Patents

Literature

49results about How to "Reduce reaction exotherm" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

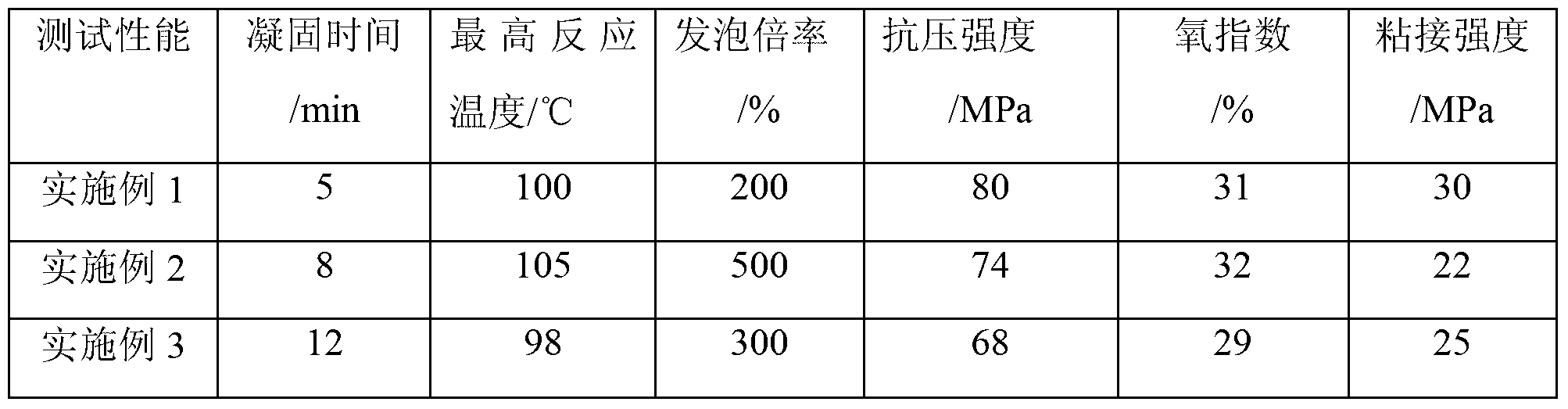

High-strength low-heat-release mining flame-retardant grouting reinforcement material and preparation method thereof

The invention discloses a high-strength low-heat-release mining flame-retardant grouting reinforcement material and a preparation method thereof. The flame-retardant grouting reinforcement material is obtained through mixing and solidifying a component A and a component B which are two low-viscosity liquids, the component A is obtained through mixing 60-80 parts of an isocyanate prepolymer, 10-38 parts of a flame retardant and 2-3 parts of an antistatic agent, and the component B is obtained through mixing 30-40 parts of polyether polyol, 0.1-0.5 parts of a catalyst, 10-25 parts of a diluting agent, 10-30 parts of an epoxy resin and 10-25 parts of a phenolic resin. The flame-retardant grouting reinforcement material has a low reaction heat release during solidification and has a highest reaction temperature of below 110DEG C, the obtained reinforcement has a high strength and a good caking property with coal rocks, the bonding strength, the sand consolidating strength and the compressive strength of the material are not below 30MPa, not below 8MPa and not below 60MPa, and the grouting reinforcement material has an obviously higher flame retardation property than a simple polyurethane grouting material.

