Automatic device used for manufacturing of aluminum pot mold shell

An automatic device and mold technology, applied in the direction of manufacturing tools, casting molding equipment, metal processing equipment, etc., can solve the problems of relying on labor, lack of equipment, poor precision, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

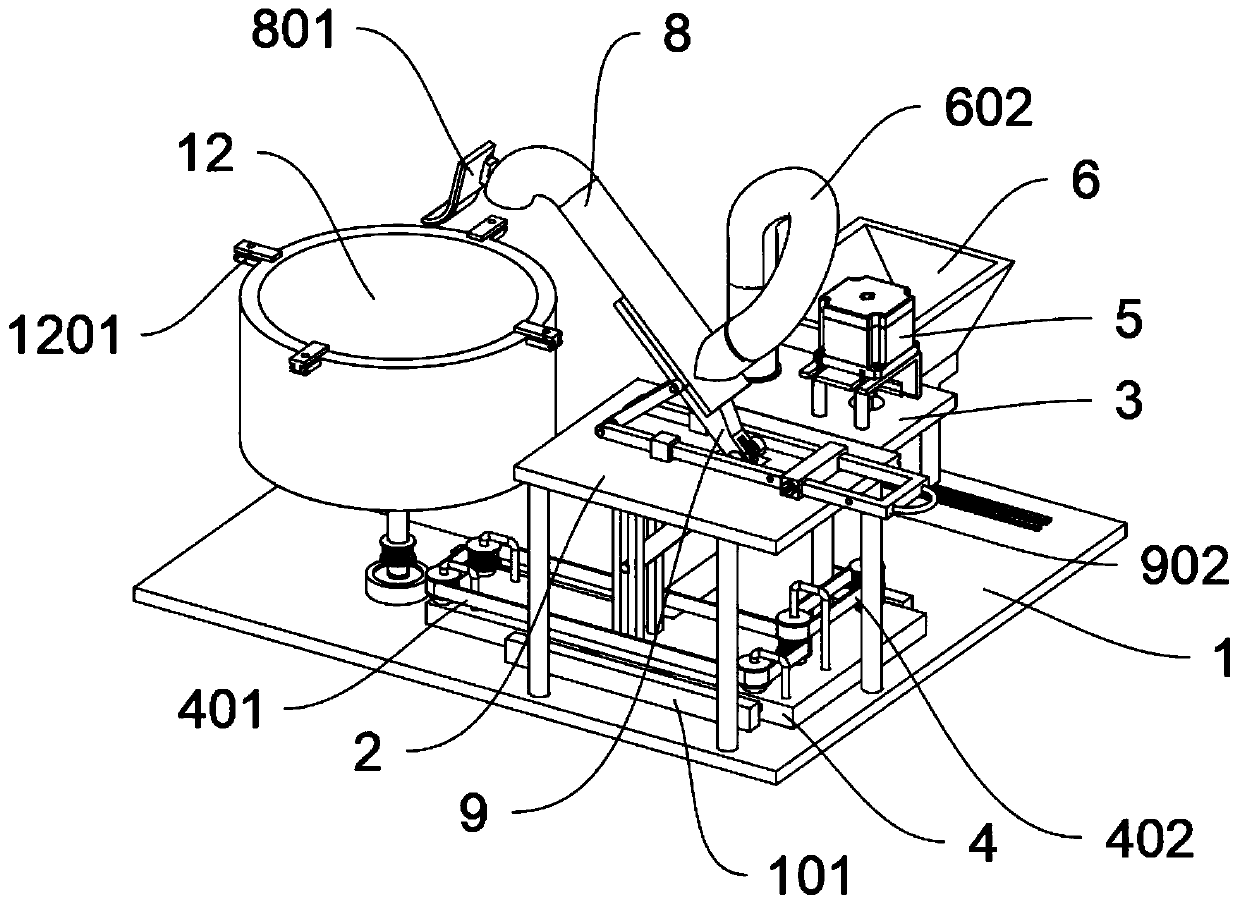

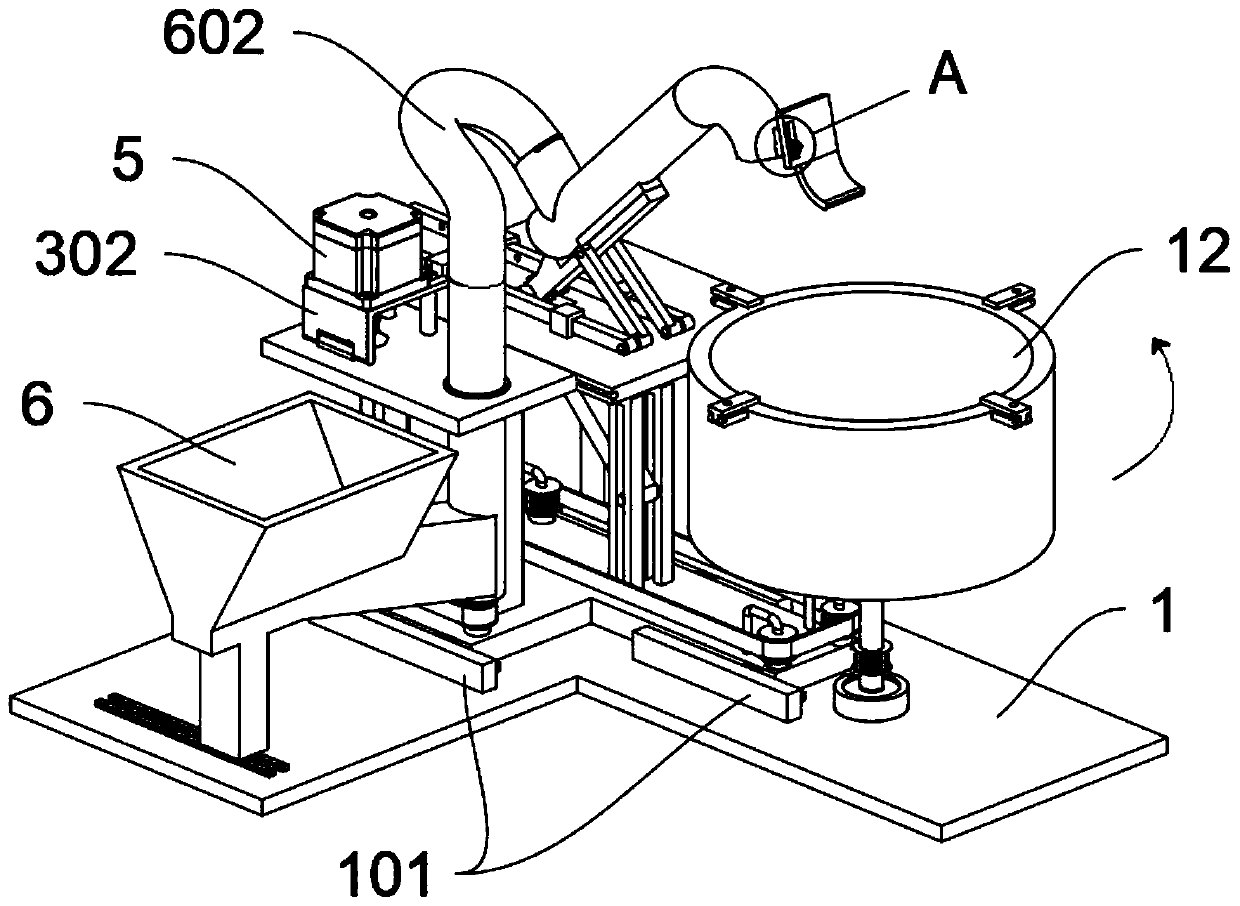

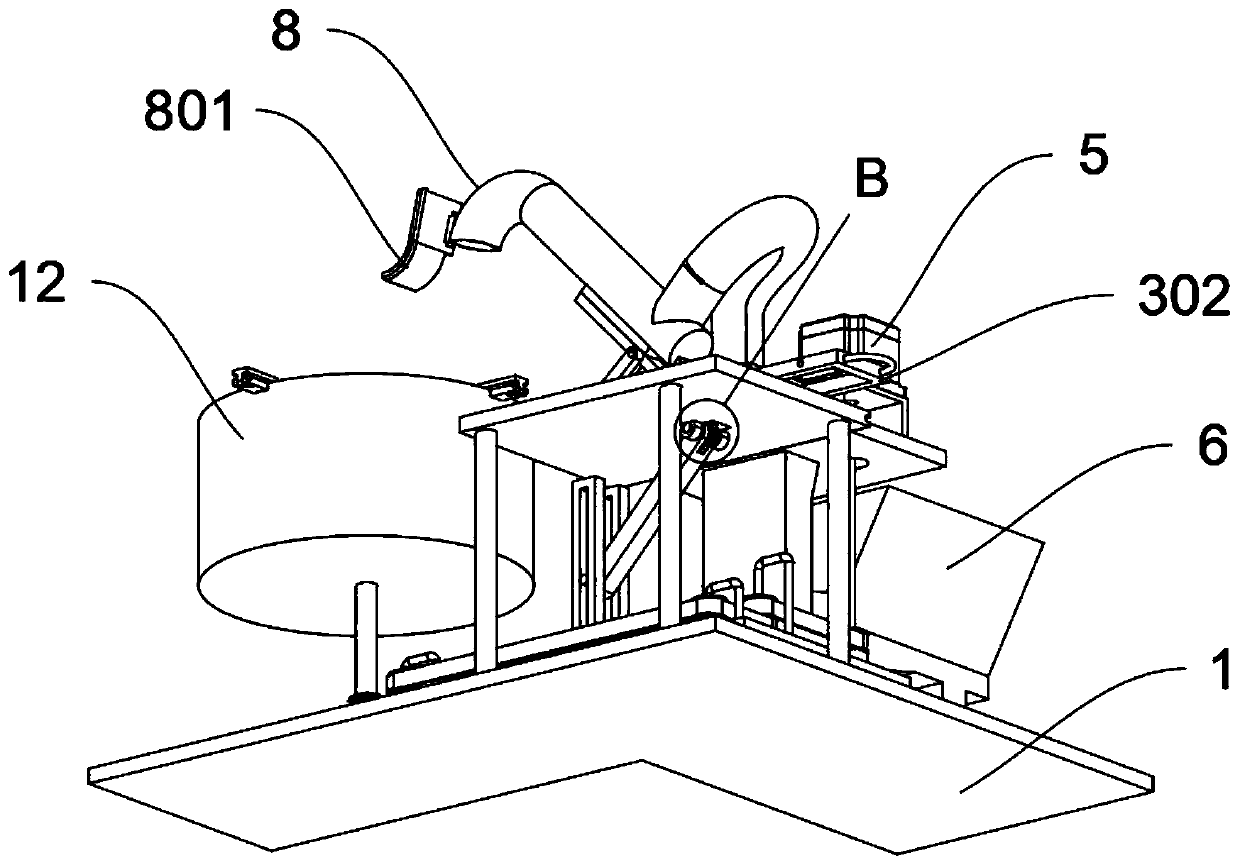

[0033] see Figure 1 to Figure 3 and Figure 5 to Figure 8 , an embodiment provided by the present invention: an automatic device for making an aluminum pot mold shell, including a bottom plate 1; the top of the bottom plate 1 is connected with a top plate 2 through a column; wherein, the middle of the top plate 2 is provided with an upward rotation through a rotating