Wrapped bunchy yarn production apparatus

A production device and technology of slub yarn, which is applied in the field of spinning, can solve the problems of poor yarn evenness, main draft cannot be adjusted freely, and low transformation cost, and achieve the effect of improving yarn quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

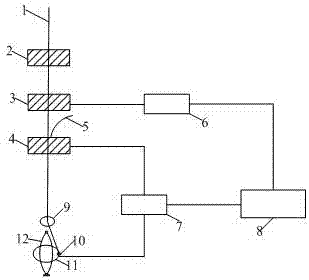

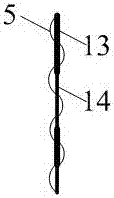

[0011] Depend on figure 1 and figure 2 As shown, a kind of slub wrapping yarn comprises core yarn and outer covering yarn 5, and core yarn comprises base yarn section 14 and slub section 13, and the linear density of base yarn section is less than the linear density of slub section, and slub section is in The core yarn is equally spaced or randomly distributed in the length direction, and the length of the bamboo segments is the same or randomly distributed. The short-fiber aggregates, the raw materials of the short-fiber spun yarn and the spun yarn are the same, and the short-fiber spun yarn is wrapped in the surface of the core yarn in the S-twist or Z-twist direction.

[0012] A wrapping slub yarn production device, including three rows of drafting rollers: front roller 4, middle roller 3 and rear roller 2, the shafts of the middle roller and the rear roller are connected by gears, the shaft of the middle roller is driven by a servo motor 6, and the front roller The roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com