Owner:ANHUI UNIVERSITY +2

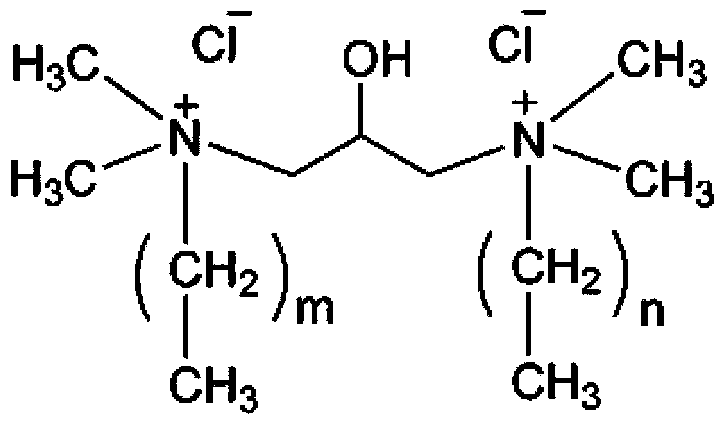

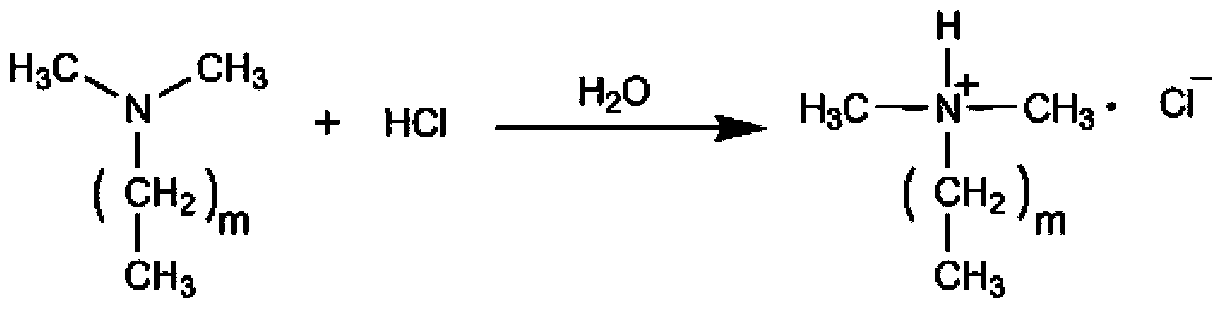

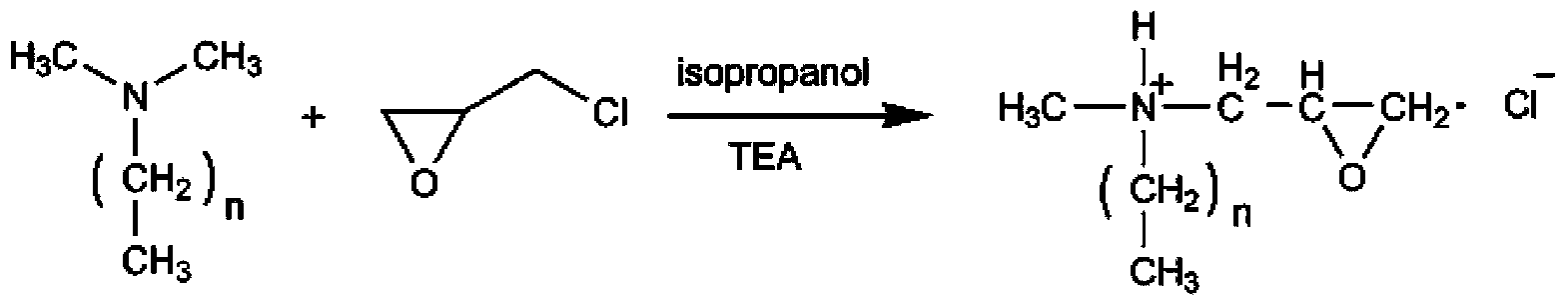

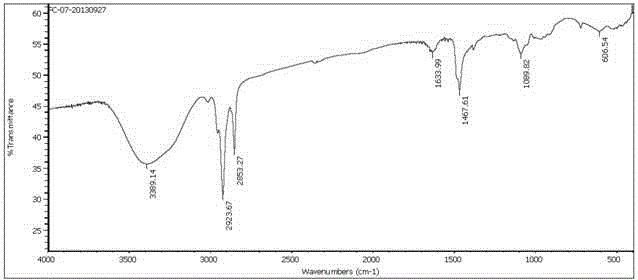

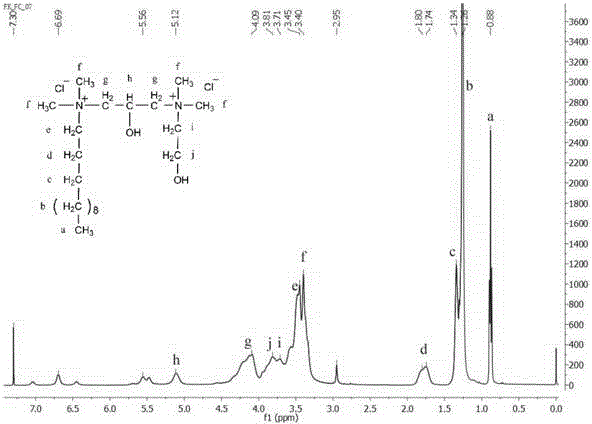

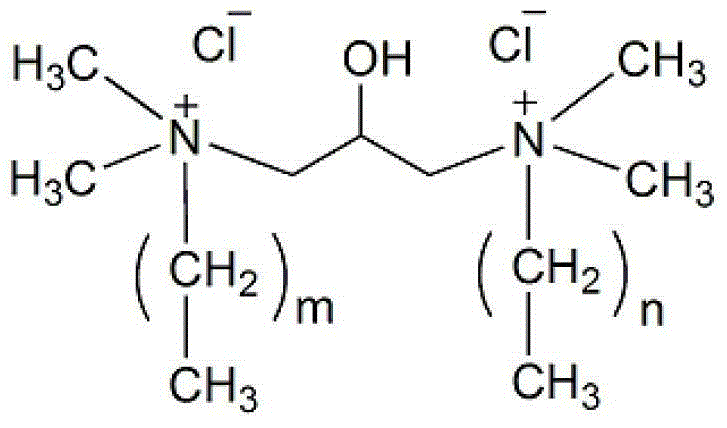

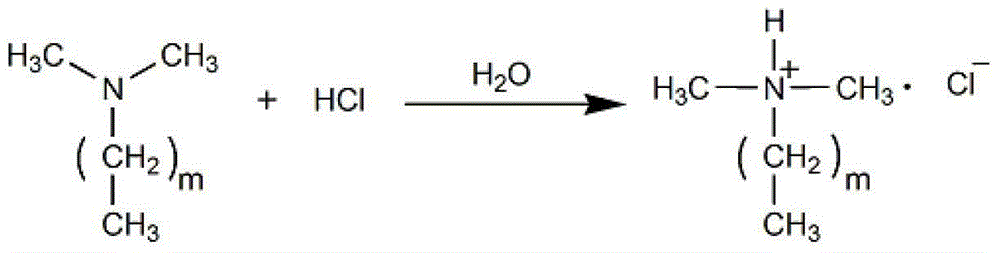

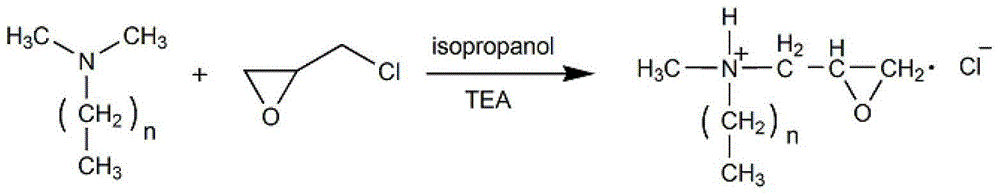

Cationic gemini surfactant preparation method

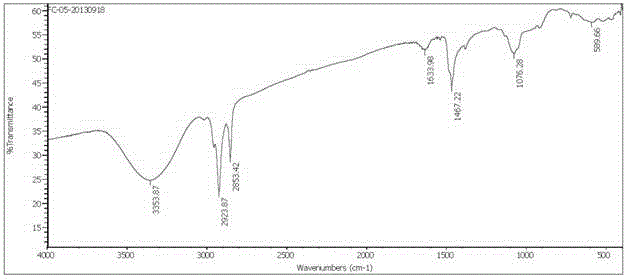

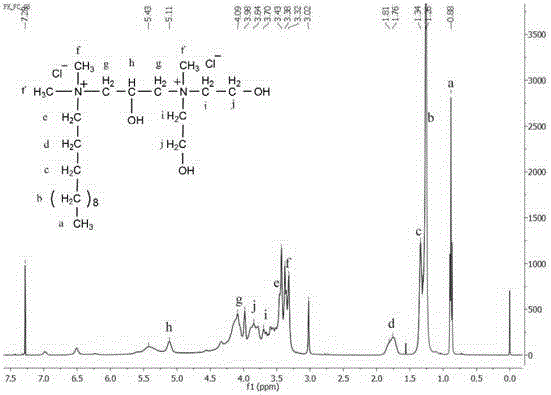

ActiveCN103406063AReduce special requirementsReduce reaction exothermOrganic compound preparationTransportation and packagingEpichlorohydrin1-Chloropropane

The invention belongs to the technical field of surfactants, and provides a method for preparing a cationic gemini surfactant (CH3(CH2)m-N(CH3)2-CH2CH(OH)CH2-N(CH3)2(CH2)nCH3.Cl2) by taking epoxy chloropropane and alkyl dimethyl tertiary amine (CH3-(CH2)n-N(CH3)2, wherein n equals to 7, 9, 11, 13, 15 or 17) as raw materials and taking 2-hydroxyl-1.3-propylidene as a linking group. The method provided by the invention overcomes the defect in the prior art that one extremely excessive material is required for improving the reaction yield, dispenses with separation and purification procedures for a finished product, is short in reaction period, leaves no epoxy chloropropane in the finished product, and is suitable for industrial scale production.

