Equipment for laying, welding and cutting aluminum foils on surface of cylindrical core die

A cylindrical and mandrel technology, applied in the field of equipment used for laying, welding and cutting aluminum foil on the surface of cylindrical mandrel, it can solve the problem that it is difficult to straighten and cut thoroughly, the aluminum foil is torn, and the aluminum foil cannot be tightly attached. Ground covering and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

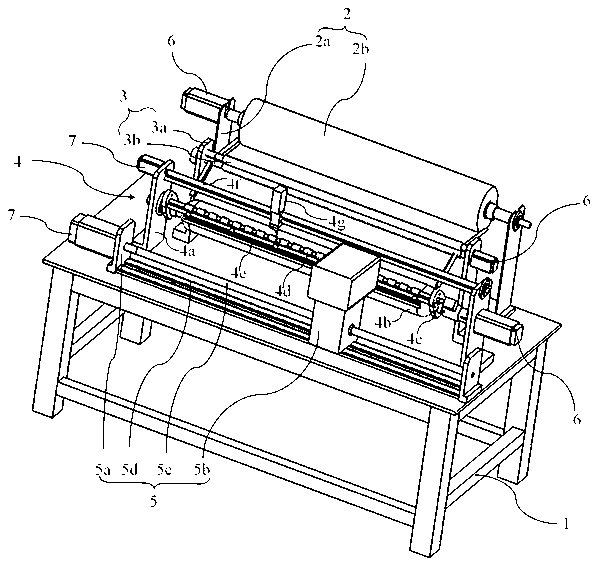

[0024] Below, with reference to the accompanying drawings and examples, the equipment for laying, welding and cutting aluminum foil on the surface of a cylindrical core mold of the present invention will be described in detail:

[0025] like figure 1 As shown in the figure, a device for laying, welding and cutting aluminum foil on the surface of a cylindrical core mold includes a workbench 1, and an aluminum foil frame mechanism 2 and a material guide mechanism 3 are sequentially arranged on the workbench 1 along the conveying direction of the aluminum foil. , Mandrel bracket mechanism 4 and ultrasonic welding mechanism 5.

[0026] The aluminum foil rack mechanism 2 includes an aluminum foil support 2a with grooves on both sides, an aluminum foil roll 2b, and a stepping motor 6 connected to one end of the aluminum foil roll 2b and located outside the aluminum foil support 2a at the left end, and the aluminum foil roll 2b is installed on the aluminum foil support. 2a on.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com