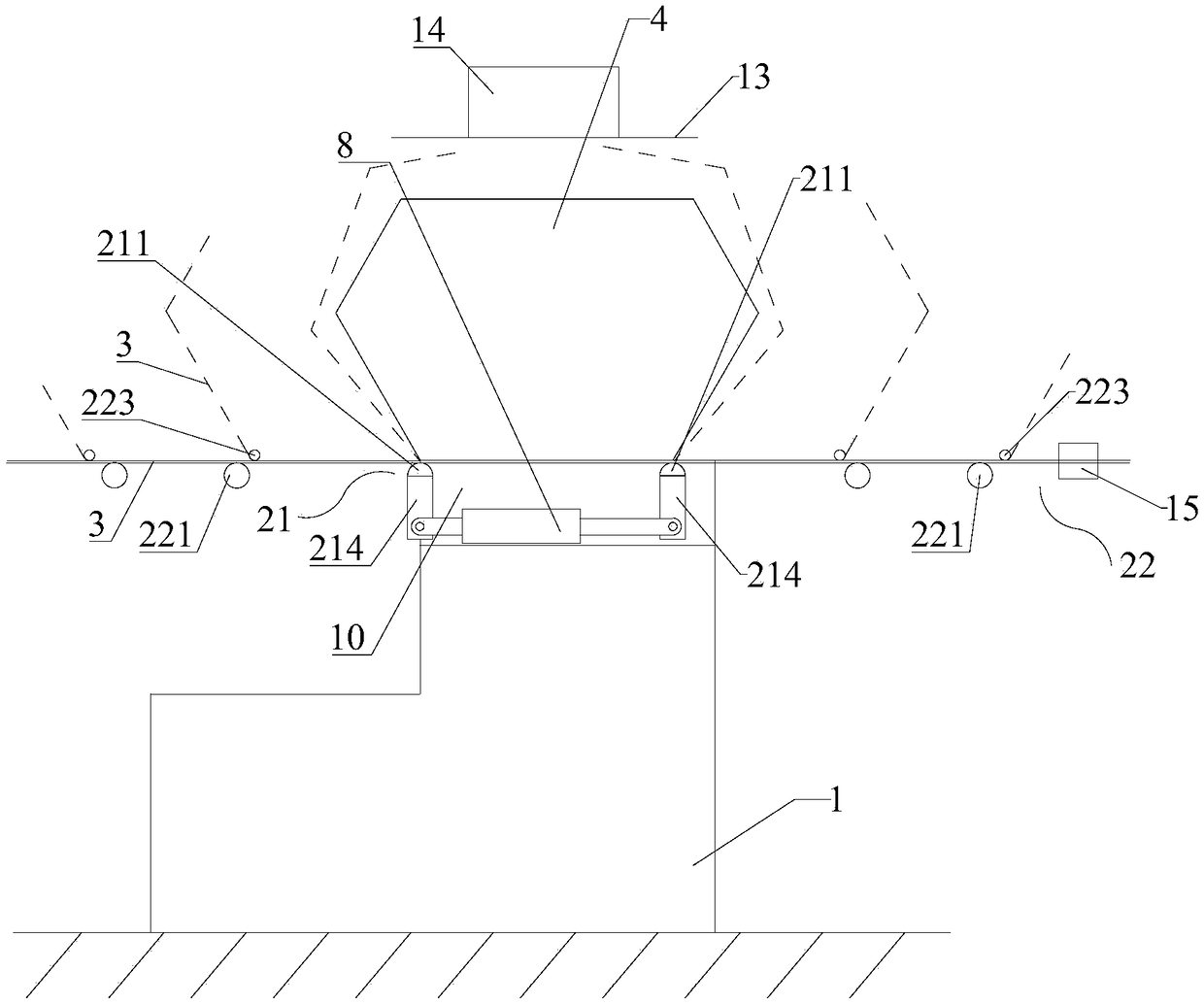

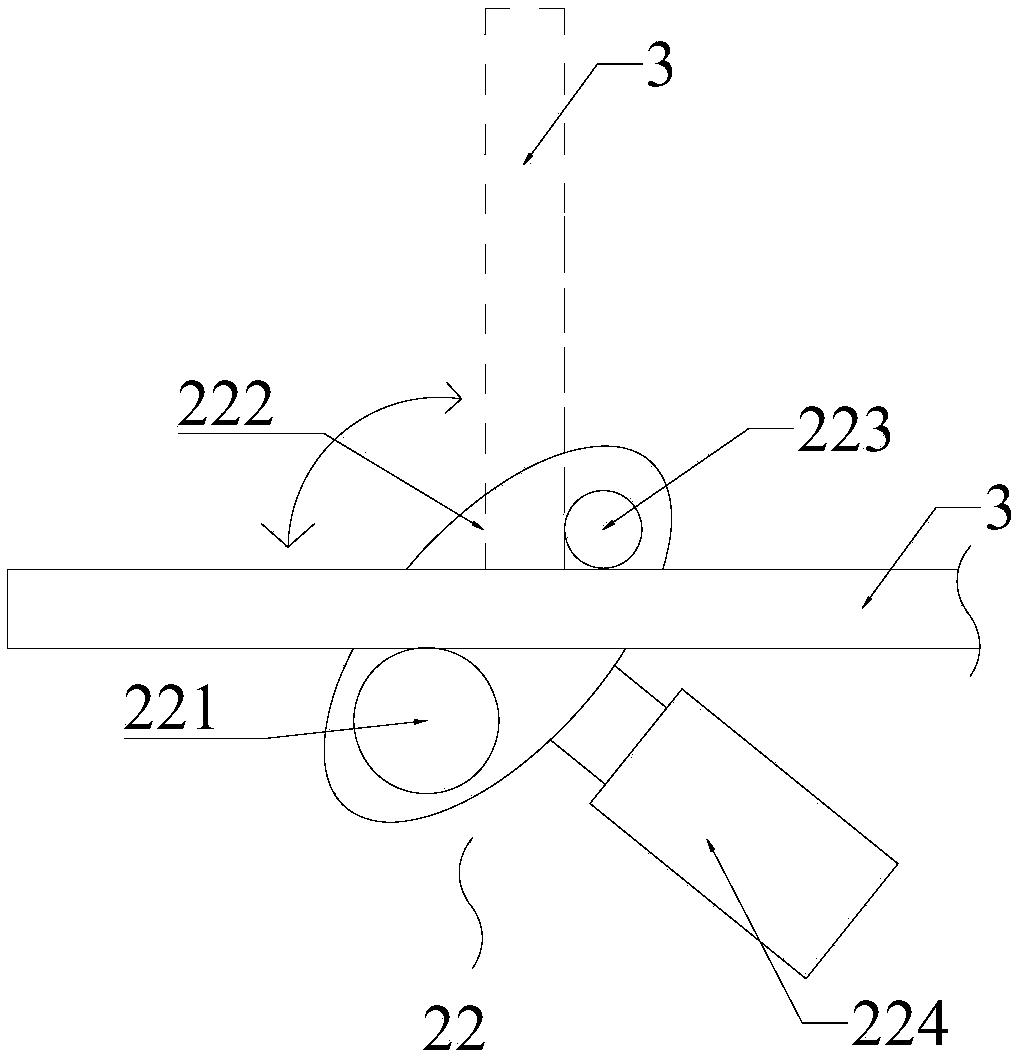

Equipment for laying, welding and cutting aluminum foils on surface of cylindrical core die

The invention discloses equipment for laying welding and cutting aluminum foils on the surface of a cylindrical core die. The equipment comprises an operating platform, wherein an aluminum foil frame mechanism, a guide mechanism, a core die bracket mechanism and an ultrasonic welding mechanism are sequentially arranged on the operating platform along the conveying direction of the aluminum foils. Continuous rolling-over of a roll-over stand in the core die bracket mechanism realizes that the aluminum foils are coated on the surface of the core die, a