Owner:SHANGHAI FINE CHEM CO LTD +1

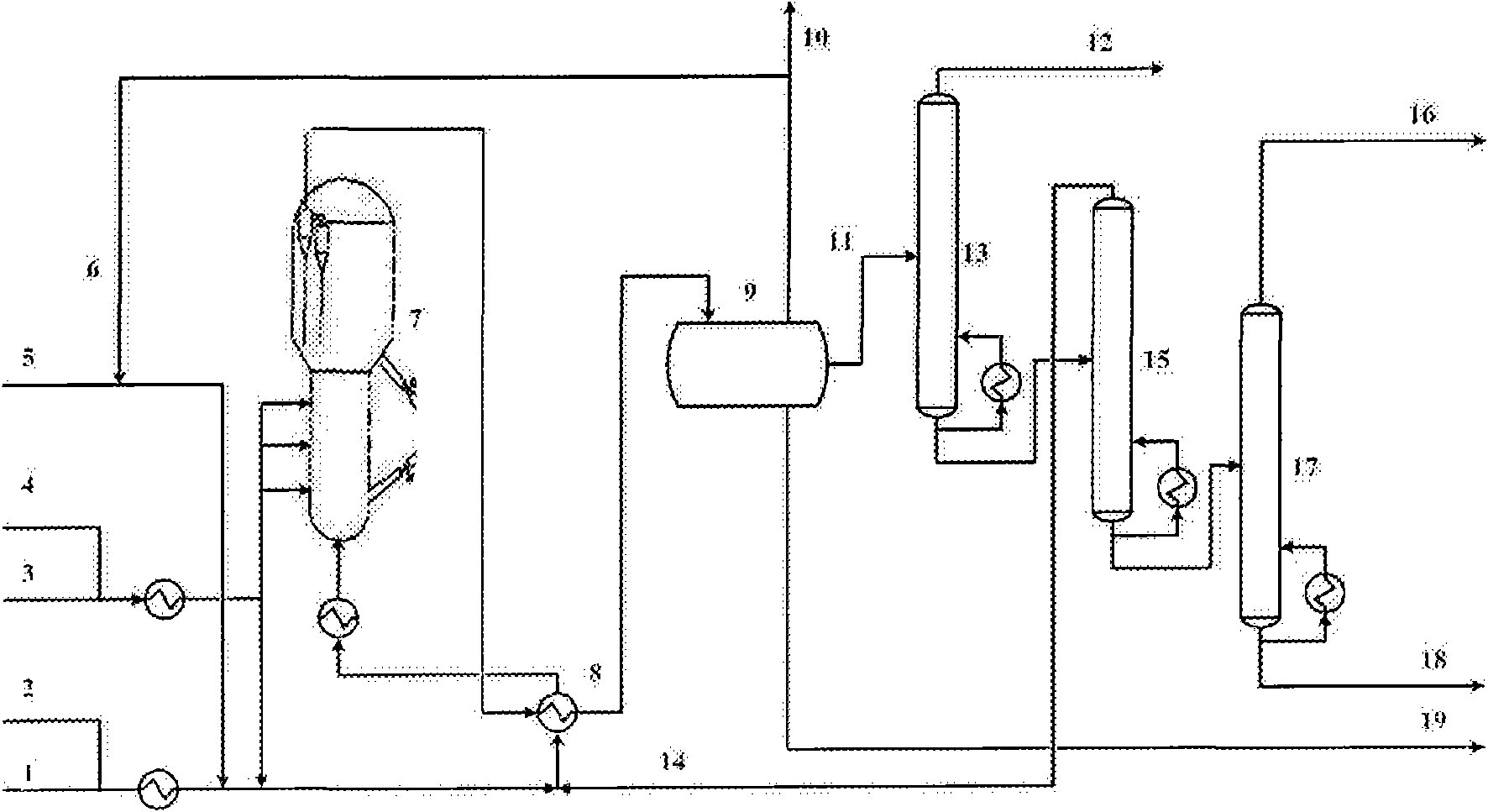

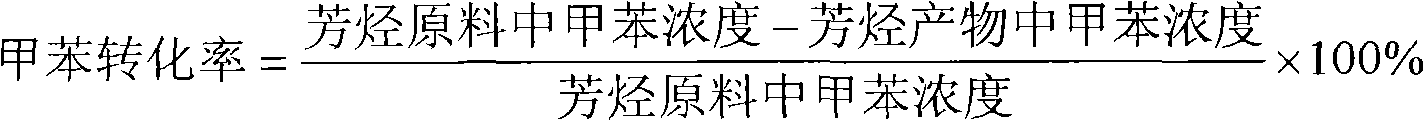

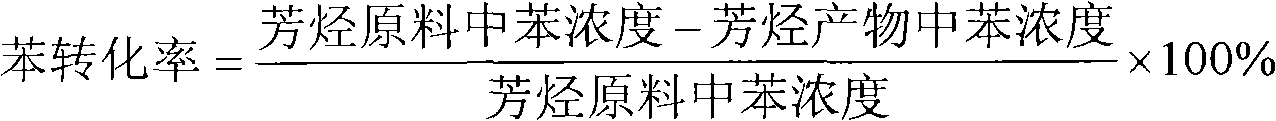

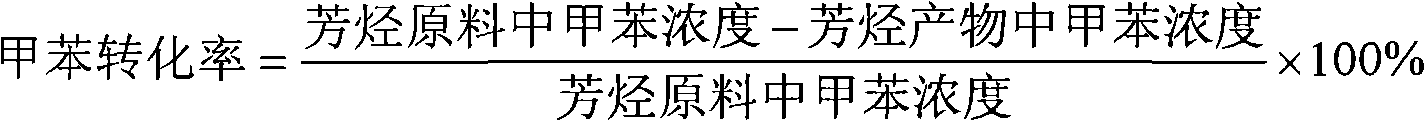

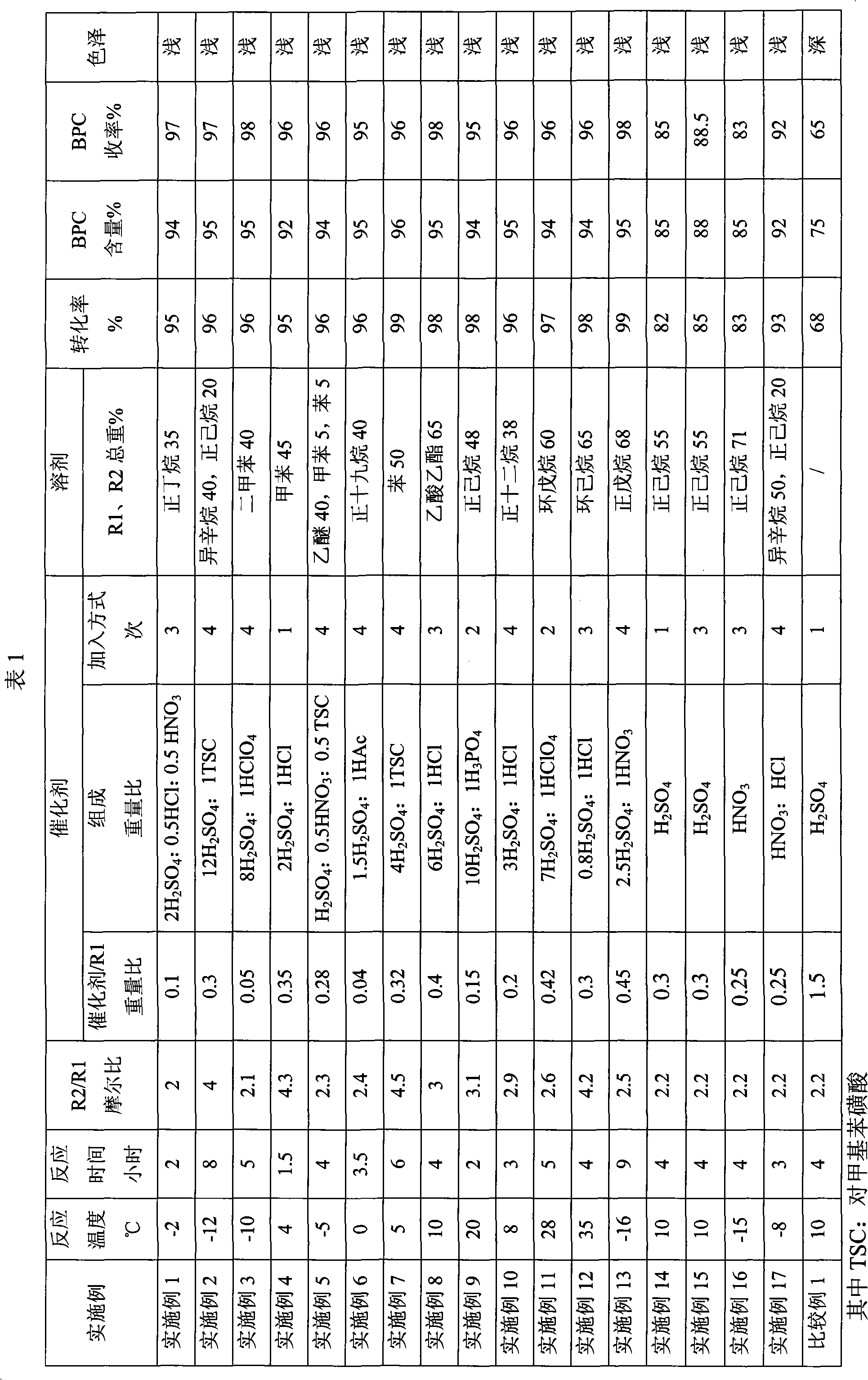

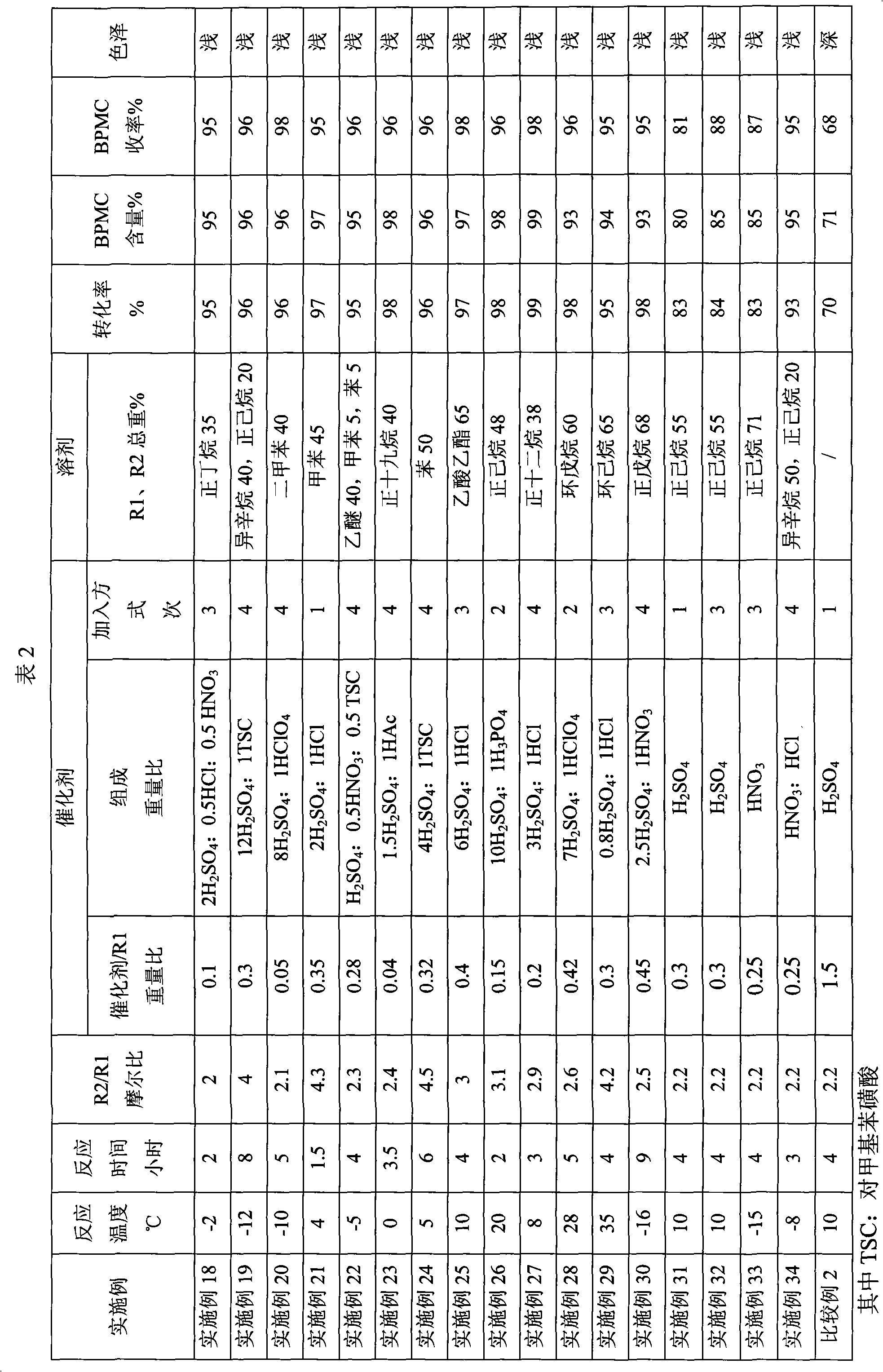

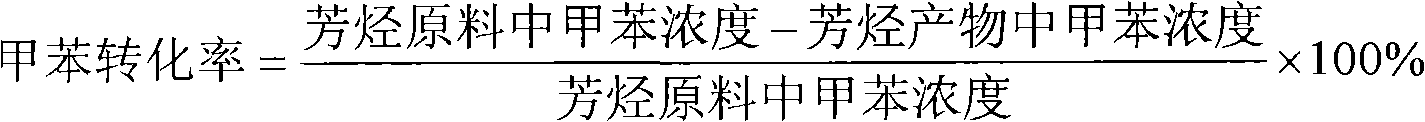

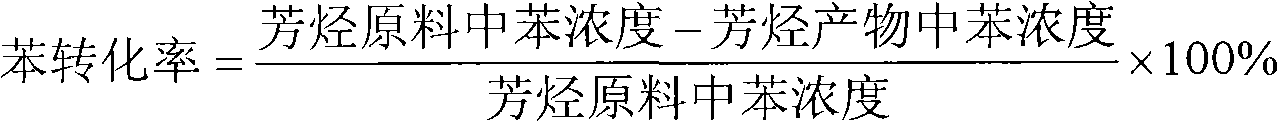

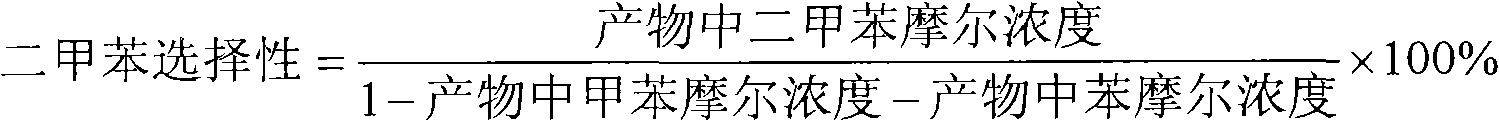

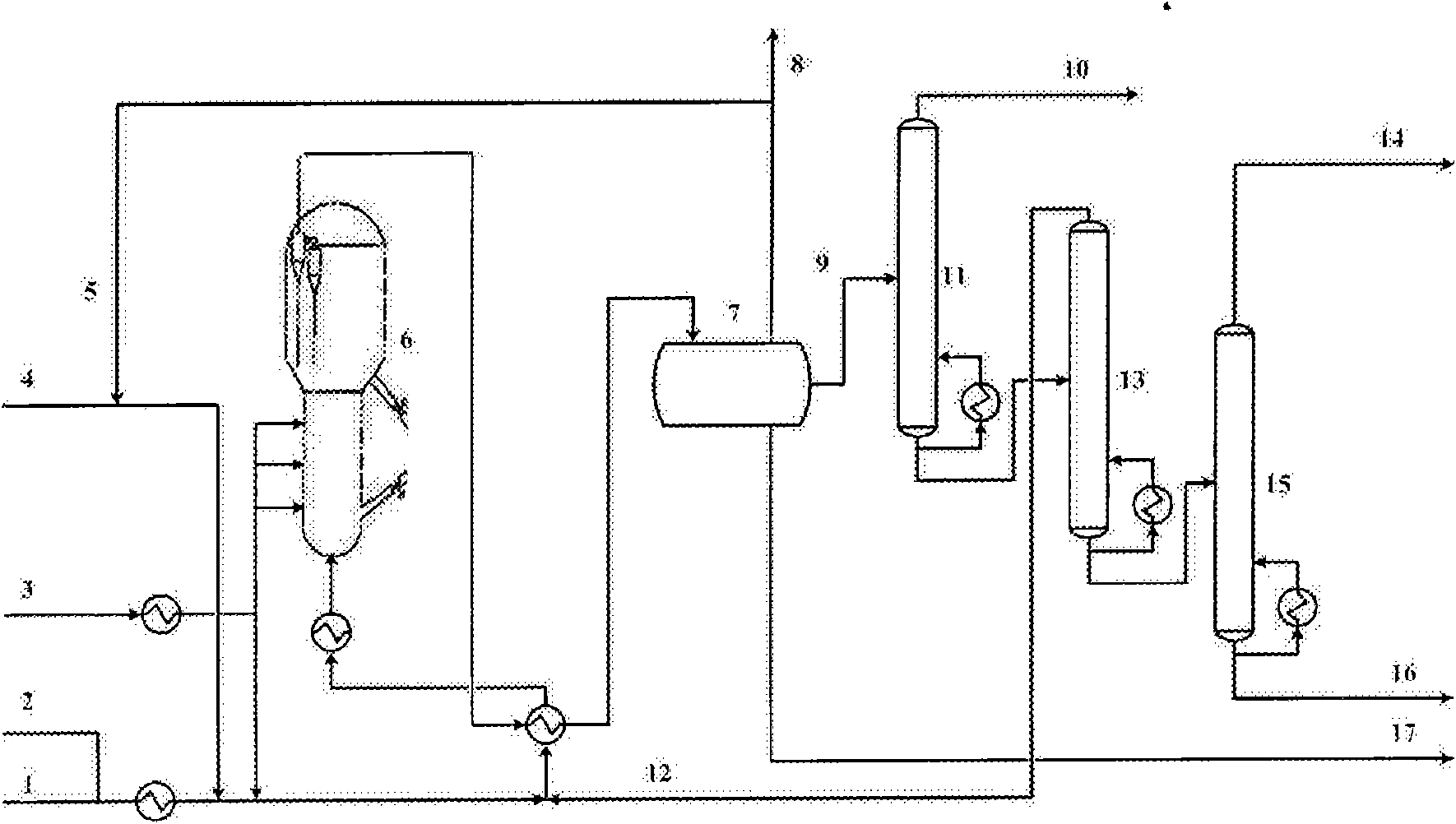

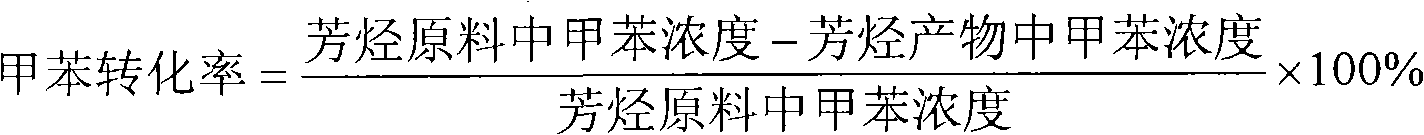

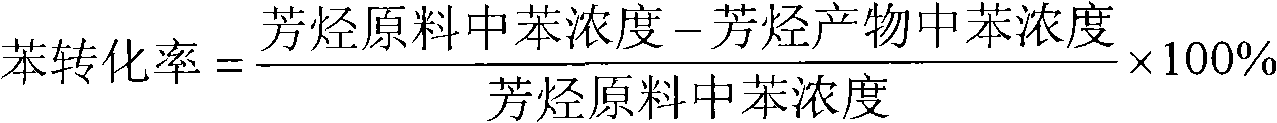

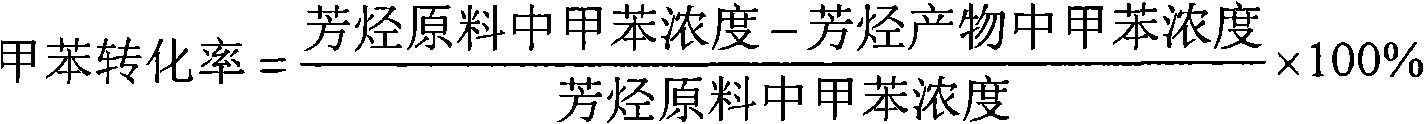

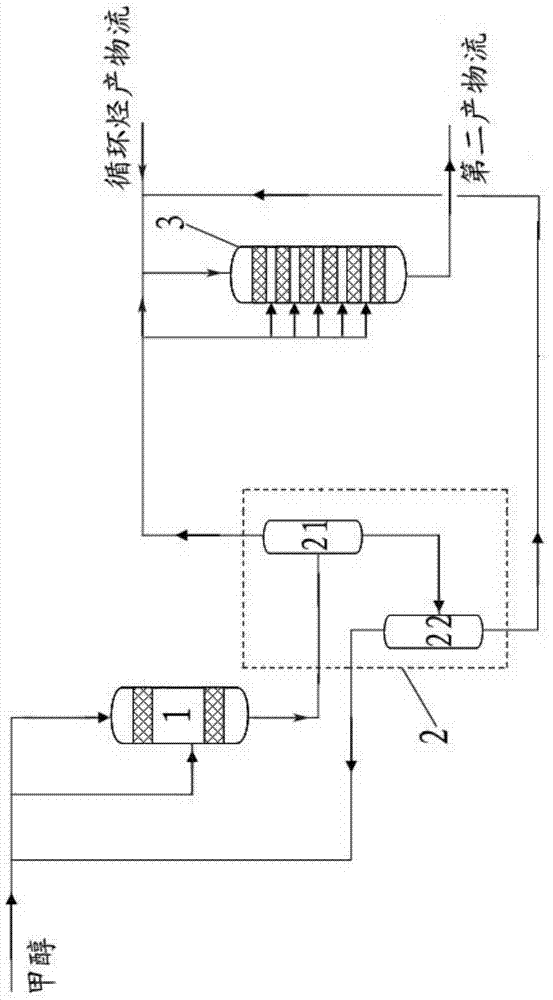

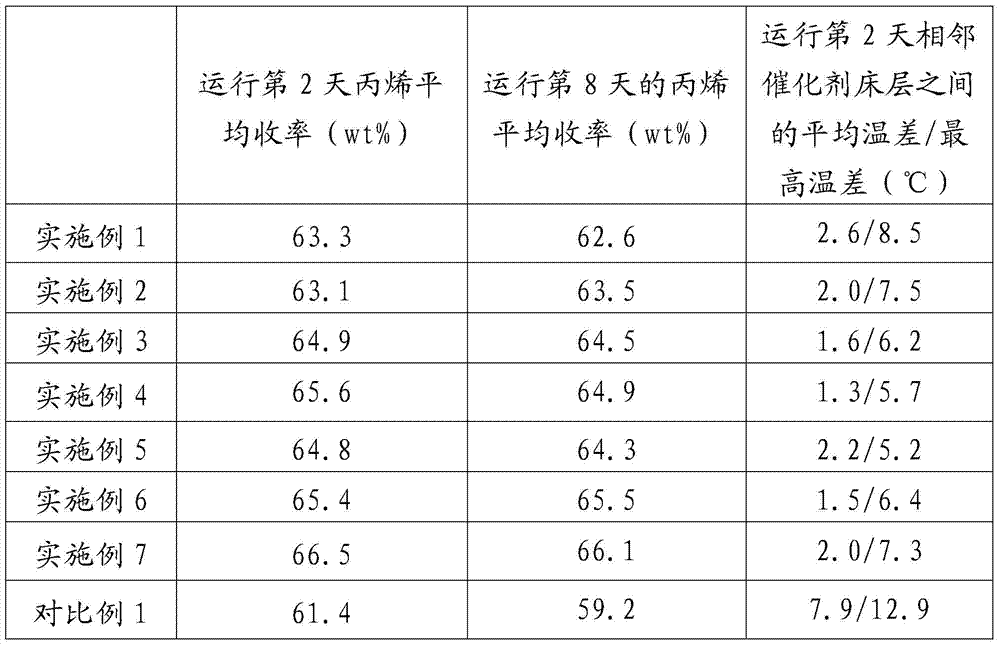

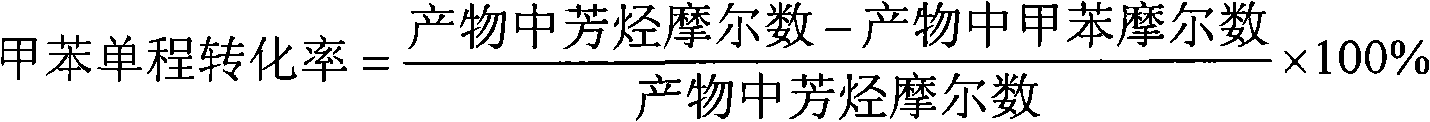

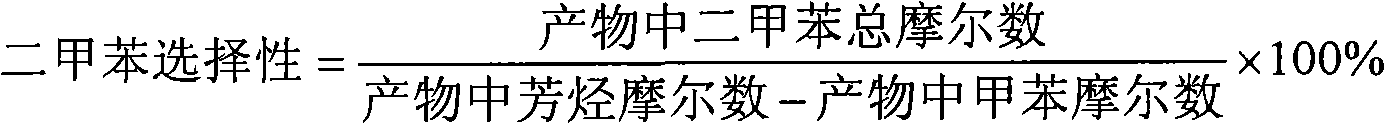

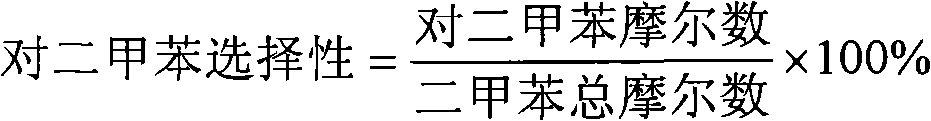

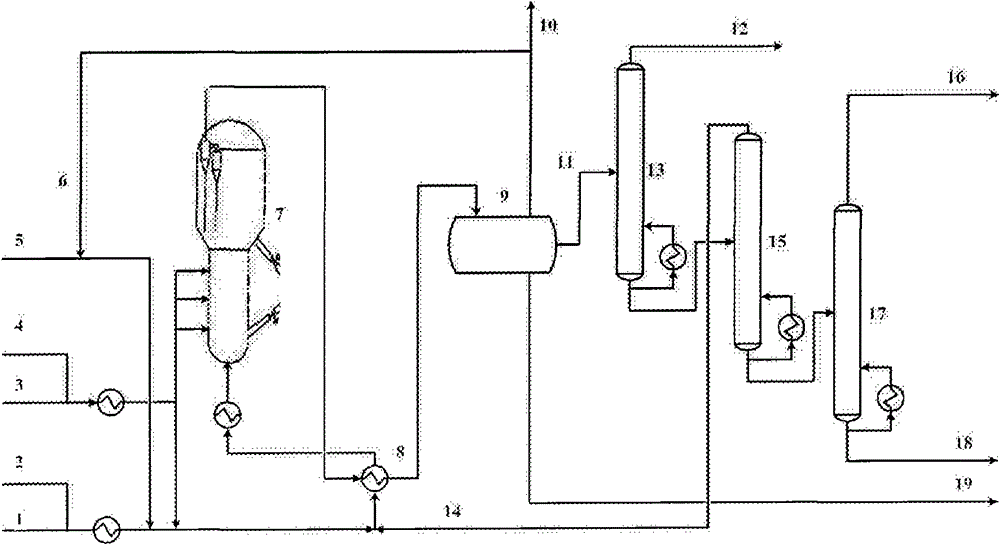

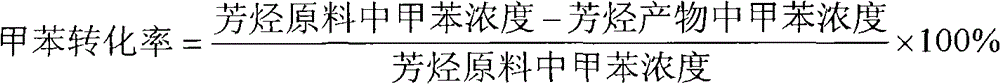

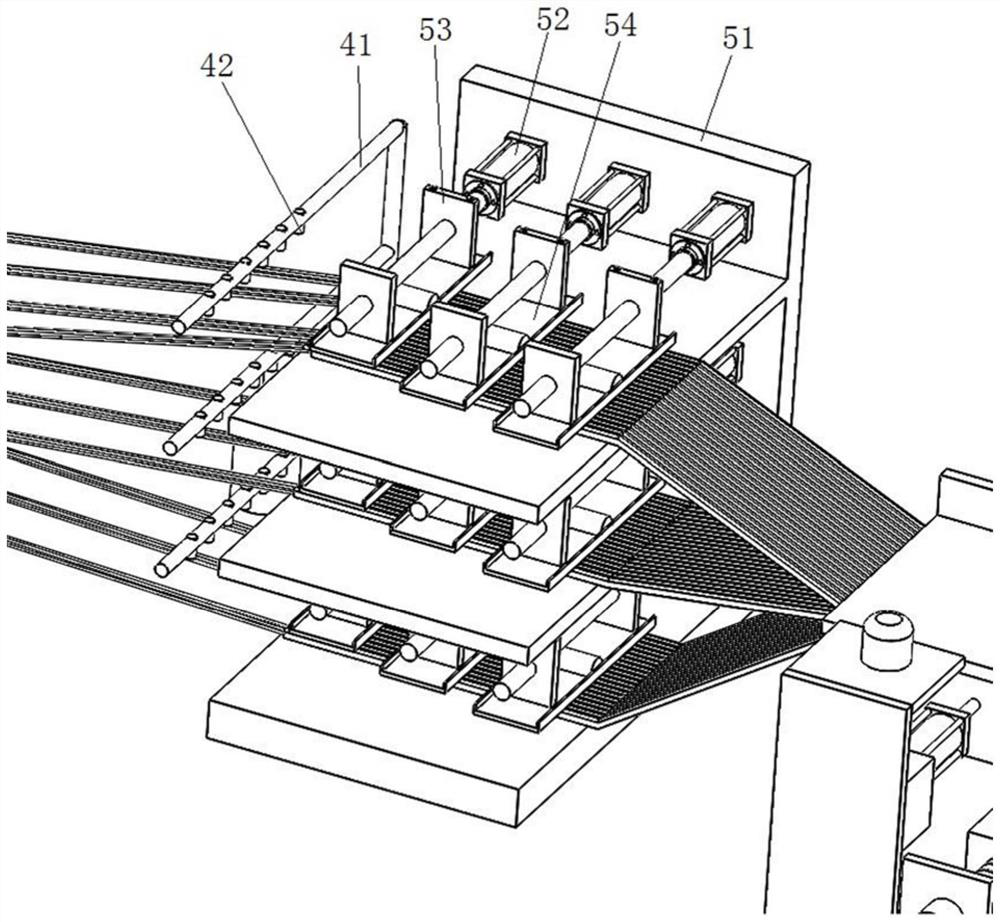

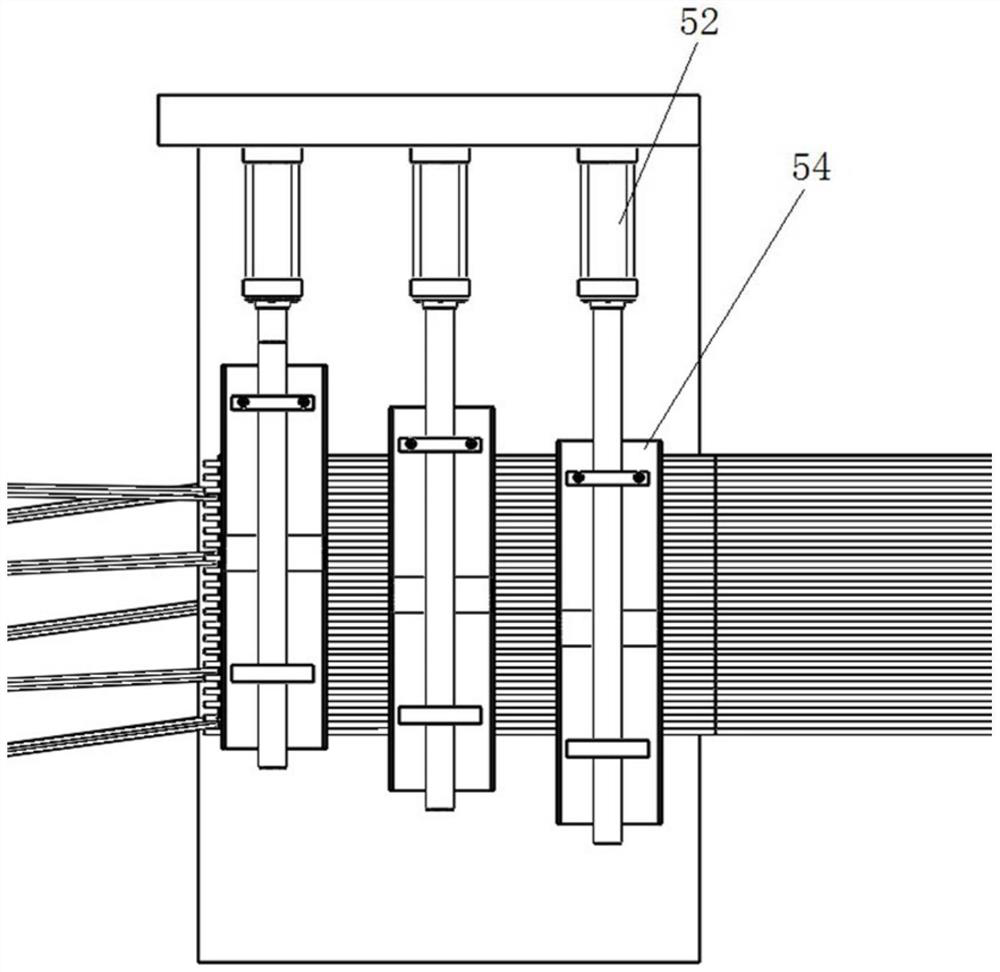

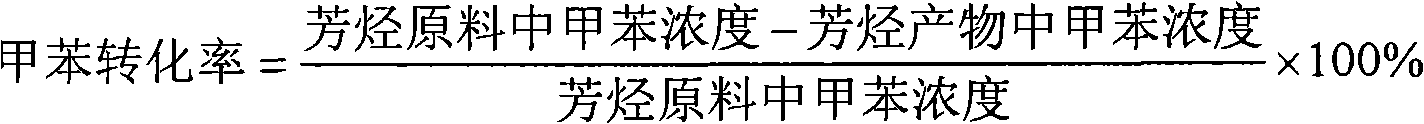

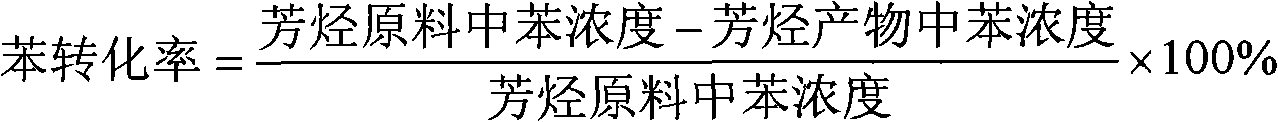

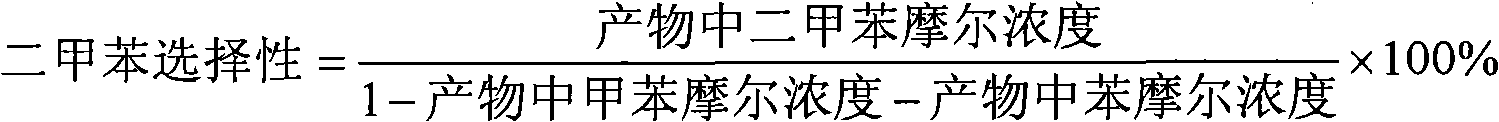

Method for preparing fluidized bed of para-xylene by aromatics alkylation

ActiveCN102372585AHigh selectivityControl feed temperatureHydrocarbon by hydrocarbon and non-hydrocarbon condensationChemical/physical processesAlkyl transferHydrogen

The invention relates to a method preparing a fluidized bed of para-xylene by aromatics alkylation, which mainly solves the problems of single raw material, large temperature increase of a reaction bed layer, poor catalyst stability, frequent side reaction of an alkylation