Automatic steel belt automatic bundle strapping machine

A technology of automatic strapping and steel strapping, which is applied to the parts of strapping machinery and other directions to achieve the effect of enhancing strength, increasing breadth, reducing energy consumption and floor space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

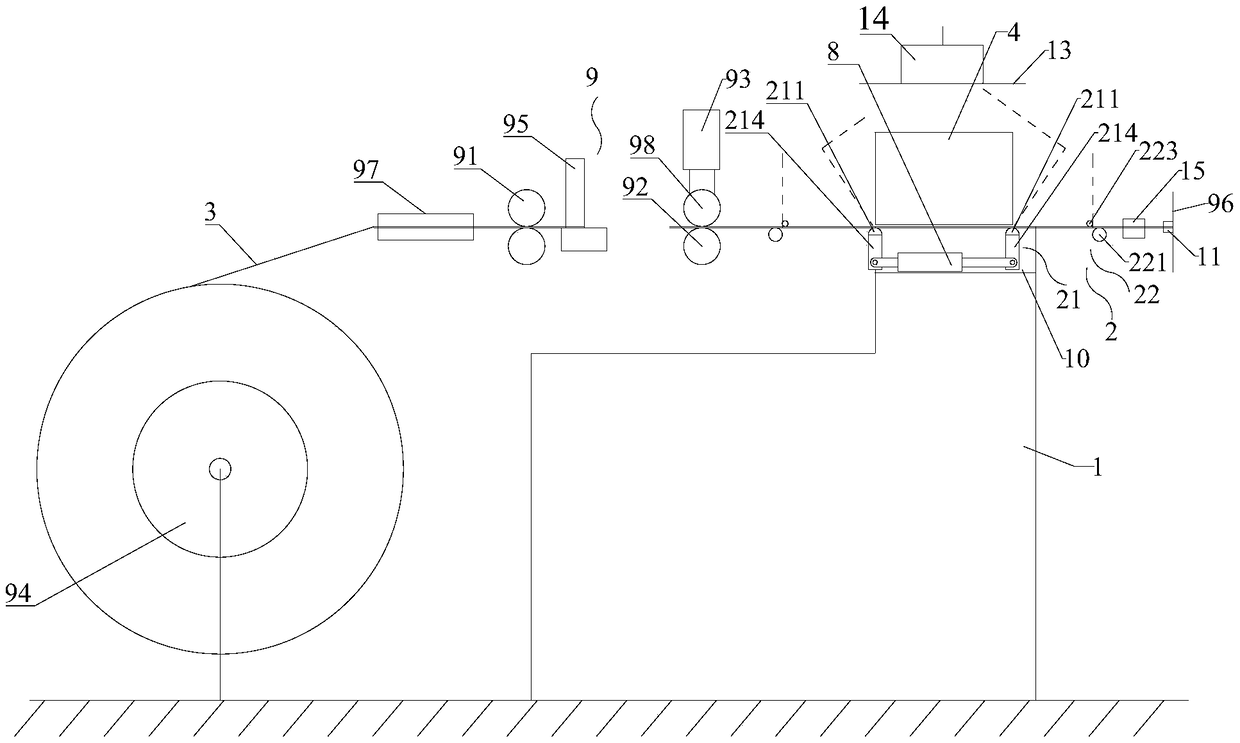

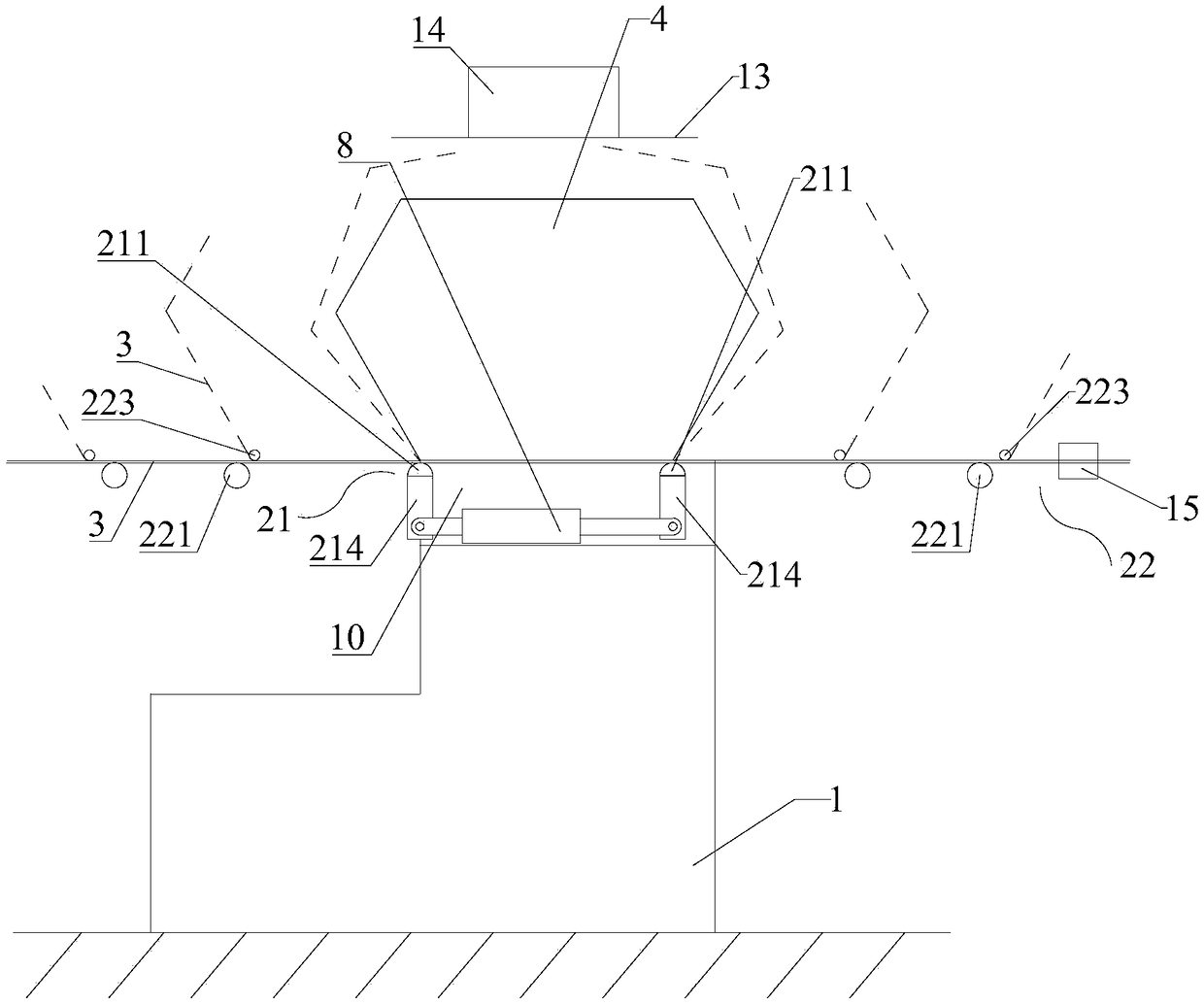

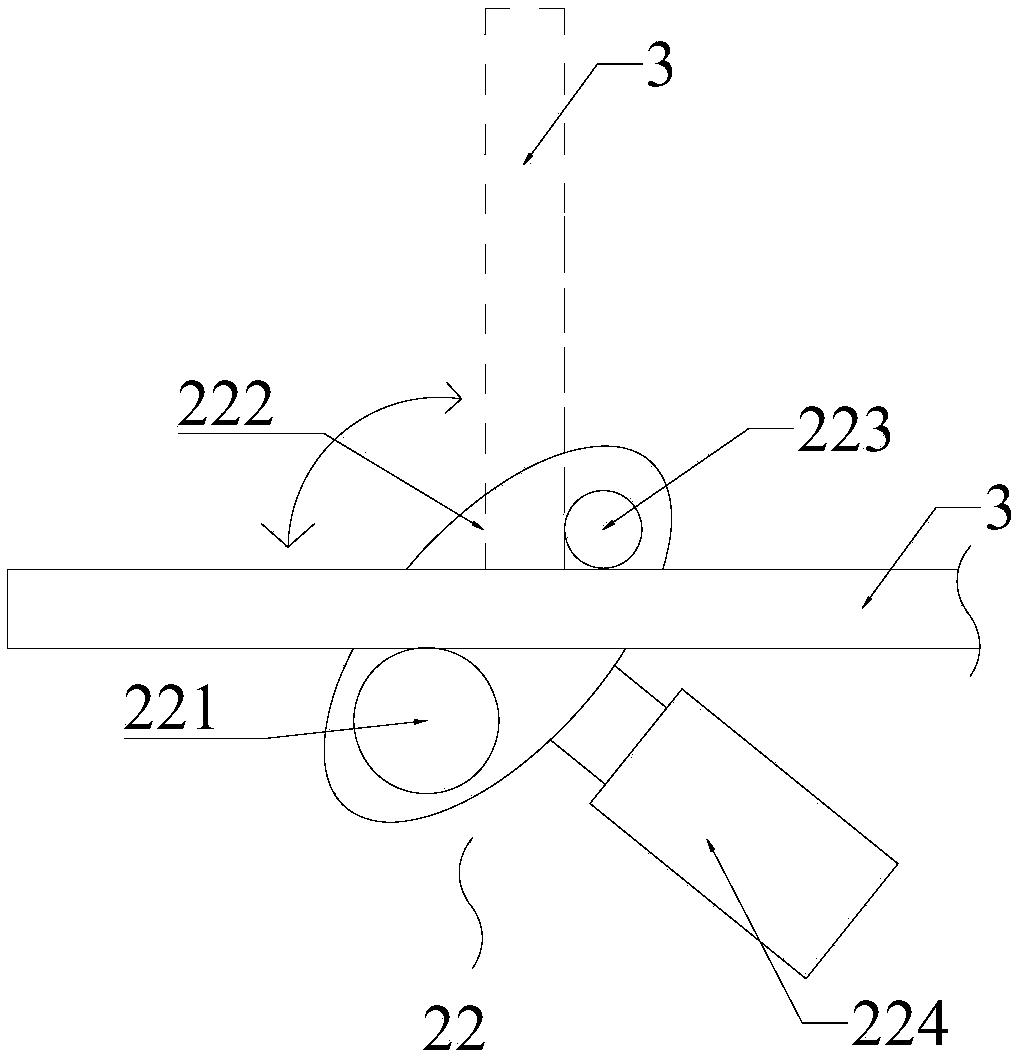

[0078] Further, see figure 1 and figure 2 , as a specific implementation of the steel strip automatic strapping machine provided by the present invention, the forward feeding roller 91 is a pair of rollers,

[0079] Steel strip conveying device 9 also comprises uncoiler 94 and broken belt machine 95, and front feed roll 91 is arranged between uncoiler 94 and broken belt machine 95.

[0080] During use, the packing tape 3 of being rolled is placed on the uncoiler 94, and the free end of packing tape 3 is manually placed in the front feed roller 91, and the packing tape 3 moves to the belt breaking machine under the conveyance of the front feed roller 91. At 95 places, the belt breaking machine 95 removes the head of the packing belt 3, and then the belt breaking machine 95 returns to its original position, and the packing belt 3 continues to be transported forward under the conveying of the front feeding roller 91 until the delivery length of the packing belt 3 reaches the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com