strip pressure plate fixed on the roll-over stand rolls over synchronously with the roll-over stand, and the aluminum foils are seamlessly wrapped on the surface of the core die during the rotation of the whole die core. The equipment smoothly and uniformly coats the aluminum foils with small thickness on the surface of the core die, so as to obtain composite material circular tubes with aluminum foil inner liners.

Owner:RES INST OF PHYSICAL & CHEM ENG OF NUCLEAR IND

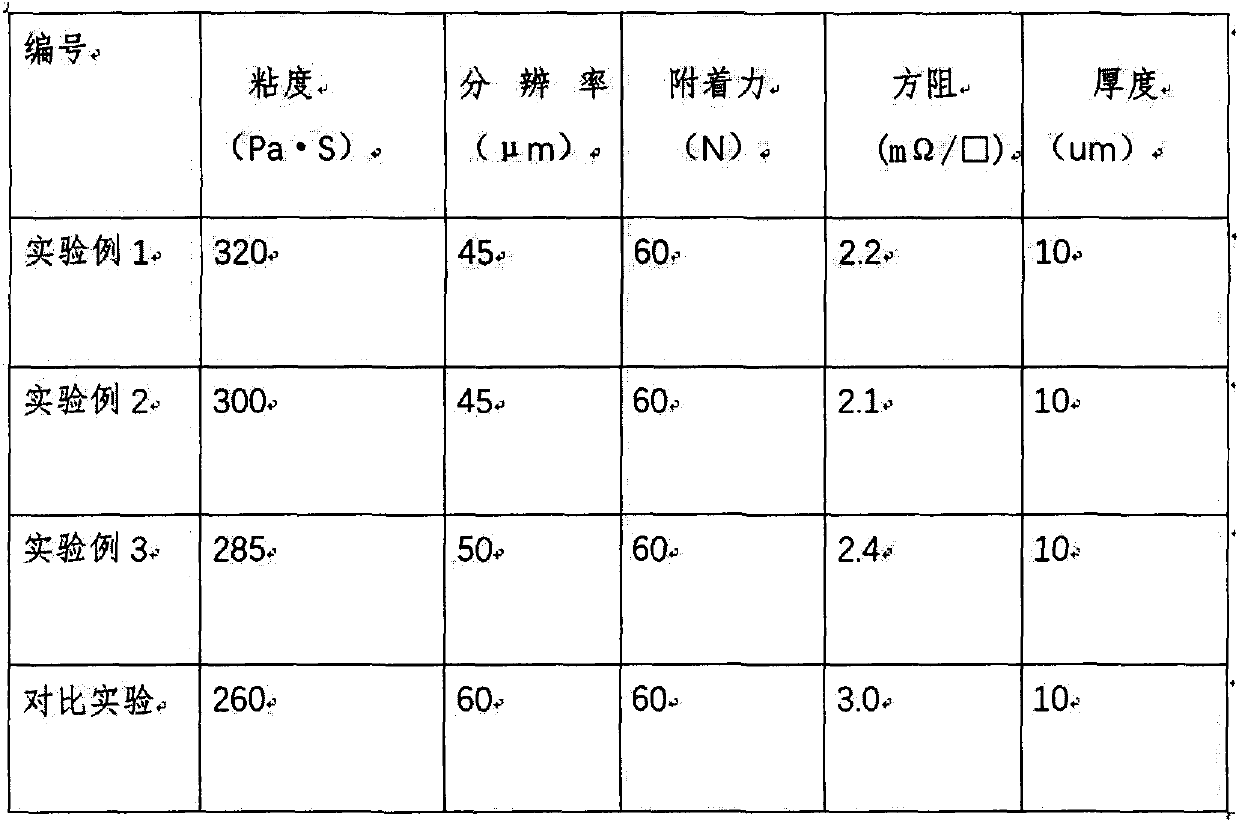

Preparation method for wrapping surface of sheet-shaped silver powder with nano-silver particles

InactiveCN109773211ALower volume resistivityReduce the introduction of pollution sourcesNanotechnologyWater solubleMetal