reagent and low utilization rate in the prior art. According to the invention, the method comprises the following steps: mixing and vaporizing benzene and toluene feed to obtain an aromatic mixture I, vaporizing a mixture of methanol or methanol and dimethyl ether to obtain an alkylation reagent feed II; merging 10-90% of alkylation reagent feed II, the aromatic mixture I and hydrogen carrying gas to obtain a reaction mixture III; the rest part of the alkylation reagent feed II forms single stream or a plurality of streams and can be introduced into a reactor from one position or a plurality of positions of the inlet downstream of a fluidized bed reactor. The technical problem better solves the problems, and can be used in the industrial production for preparing para-xylene by aromatics alkylation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Surface treated metal and surface treatment method thereof and metal resin complex and preparation method of metal resin complex

ActiveCN103451701AIncrease corrosion rateReduce corrosion rateAnodisationPore diameterAnodic oxidation

The invention provides a surface treated metal and a surface treatment method thereof and a metal resin complex and a preparation method of the metal resin complex. The surface treated metal comprises a metal body and an anodic oxidation film layer which is located on the surface of the metal body, the anodic oxidation film layer includes a barrier layer which is in contact with the metal body and a loose layer located on the outer surface of the barrier layer, the loose layer contains anodic oxidation film micropores, the pore diameter of the anodic oxidation film micropores is 10 nm-800 mum, the barrier layer contains barrier layer corrosion pores, the pore diameter of the barrier layer corrosion pores is 10 nm-800 mum, the metal body includes a corrosion layer which is in contact with the barrier layer, the corrosion layer contains metal corrosion pores, the pore diameter of the metal corrosion pores is 10 nm-1 mm, the metal is aluminum alloy or aluminum, the bonding force between the metal and resin is strong, and the surface treated metal is simple in process, is easy for large-scale production, and has no pollution.

Owner:BYD CO LTD

Preparation method of metal resin complex and metal resin complex prepared thereby

ActiveCN103451704AReduce reaction exothermImprove bindingSurface reaction electrolytic coatingAlloy substratePhosphoric acid

The invention provides a preparation method of a metal resin complex and the metal resin complex prepared thereby. The preparation method of the metal resin complex comprises the following steps: S1, anodic oxidation: a metal substrate with a surface comprising an anodic oxidation film layer is obtained by anodic oxidation of a pretreated metal substrate, and the metal substrate is an aluminum alloy substrate or aluminum substrate; S2, treatment with phosphoric acid: the metal substrate containing the anodic oxidation film layer and obtained by the step S1 is immersed in a phosphoric acid solution for treatment to obtain a surface treated metal substrate; and S3, injection: the surface of the surface treated metal substrate is injected with a