Method for preparing non-metallic element doped carbon coated metal nanoparticle magnetic composite

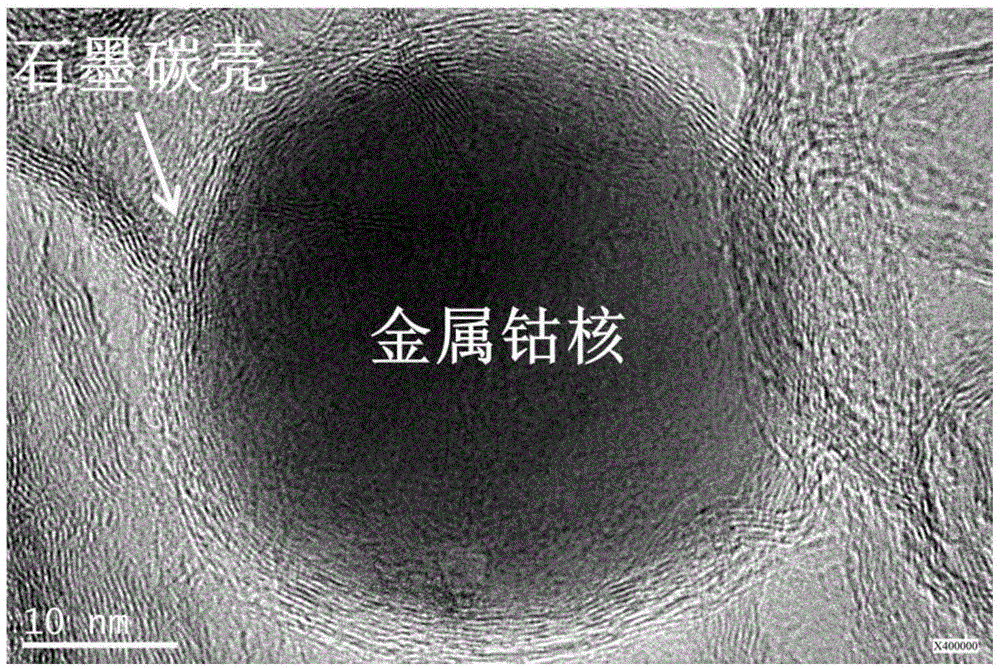

A technology of metal nanoparticles and magnetic composite materials, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of inability to pyrolyze metal precursors, non-metal element doping, and non-magnetic carbon-coated materials , to achieve the effect of high degree of graphitization, large specific surface area and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