The invention discloses a preparation method for wrapping the surface of sheet-shaped silver powder with nano-silver particles, and belongs to the technical field of metal materials used for electronic slurry. A reducing solution is prepared by using ascorbic acid and a water-soluble dispersing agent; silver nitrate serves as a silver source; acid serves as a shape regulator; a mixed solution in quantitative ratio is subjected to a reduction reaction in a tubular reactor under the reaction temperature of 40 DEG C to obtain single-dispersion sheet-shaped silver powder with the side length of 0.8-1.2 microns and the thickness of 40 nanometers; then, an oriented nucleation agent solution and a certain numberof ascorbic acid reducing agent are added into a silver powder suspension solution, and the nano-silver particles directionally grow on the surface of the sheet-shaped silver powder; after the reaction is completed, an ethanol solution containing a surface modifier is added for rapid stirring for 30-60 minutes; and washing, filtering, drying and sieving are carried out to obtain the high-dispersion sheet-shaped silver powderwith the surface wrapped with thenano-silver particles. The sheet-shaped silver powder prepared by the preparation method is high in tap density, good in dispersibility and uniformity and high in sintering activity. Compared with traditional sheet-shaped silver powder, conductive slurry prepared by the silver powder can significantly reduce the volume resistivity, the thixotropy is good, and requirements for precise printing can be met.

Owner:NANJING UNIV OF TECH

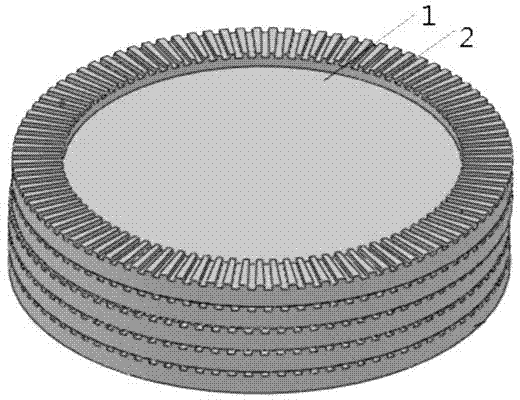

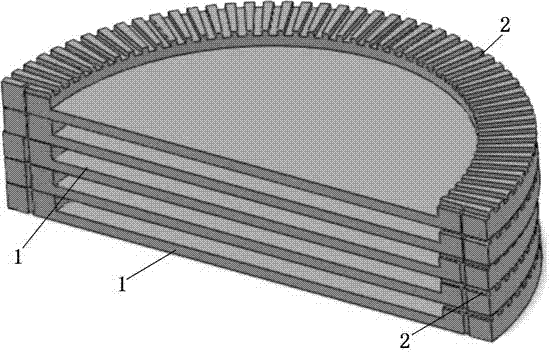

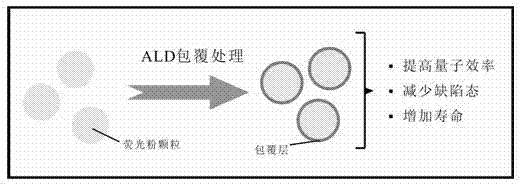

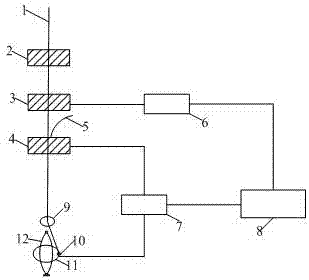

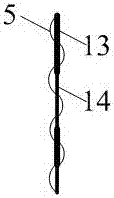

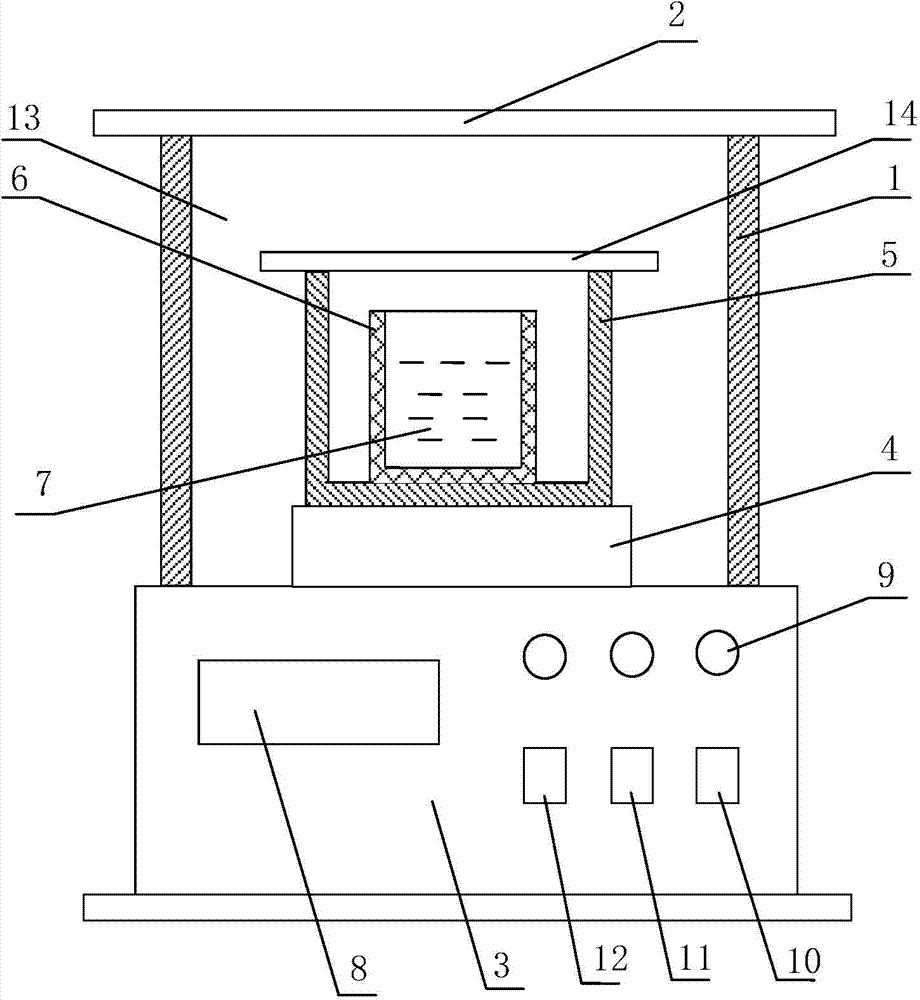

Silicate type fluorescent powder as well as device and process for coating oxide diaphragm film on surface of fluorescent powder