resin composition, and then the metal resin complex is obtained after molding. In the metal resin complex, the binding force between metal and resin is strong, and the process is simple, is easy for large-scale production, and has no pollution.

Owner:BYD CO LTD

Epoxy resin premix and preparation technology of the epoxy resin premix

ActiveCN102181128AMeet the requirements of the resulting environmental protectionLow viscosityEpoxyHeat resistance

The invention discloses an epoxy resin premix which is characterized by containing epoxy resin mixture and curing agent mixture, wherein the epoxy resin mixture includes epoxy resin, color paste, aluminum hydroxide filler and epoxy resin efficient fire retardant and the curing agent mixture includes methyl tetrahydrophthalic anhydride, accelerator and aluminum hydroxide filler. Aiming at solving the problems that in the prior art, epoxy resin is utilized for pouring a dry type transformer, various harmful substances are probably generated and the practical production and application can not be met, the invention provides the epoxy resin premix and a preparation technology of the epoxy resin premix, wherein the epoxy resin premix has low viscosity, a long service cycle, convenience for pouring, small curing shrinkage, property of being not apt to crack, good heat conductivity, good resistance to abrasion, corrosion and heat, high mechanical strength and preferable electrical property. The epoxy resin premix can be used for pouring dry type transformers, current transformers, voltage transformers, insulators, cushion blocks and the like.

