Method and grinding machine for controlling process during grinding of workpiece

A workpiece and grinding technology, applied in the control of workpiece feed movement, automatic grinding control device, program control, etc., to achieve the effects of reducing deformation, reducing error rate, and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

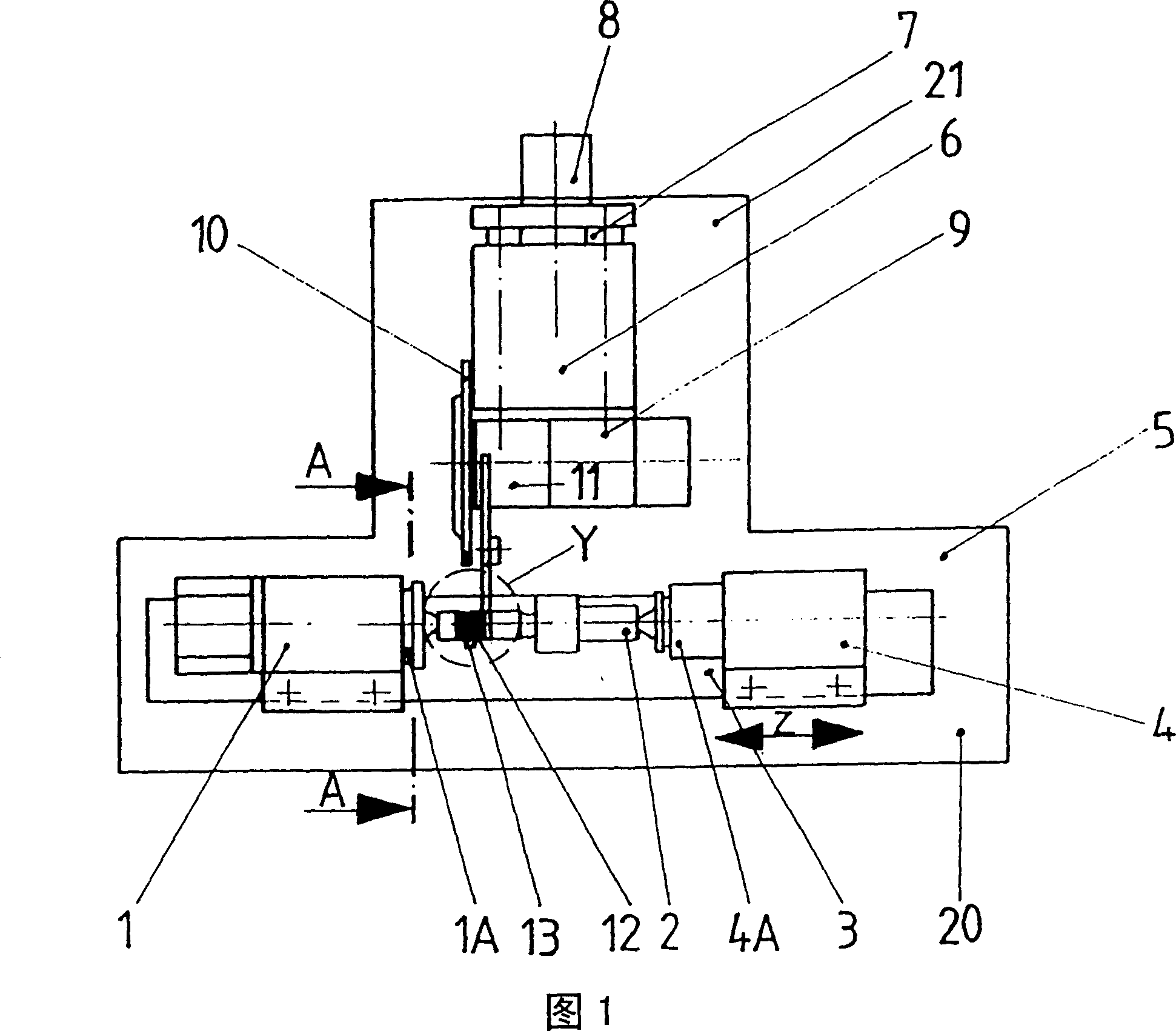

[0021] Fig. 1 is a schematic top view of a cylindrical grinder, which works according to a rough grinding method (longitudinal grinding method). When applying this grinding method, a CBN-grinding wheel with a wear-resistant bond is used. The characteristic of the rough grinding process is that all the grinding allowance can be ground off in one pass by the longitudinal grinding method. The radial feed during grinding is equal to the radial grinding allowance on the workpiece 2 . The known grinding machine has a workpiece headstock 1 with a workpiece spindle 1A, a table 3 and a tailstock 4 with a hydraulically displaceable tailstock sleeve 4A, which is arranged on a bed 5 . The workbench 3 is arranged on the guide rail in the front section 20 of the bed 5, and the workbench runs along the axial direction of the CNC-axis Z on the guide rail. The motor drive for this shaft is not shown in the figure. The workpiece spindle seat 1 with the workpiece spindle 1A arranged on the wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com