ActiveCN103668119AMeet the requirements for wrappingPrecise thickness controlChemical vapor deposition coatingMaterials scienceChemical engineering

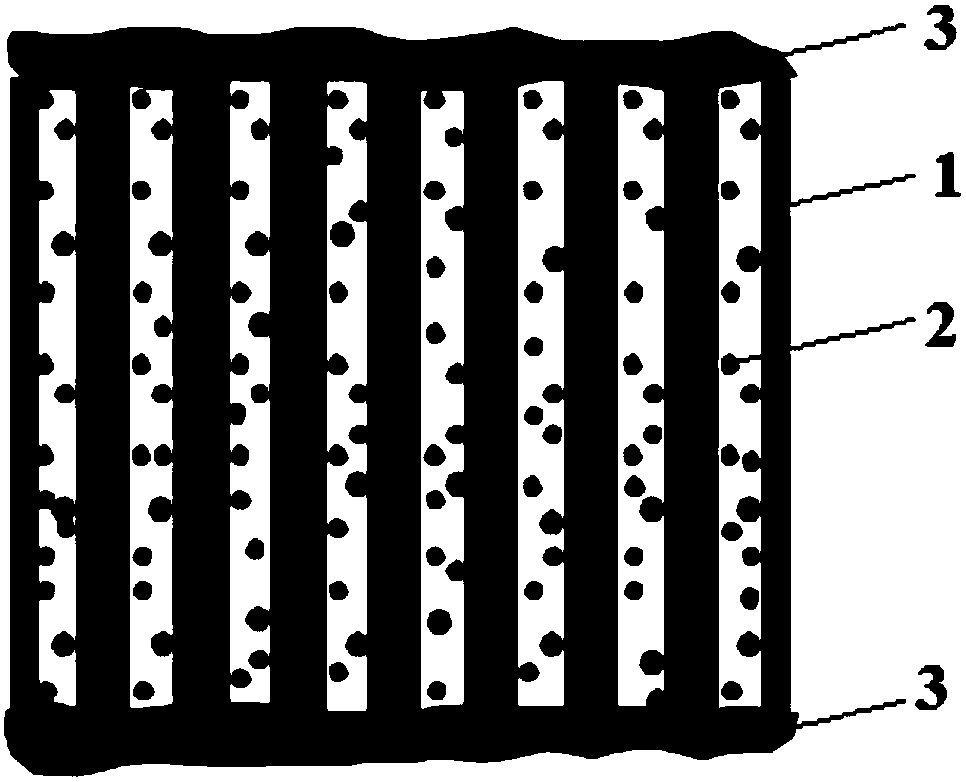

The invention discloses silicate type fluorescent powder as well as a device and process for coating an oxide diaphragm film on the surface of the fluorescent powder. A fluorescent powder special deposition chamber is arranged in the device and has a single-layer or multi-layer structure, wherein each layer of the deposition chamber consists of a fluorescent powder deposition area (1) and air passages (2) bestrewn around the deposition area (1), and the air passages are pipelines for feeding and discharging a precursor and carrier gas for atomic layer deposition. The invention realizes the aim of coating a diaphragm film layer at the periphery of the fluorescent powder by using an atomic layer deposition (ALD) technology to improve the performance of the fluorescent powder. The deposition chamber special for coating the fluorescent powder is invented on the basis of the ALD technology, and the process for atomic layer deposition is further improved to meet requirements for coating the fluorescent powder.

Owner:江苏迈纳德微纳技术有限公司

Automatic steel belt automatic bundle strapping machine

The invention provides an automatic steel belt automatic bundle strapping machine, and belongs to the field of steel bundling. The machine comprises an objective table used for placing objects to be bundled, and further comprises forming mechanisms, the two forming mechanisms are symmetrically arranged on the two sides of the objective table, each forming mechanism comprises a first bending deviceand at least one second bending device, the first bending device is arranged between the objective table and the second bending device, the first bending device for pressing and covering a packagingbelt on the objects to be bundled is arranged on the outer side of the objective table, at least one second bending device is arranged on the outer side of the first bending device, the second bendingdevice and the first bending device are distributed along a first path, the second bending device is used for bending the side of the packaging belt according to the stacking shape of the objects tobe bundled, and the first bending device and the second bending device are close to or away from the objective table along the first path. The automatic steel belt automatic bundle strapping machine solves the problem that in the prior art, a thick steel belt bundle strapping machine only can carry out bundling according to the single stacking-shaped objects to be bundled.

Owner:石家庄市梓起机电设备科技有限公司

Wrapped bunchy yarn production apparatus

The invention discloses a wrapped bunchy yarn production apparatus, which comprises a front roller, a middle roller and a rear roller; a middle roller shaft and a rear roller shaft are connected by a gear and then driven by a servo motor; a front roller shaft is driven by a main motor; a staple fiber rove is fed in from the rear roller and is stretched to obtain a staple fiber strip that is output from a front roller jaw; a staple fiber spun yarn is fed in from the front roller and merged with the staple fiber strip that is obtained at the front roller jaw after being stretched. A base yarn is produced in a way that the main motor drives the front roller rotate at a rotating speed v1; the servo motor drives the middle roller rotate at the rotating speed v2; and the rear roller rotating speed v3=kv2, wherein, k is determined by the gear teeth number; a ring is produced in a way that the main motor drives the front roller rotate at the rotating speed v1; the servo motor drives the middle roller rotate at the rotating speed v4; and the rear roller rotating speed v5=kv4, wherein, v4 is larger than v2. A twist transmitted from bottom to the top makes the staple fiber strip rotate around its own shaft to obtain a bunchy yarn, at the same time, the staple fiber spun yarn is wrapped on the surface of the bunchy yarn continuously, thereby obtaining the wrapped bunchy yarn.