Owner:GOODE EIS SUZHOU CORP LTD

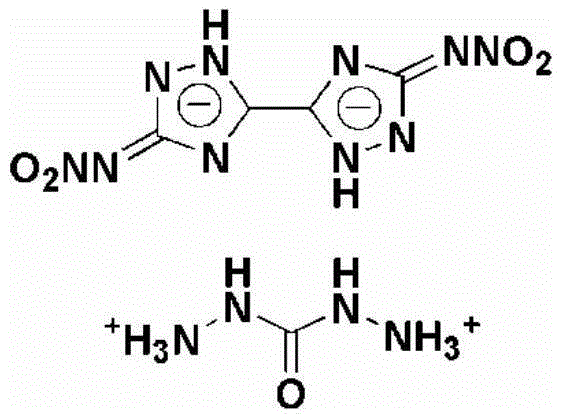

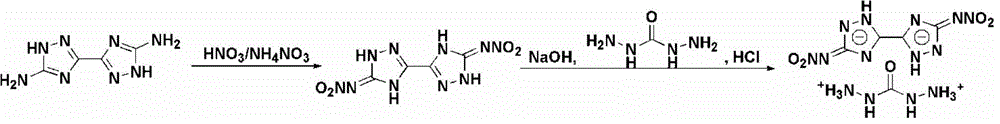

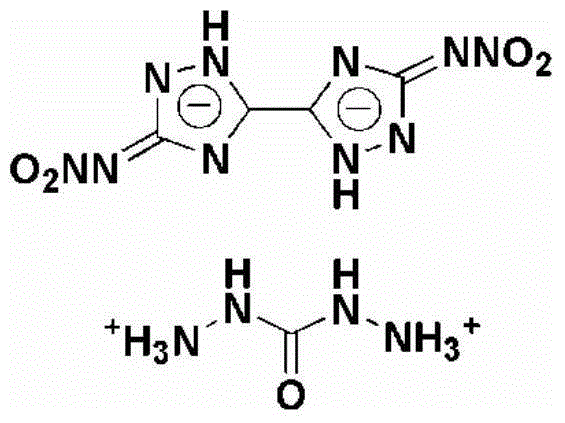

Method for synthesizing 5,5'-dinitroamino-3,3'-co-1,2,4-triazole carbohydrazide

The invention discloses a method for synthesizing 5,5'-dinitroamino-3,3'-co-1,2,4-triazole carbohydrazide. The carbohydrazide has the following structural formula, wherein the structural formula is as shown in the specification. In the method, 5,5'-diamino-3,3'-co-1,2,4-triazole serves as a raw material, and the method comprises the following steps: (1) adding the 5,5'-diamino-3,3'-co-1,2,4-triazole into a nitric acid and ammonium nitrate system in batches at the temperature of 0 DEG C, wherein a molar ratio of the 5,5'-diamino-3,3'-co-1,2,4-triazole, nitric acid to ammonium nitrate is 1:40: (4-8), stirring for 15 minutes, raising the temperature to 25 DEG C, reacting for 1.5 hours, pouring the reaction liquid into ice water, filtering, washing and drying to obtain 5,5'-dinitroamino-3,3'-co-1,2,4-triazole; and (2) adding the 5,5'-dinitroamino-3,3'-co-1,2,4-triazole, an aqueous liquid of sodium hydroxide and carbohydrazide into a reaction bottle under the temperature of 60 DEG C, wherein a molar ratio of the 5,5'-dinitroamino-3,3'-co-1,2,4-triazole, sodium hydroxide to carbohydrazide is 1:3:2.05, stirring for 20 minutes, dropwise adding 35 mass percent of hydrochloric acid until the pH value is 4-7, reducing the temperature to 25 DEG C, separating out a white product 5,5'-dinitroamino-3,3'-co-1,2,4-triazole carbohydrazide in the system. The method is mainly used for preparing the5,5'-dinitroamino-3,3'-co-1,2,4-triazole carbohydrazide.

Owner:XIAN MODERN CHEM RES INST

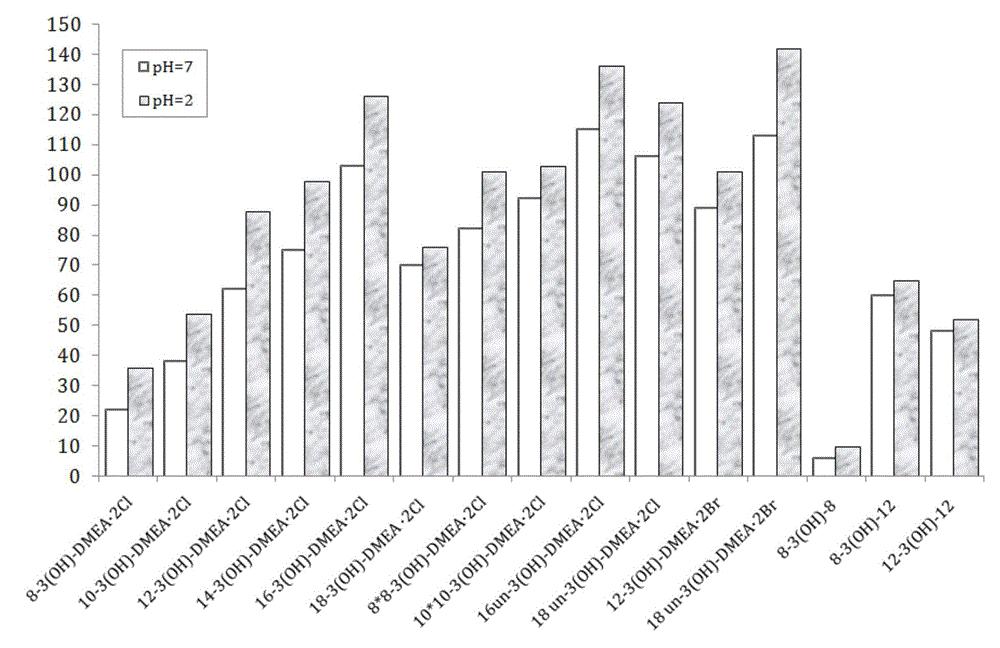

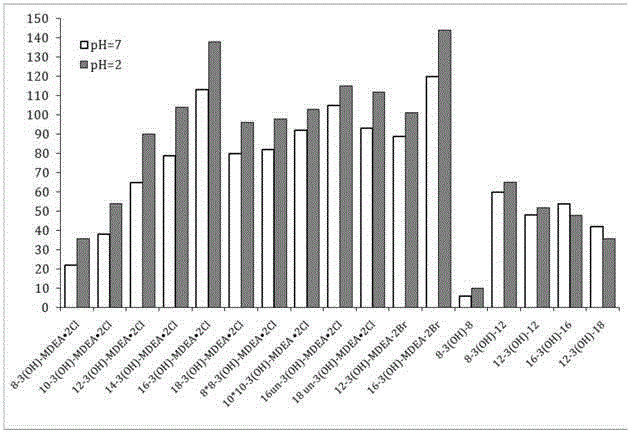

Dissymmetric cationic Gemini surfactant and preparation method thereof

ActiveCN104607094AImprove surface activityGood emulsificationOrganic compound preparationTransportation and packagingAlkaneHydrogen

The invention provides a dissymmetric cationic Gemini surfactant. A molecular structure of the dissymmetric cationic Gemini surfactant is as shown in a formula (IV), wherein X-=Cl- or Br- in the formula, and R1 and R2 in the formula conform to the following (1) or (2): (1) R1=-CH3, and R2 is long-chain alkane base-CnH2n+1, n=6-20; or R2 is long-chain olefin base-CnH2n, n=6-20; and (2) R1=R2=long-chain alkane base-CnH2n+1, n=6-12. According to the surfactant provided by the invention, a molecule of the surfactant contains two -OH groups, and in an aqueous solution, especially under the acidic condition, due to hydrogen-bonding action, molecules are arranged more closely when being enriched on a surface or an interface. Therefore, the series of dissymmetric cationic Gemini surfactant has excellent surface activity, foaming and foam stability, and emulsifying property. Especially under the acidic condition, the emulsifying stability is improved substantially.

Owner:SHANGHAI FINE CHEM CO LTD

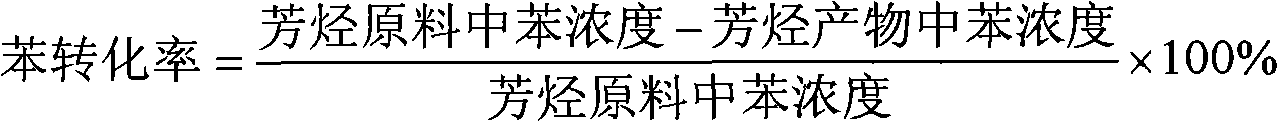

Fluidized catalytic method for preparing p-xylene by alkylating aromatic hydrocarbon

ActiveCN102372584AReduce temperature riseDelay inactivationHydrocarbon by hydrocarbon and non-hydrocarbon condensationXylyleneBenzene

The invention relates to a fluidized catalytic method for preparing p-xylene by alkylating aromatic hydrocarbon. By the fluidized catalytic method, the problems of single raw materials, high temperature rise of a reaction bed, poor stability of a catalyst, multiple side reactions of an alkylating reagent and a low utilization rate in the prior art are mainly solved. In the fluidized catalytic method, methanol, dimethyl ether, benzene and toluene are subjected to mixed feeding, and the dimethyl ether is used as the alkylating reagent. Through the technical scheme, the problems are better solved. The fluidized catalytic method can be applied to industrial production of the p-xylene by performing alkylation reaction on the aromatic hydrocarbon.