shaft. The rod 9 and the lower rotating rod 10, and the upper rotating rod 9 and the lower rotating rod 10 are all connected by a key to set the gear 11 to rotate synchronously; the top of the upper rotating rod 9 is fixed with a delivery pipe 8 by bolts, and the flexible pipe 602 passes through the clamp The seal is arranged on the top side of the rear end of the delivery pipe 8; wherein, the delivery pipe 8 includes a smear plate 801, the smear plate 801 is an arc-shaped structure and a strip-shaped hole is opened on one side, and the smear plate 801 can be fixed on the delivery pipe by bolts. The outer end of...

Embodiment 2

[0036] On the basis of Example 1, please refer to Figure 1 to Figure 4, a kind of embodiment that the present invention provides: a kind of automation device that is used for the aluminum pan mold shell to make, movable bottom plate 4 includes double-sided synchronous belt 401, transmission synchronous belt 402 and transmission shaft 403; Movable bottom plate 4 top moves through rotating shaft There are three sets of single-layer synchronous wheels and one set of two-layer synchronous wheels, and a double-sided synchronous belt 401 is arranged outside the synchronous wheels; a transmission shaft 403 is arranged on the top of the movable bottom plate 4 through bearing activities, and a synchronous belt is arranged on the outside of the transmission shaft 403 to cooperate with the transmission The synchronous belt 402 is kinematically connected with the two-layer synchronous wheels; the top of the movable bottom plate 4 is integrally provided with a vertical rod structure and is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com