Owner:HEFEI ANLUYI TECH CO LTD

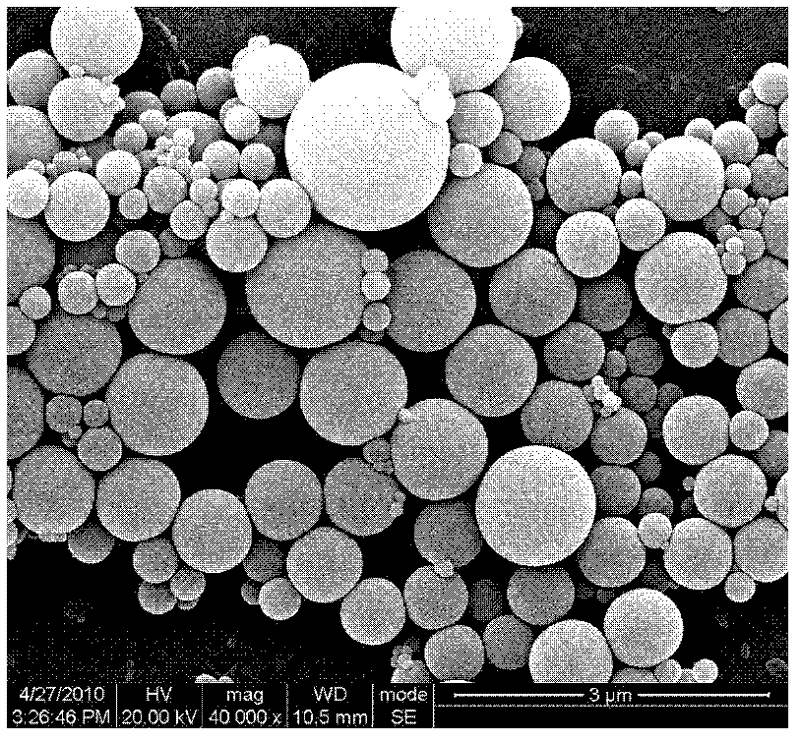

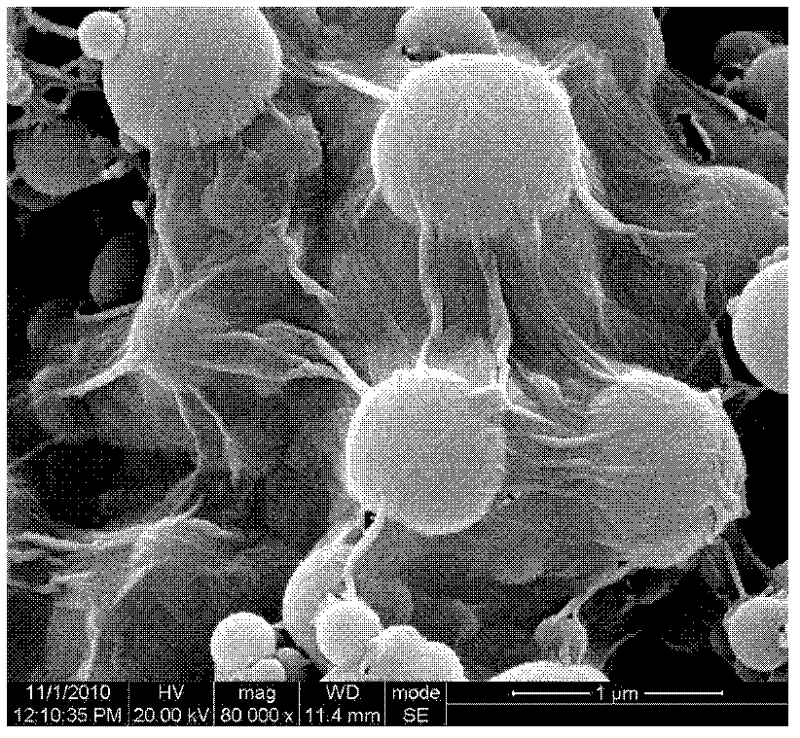

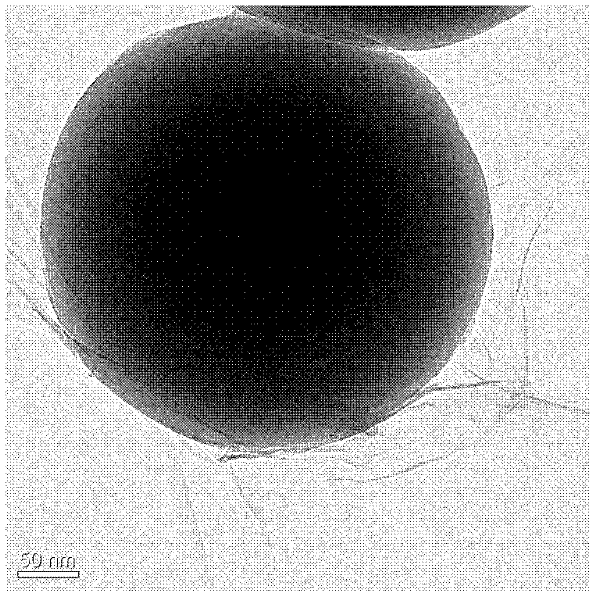

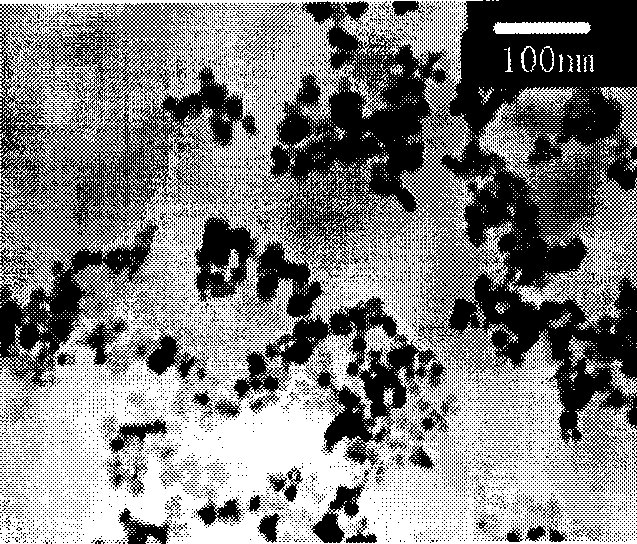

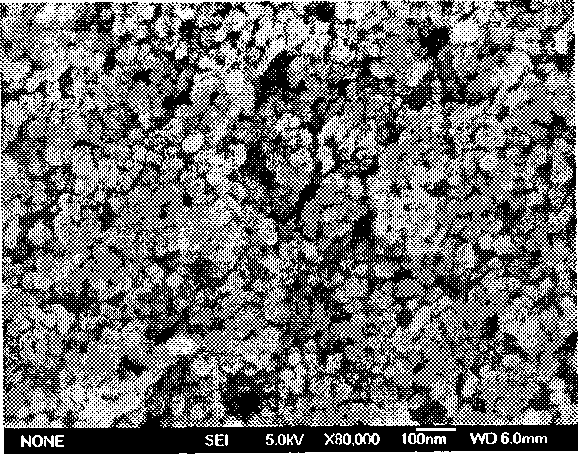

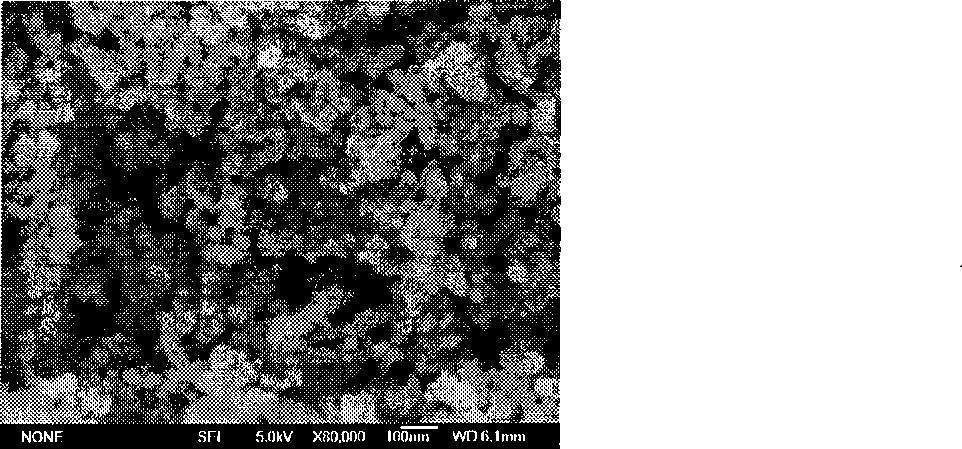

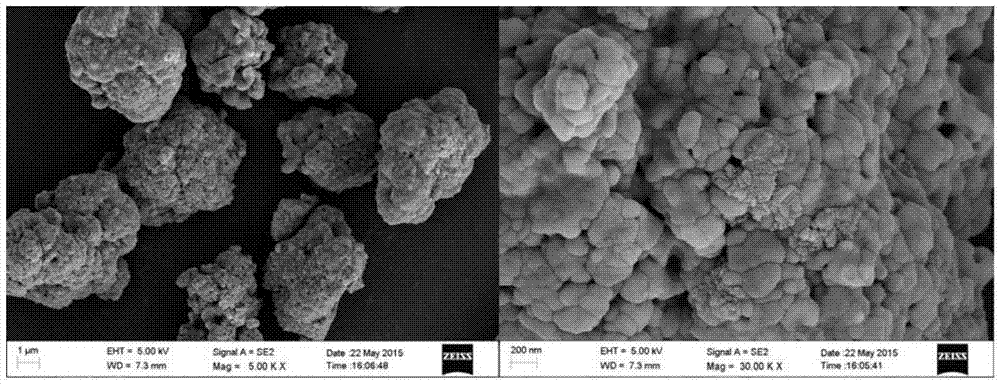

Graphene tightly coated SiO negative electrode material and preparation method thereof

InactiveCN109742363ASolve the problem of low theoretical capacityImprove cycle performanceCell electrodesSecondary cellsState of artCvd graphene

The invention proposes a graphene tightly coated SiO negative electrode material and a preparation method thereof, and solves the problem in the prior art that the theoretical capacity of a battery negative electrode silicon-based raw material is low and the cycle performance is poor. The preparation method of the graphene tightly coated SiO negative electrode material comprises the following steps: step 1), preparation of a surface modified graphene oxide solution; step 2), preparation of an SiO dispersion; step 3), preparation of a graphene oxide coated SiO composite; and step 4), preparation of a graphene coated SiO composite. The method of the invention can completely realize the compact ultra-thin film coated SiO composite of graphene, and the method has the advantages of being simplein preparation process, low in cost, short in cycle and environmentally friendly, and can realize macro preparation.

