Preparation method of high-temperature thermal insulation tile containing mullite fiber

A mullite fiber and heat-insulating tile technology, which is applied in the preparation of mullite fiber high-temperature heat-insulating tiles, and in the field of polymer gel molding to prepare mullite fiber high-temperature heat-insulating tiles, can solve the problem of binder dispersion. In place and other issues to achieve the effect of optimizing performance and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A method for preparing mullite fiber high-temperature heat-insulating tiles, comprising the following steps:

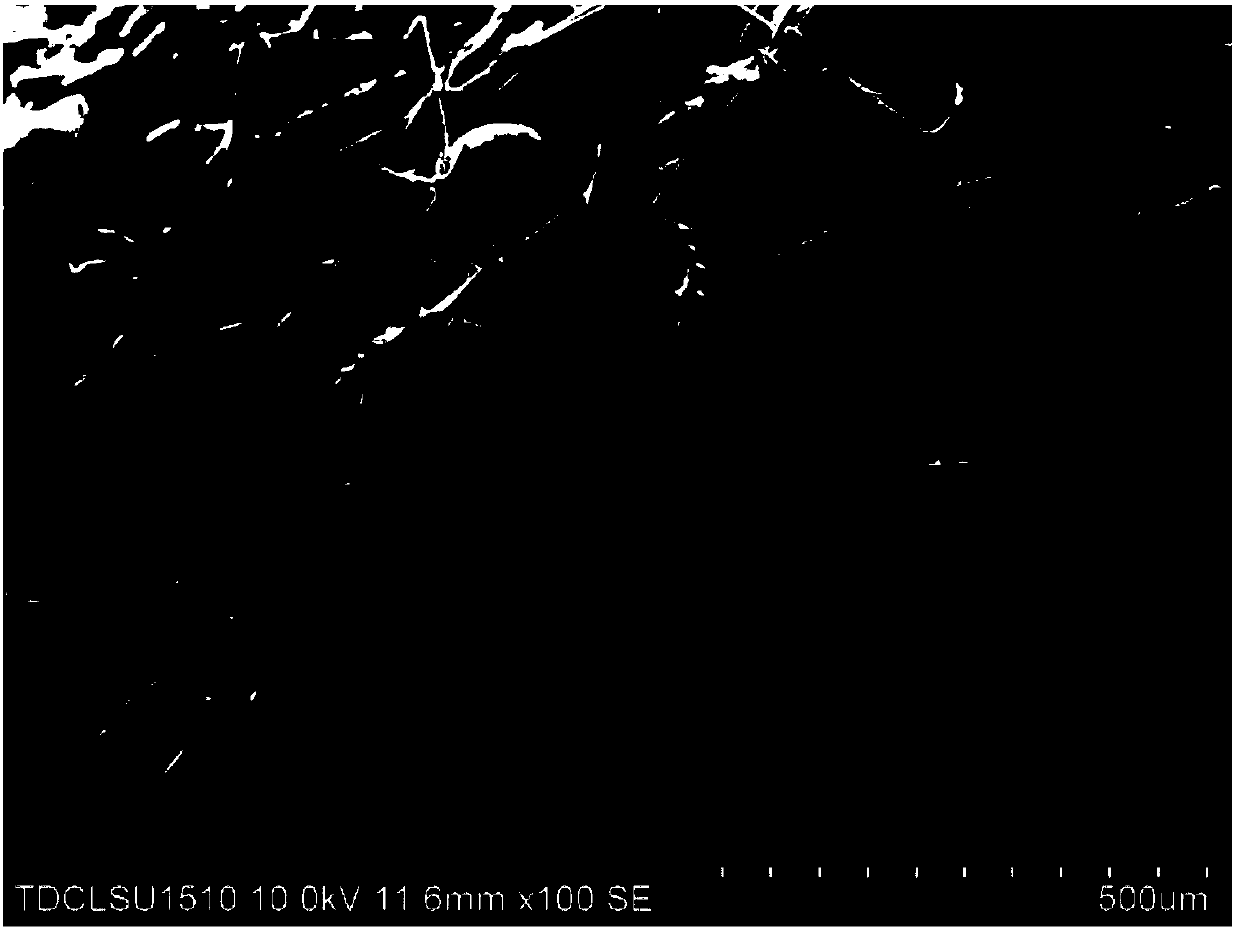

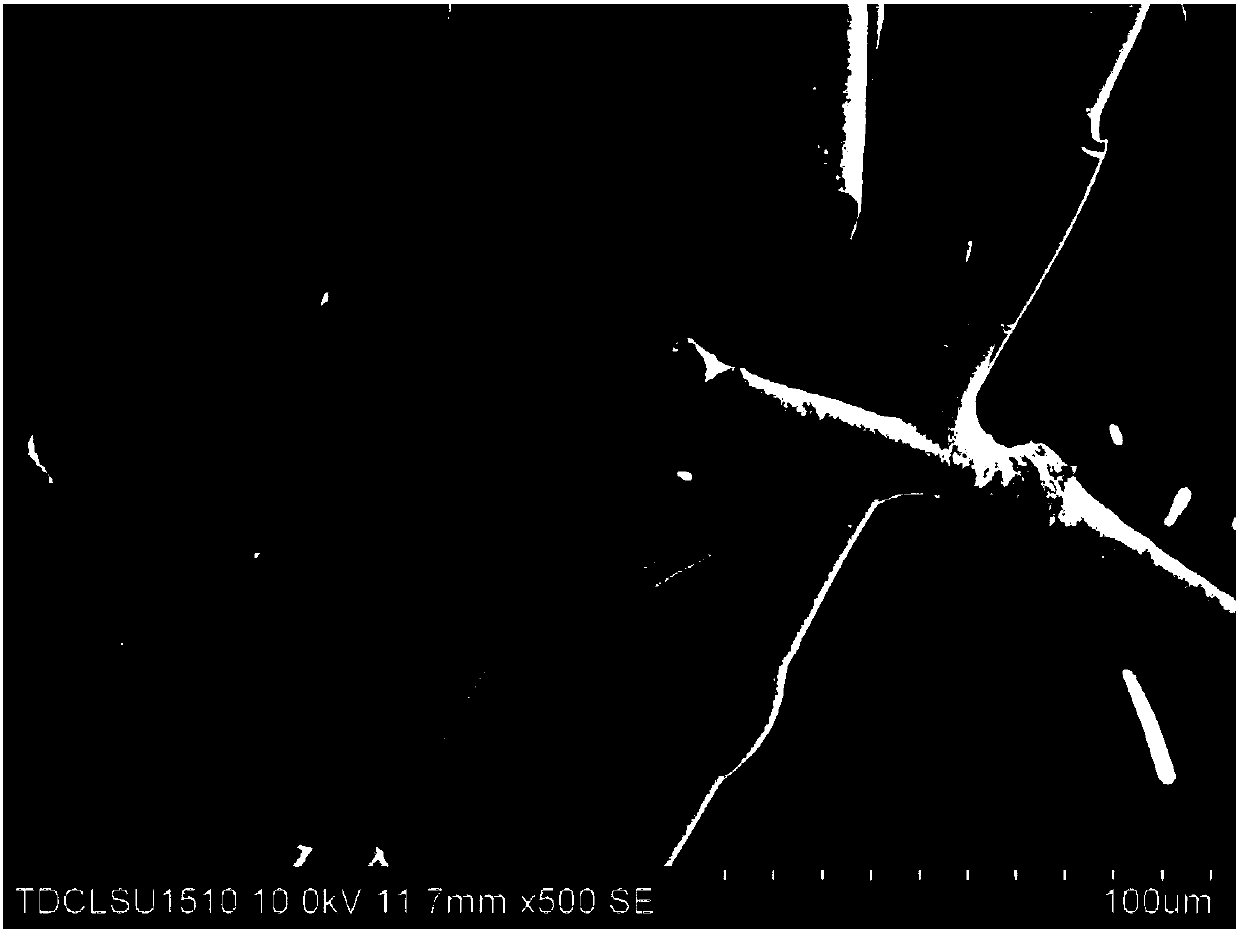

[0031] (1) Shorten mullite long fibers using fiber crushing equipment, the shearing time is 4min to 6min, to obtain chopped mullite fibers with a length of 400 μm to 600 μm;

[0032] (2) Use condensation-type dimethyl silicone rubber as an adhesive, use dimethyl silicone oil as a diluent, and mix according to the mass ratio of condensation-type dimethyl silicone rubber: dimethyl silicone oil = 100: (45-75) Evenly, stir in a water bath at 40°C to 60°C for 1h to 2h to obtain a premixed colloid;

[0033] (3) According to the mass ratio of mullite chopped fiber and premixed colloid (20~40): 100, take the mullite chopped fiber prepared in step (1), and take the premixed colloid obtained in step (2). For colloidal mixing, add mullite chopped fibers to the premixed colloid during stirring in a water bath at 40°C to 60°C, and stir vigorously for 2h to 4h until the fib...

Embodiment 1

[0039] In this embodiment, a method for preparing a mullite fiber high-temperature heat-insulating tile is specifically carried out according to the following steps:

[0040] (1) Shorten mullite long fibers using fiber crushing equipment, and the shearing time is 6 minutes to obtain chopped mullite fibers with a length of 400 μm;

[0041] (2) Use condensation-type dimethyl silicone rubber as an adhesive, use dimethyl silicone oil as a diluent, mix evenly according to the mass ratio of condensation-type dimethyl silicone rubber: dimethyl silicone oil = 100:75, and mix at 40 ℃ water bath and stirred for 2 hours to obtain the premixed colloid;

[0042] (3) according to the mass ratio of mullite chopped fiber and premixed colloid is 40:100, get the mullite chopped fiber prepared in step (1), get the premixed colloid obtained in step (2), in During stirring in a water bath at 40°C, add mullite chopped fibers to the premixed colloid, and stir vigorously for 4 hours until the fibers...

Embodiment 2

[0049] In this embodiment, a method for preparing a mullite fiber high-temperature heat-insulating tile is specifically carried out according to the following steps:

[0050] (1) Shorten mullite long fibers using fiber crushing equipment, and the shearing time is 5 minutes to obtain chopped mullite fibers with a length of 500 μm;

[0051] (2) Use condensation-type dimethyl silicone rubber as an adhesive, use dimethyl silicone oil as a diluent, mix evenly according to the mass ratio of condensation-type dimethyl silicone rubber: dimethyl silicone oil = 100:60, and mix at 50 ℃ water bath and stirred for 2 hours to obtain the premixed colloid;

[0052] (3) according to the mass ratio of mullite chopped fiber and premixed colloid is 30:100, get the mullite chopped fiber prepared in step (1), get the premixed colloid obtained in step (2), in During stirring in a water bath at 50°C, add mullite chopped fibers to the premixed colloid, and stir vigorously for 3 hours until the fibers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com