Bullet core preparation method and composite bullet core

A composite bullet and bullet core technology, applied in the direction of ammunition, warhead, offensive equipment, etc., can solve the problems of the penetration of armor-piercing bullets to be improved, the density of tungsten alloy is not high enough, human body damage, etc., to improve the penetration performance, and the preparation method is simple. , the effect of enhancing the structural density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

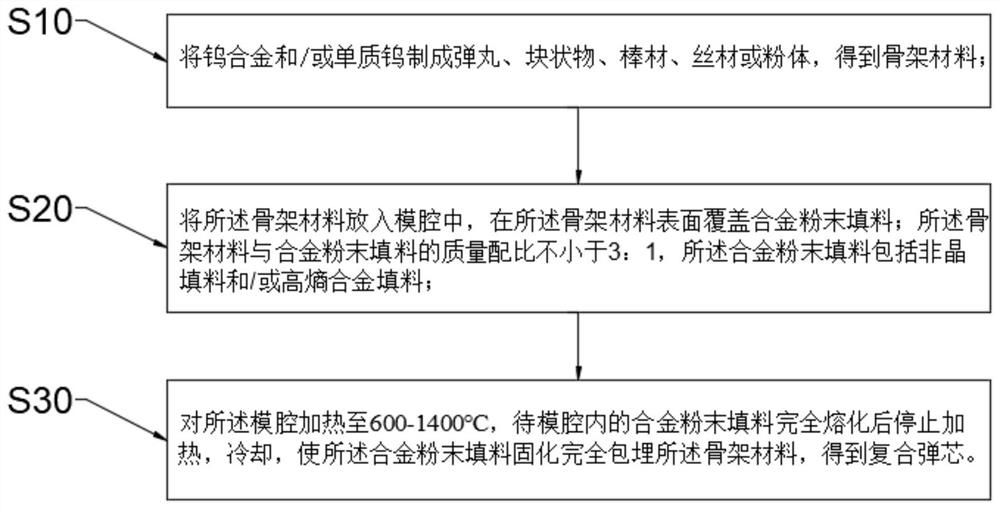

[0032] Such as figure 1 Shown, a kind of core preparation method comprises the following steps:

[0033] S10: Making tungsten alloy and / or elemental tungsten into projectiles, blocks, rods, wires or powders to obtain skeleton materials;

[0034] S20: Put the framework material into the mold cavity, and cover the surface of the framework material with alloy powder filler; the mass ratio of the framework material to alloy powder filler is not less than 3:1, and the alloy powder filler includes amorphous fillers and / or high-entropy alloy fillers;

[0035] S30: After evacuating the mold cavity, heat to 600-1400°C, stop heating after the alloy powder filler in the mold cavity is completely melted, and cool down, so that the alloy powder filler is solidified and completely embeds the skeleton material to obtain a composite core.

[0036] In detail, in this embodiment, the mold cavity has a spherical or spherical structure, the mass ratio of the skeleton material to the alloy powd...

Embodiment 2

[0041] The composite elastic core of this embodiment is prepared by the above-mentioned elastic core preparation method, and the difference from the above-mentioned embodiment 1 is:

[0042] In this embodiment, the framework material is elemental tungsten.

[0043] All the other reaction conditions, steps and factors are the same as in Example 1.

Embodiment 3

[0045] The composite elastic core of this embodiment is prepared by the above-mentioned elastic core preparation method, and the difference from the above-mentioned embodiment 1 is:

[0046] The mass ratio of the skeleton material to the alloy powder filler is 3:1.

[0047] All the other reaction conditions, steps and factors are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com