Owner:圣盟(廊坊)新材料研究院有限公司

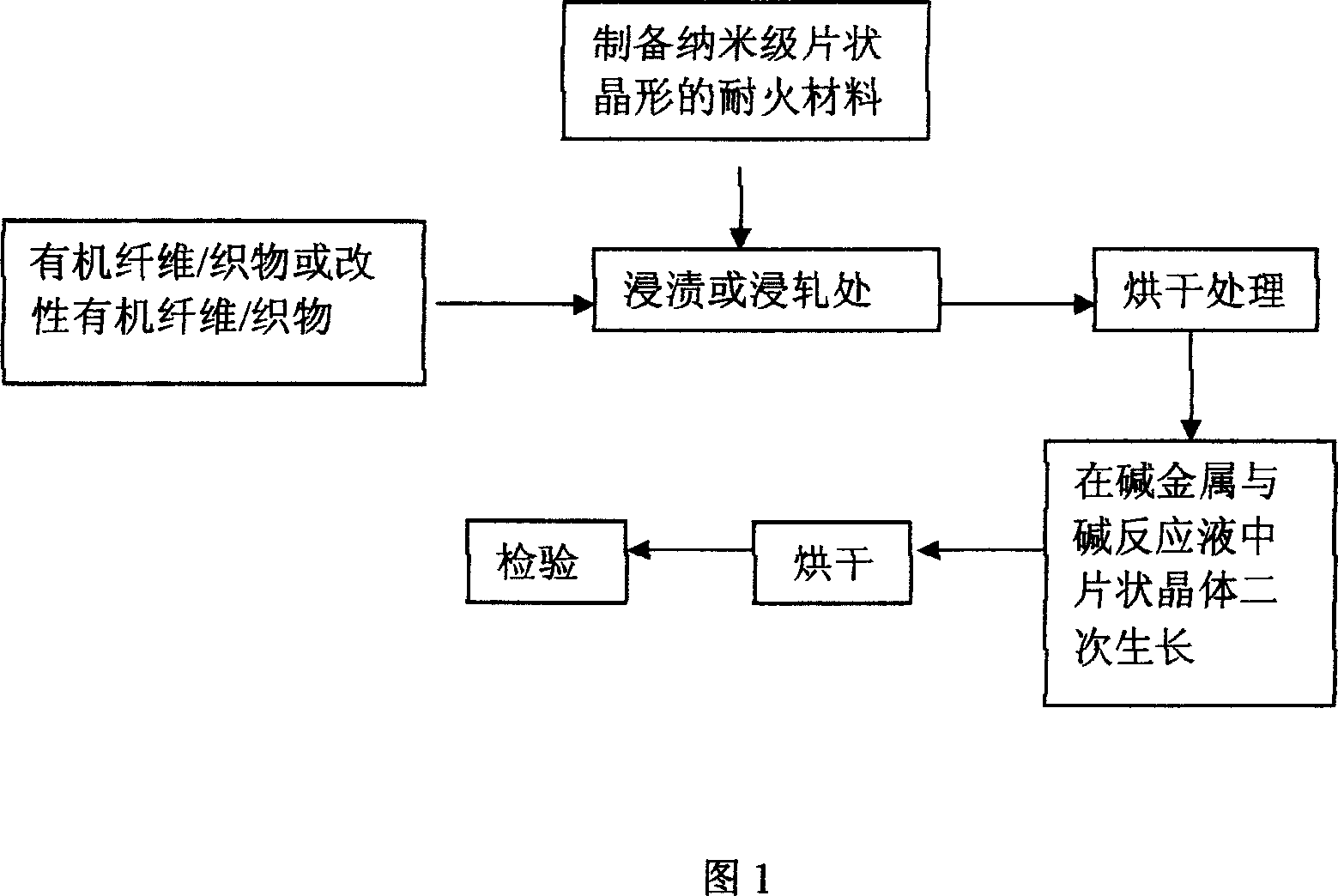

Flame resisting heat insulating conditioning method for orgainic fiber fabric

InactiveCN1932135AAchieve wrappingNo pollution in the processFibre treatmentFiberAgricultural engineering

The present invention discloses a finishing method for raising heat-insulating and flame-proofing performance of organic fibre fabrics. Said method is characterized by forming a continuous protective film made of sheet hydroxide on the surface of organic fibre or fabrics so as to raise flame-proofing and heat-insulating performance of organic fibre fabrics.

Owner:DONGHUA UNIV

Preparation method of hybrid carbon silver composite material

The invention relates to a preparation method of a hybrid carbon silver composite material. For overcoming the defects of carbon and silver themselves, glucose is used as a carbon source, silver nitrate is used as a hybrid agent, a hydrothermal synthesis method is adopted, and therefore the effect that the silver is coated with and loaded by the carbon is realized. The preparation method is advanced in technology, rapid and accurate and complete in data, carbon silver hybridization improves physical and chemical properties, the application range is enlarged, a product is brownish red powder, the diameter of a powder particle is less than or equal to 700nm, the product is good in purity, the purity can reach ninety nine percent, the production yield is high and can reach ninety seven point five percent, the product can be matched with various chemicals to generate new products to be used, and therefore the preparation method of the hybrid carbon silver composite material is very ideal.