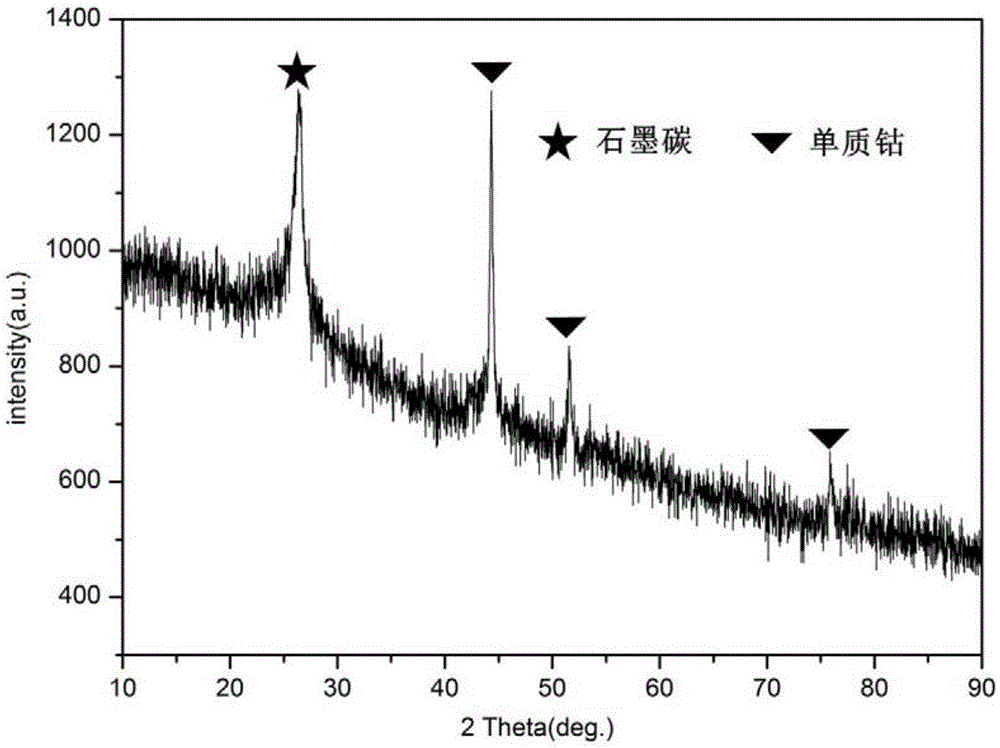

[0032] (1) Weigh 10.09g (120mmol) dicyandiamide (C 2 h 4 N 4 ) and 2.445g (8.4mmol) cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2O) add in the beaker that contains 300mL methanol solution, continue to stir 20min under the condition of 50 ℃, obtain homogeneous phase clear solution; Obtain homogeneous phase powder after homogeneous phase clear solution is dried, grind; Homogeneous phase powder is placed in quartz tube, Place the quartz tube in the uniform temperature zone of the tubular resistance furnace, raise the temperature to 500°C at a rate of 10°C / min in a nitrogen atmosphere with a flow rate of 0.2mL / min, and keep the temperature constant for 2 hours; then raise the temperature to 700°C, and keep the temperature for 2 hours. hour; after the reaction was finished, the quartz tube was cooled to room temperature in a nitrogen atmosphere to obtain a black powder;

[0033] (2) Put the black powder obtained in step (1) in a beaker, add 300mL of 0.5mol / L sulfuric acid solu...

Embodiment 2

[0039] The preparation method of this embodiment is the same as that of Example 1, the only difference is that the water-soluble metal M 2+ Salt selection 1.670g (8.4mmol) ferrous chloride tetrahydrate (FeCl 2 4H 2 O) to replace cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O), obtained nitrogen-doped carbon-coated iron nanoparticles magnetic composite material.

[0040] The mass of the composite material obtained in this example is ~1.6 g, and the doping rate of nitrogen is ~8%.

[0041] Figure 6 For the XRD diffraction pattern of the nitrogen-doped carbon-coated iron nanoparticle magnetic composite material prepared in this example, it can be seen from the figure that the diffraction peak corresponding to 26 ° is graphite carbon, and the remaining three diffraction peaks correspond to simple substance Iron; there are no other diffraction peaks in the spectrum, indicating that the composite material is of high purity without any impurities.

[0042] Figure 7 The XPS...

Embodiment 3

[0044] The preparation method of this embodiment is the same as that of Example 1, the only difference is that the water-soluble metal M 2+ Salt selection 1.997g (8.4mmol) nickel chloride hexahydrate (NiCl 2 ·6H 2 O) to replace cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O) to prepare nitrogen-doped carbon-coated nickel nanoparticle magnetic composite material.

[0045] The mass of the composite material prepared in this embodiment is ~1.3g, and the doping rate of nitrogen is ~7%.

[0046] Figure 8 For the XRD diffraction pattern of the nitrogen-doped carbon-coated nickel nanoparticle magnetic composite material prepared in this example, it can be seen from the figure that the diffraction peak corresponding to 26 ° is graphite carbon, and the remaining three diffraction peaks correspond to simple substance Nickel; there are no other diffraction peaks in the spectrum, indicating that the composite material is of high purity without any impurities.

[0047] Figure 9 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com