Owner:TAIYUAN UNIV OF TECH

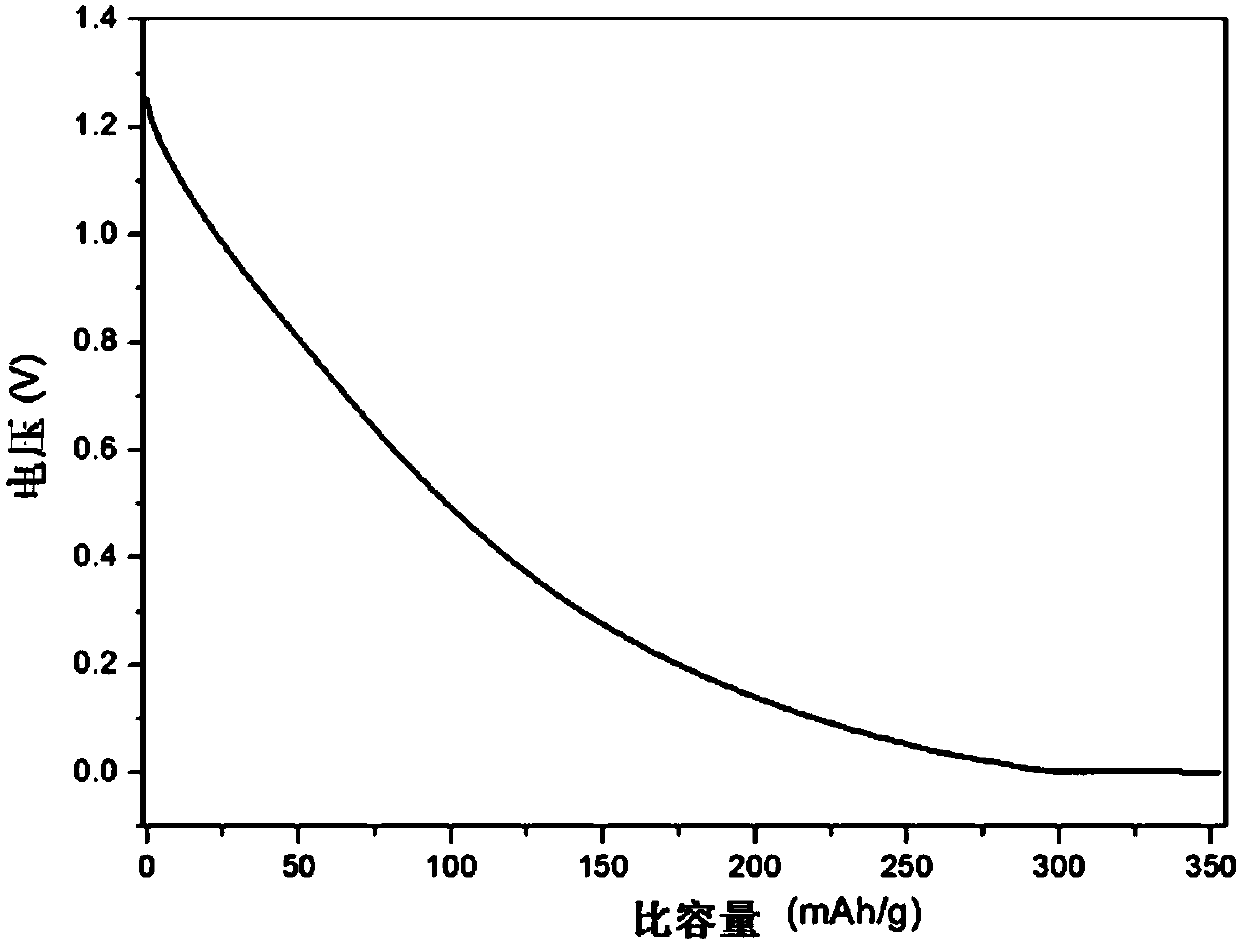

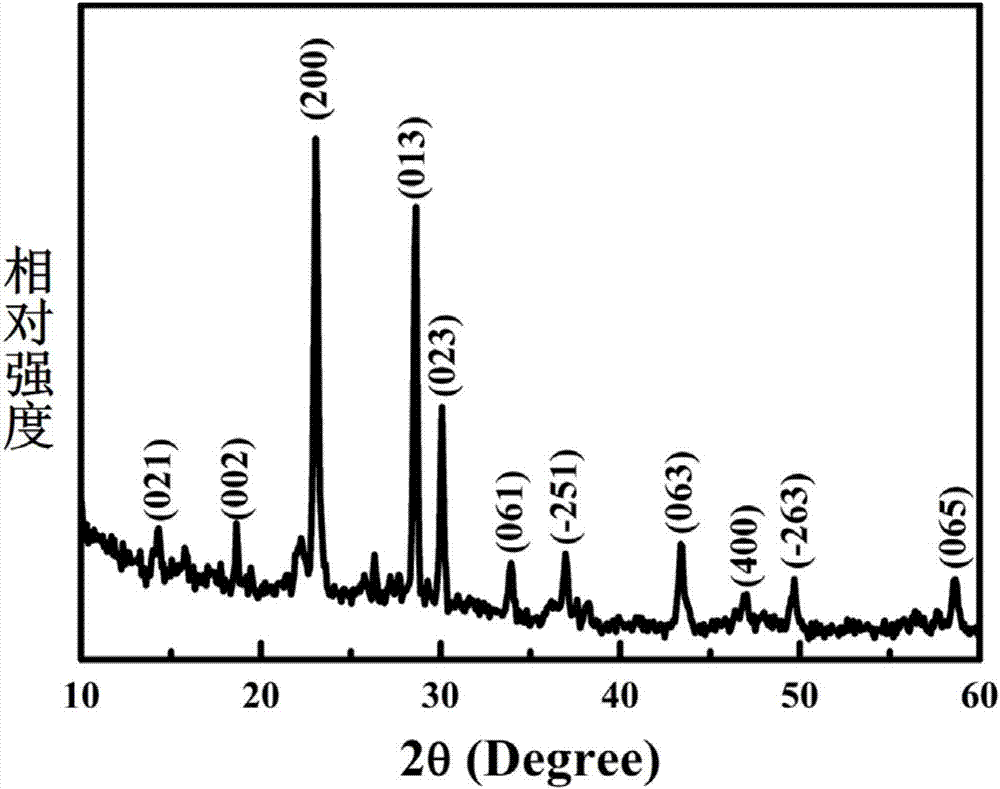

Preparation method of high-performance sodium ion battery cathode material (VO)2P2O7 composite

ActiveCN107256953AImprove electrochemical performanceImprove conductivityCell electrodesSecondary cellsIonCarbon coating

The invention relates to a preparation method of a high-performance sodium ion battery cathode material (VO)2P2O7 composite. The preparation method includes: evenly stirring a vanadium source V, a phosphorus source P and a monomer polymer with water, heating in 70-95DEG C water bath, adding an initiator, transferring to an oven for drying 4-6 hours at 100-120DEG C and grinding to obtain precursor powder; placing the precursor powder in a tube furnace in the inert atmosphere, and gradually heating to 450-800DEG C for sintering for 4-8 hours to obtain the high-performance sodium ion battery cathode material (VO)2P2O7 composite. The raw materials adopted are easy to obtain, low in price, environment friendly and low in time and energy consumption, and high-volume low-cost production can be achieved; next calcination can be performed after pretreatment in the water bath at the lower temperature, and requirement on equipment is low; carbon-coating can be realized, and meanwhile, carbon thermal reduction is realized.

Owner:ZAOZHUANG UNIV

Preparation method of high-temperature thermal insulation tile containing mullite fiber

The invention relates to a preparation method of a thermal insulation tile containing ceramic fiber. The ceramic fiber is sheared with fiber crushing equipment and chopped fiber is obtained; condensedtype dimethyl silicone rubber and dimethicone are mixed and premix rubber is obtained; mullite fiber is added and fiber slurry is obtained; an initiator is added to the slurry, the slurry is poured into suction filtration equipment for suction filtration treatment; a wet body is subjected to primary drying-demolding-secondary drying treatment and a dried body is obtained; the body is placed in ahigh-temperature furnace for rubber removal and sintering, and the thermal insulation tile containing the ceramic fiber is obtained. The thermal insulation tile has the density of 0.29 g / cm<3>-0.53 g / cm<3>, compressive strength of 0.7 MPa-1.9 MPa and temperature resistance up to 1,500 DEG C, and a binder can better coat the fiber. The problem that the binder is not dispersed in place during preparation of the thermal insulation tile containing the mullite fiber is solved. The thermal insulation tile containing the mullite fiber can bear the high temperature of 1,500 DEG C and can be applied tohypersonic speed spacecrafts.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com