Owner:CHINA PETROLEUM & CHEM CORP +1

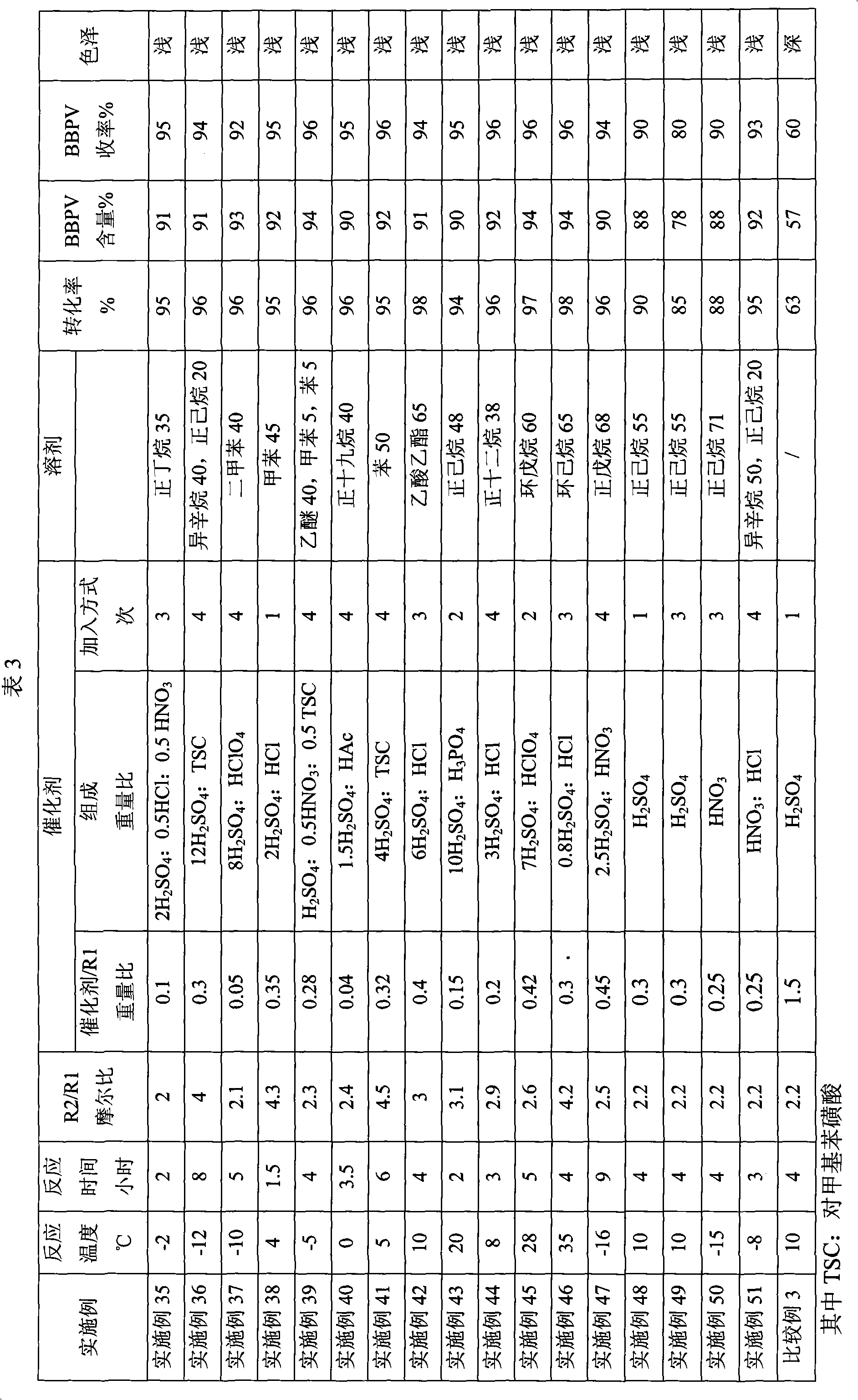

Production method of di(tert-butylperoxy)ketal

ActiveCN102336695AReduce dosageSmooth responseOrganic compound preparationPeroxy compound preparationCyclohexanoneReaction temperature

The invention relates to a production method of di(tert-butylperoxy)ketal, and mainly solves the problems of low product content, low yield, deep color and low production safety caused by violent side reaction in the previous technique. In the invention, R1 selected from cyclohexanone, 3,3,5-trimethylcyclohexanone or butyl levulinate and R2 tert-butyl hydroperoxide, which are used as raw materials, react in the presence of solvent at -20-40 DEG C under normal pressure for 0.5-10 hours to obtain the corresponding product 1,1-di(tert-butylperoxy)cyclohexane, 1,1-di(tert-butylperoxy)-3,3,5-trimethylcyclohexanone or 4,4,-di(tert-butylperoxy)-n-butyl valerate, wherein the mol ratio of R2 to R1 is (2-10):1, the weight ratio of solvent to R1 is (0.01-0.50):1, and the amount of the solvent accounts for 20-80% of the total weight of the reactants R1 and R2; and the catalyst is selected from at least one of sulfuric acid, phosphoric acid, hydrochloric acid, perchloric acid, p-methylbenzenesulfonic acid, nitric acid or acetic acid. The technical scheme provided by the invention solves the problems in the previous technique, and can be used for industrial production of di(tert-butylperoxy)ketal.

Owner:CHINA PETROCHEMICAL CORP

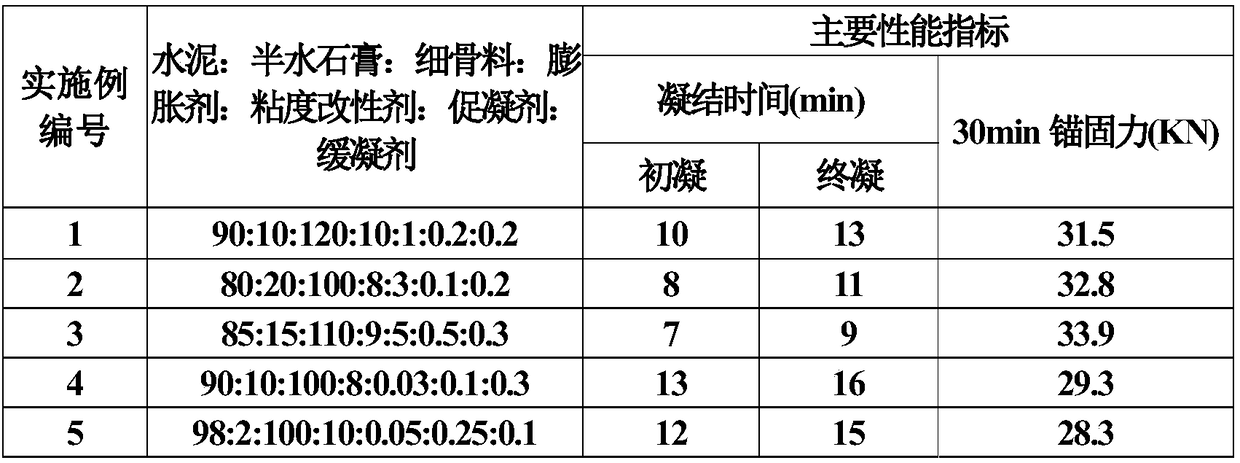

Blast hole filling material and preparation method thereof, and blast hole filling method

InactiveCN109384435AEasy to insertReduce reaction exothermBlastingHand operationsConstruction aggregate

The invention provides a blast hole filling material and a preparation method thereof, and a blast hole filling method, wherein the blast hole filling material comprises, by mass, 100 parts of a cementing material, 50-200 parts of fine aggregate, 5-10 parts of a swelling agent, 0.01-5 parts of a viscosity modifier, 0.01-1 part of a coagulant, and 0-1 part of a retarder. According to the present invention, the blast hole filling material provided by the embodiments has characteristics of no stirring, easy insertion, low reaction heat emission, rapid hardening, high blocking force and the like;and the preparation method and the blast hole filling method are simple and feasible, and can achieve manual one-hand operation, shorten the filling time, and improve the construction efficiency.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

A kind of preparation method of cationic gemini surfactant

ActiveCN103406063BReduce special requirementsReduce reaction exothermOrganic compound preparationTransportation and packagingSURFACTANT BLENDIndustrial scale

The invention belongs to the technical field of surfactants. The invention provides a method using epichlorohydrin and alkyl dimethyl tertiary amine (CH3-(CH2)n-N(CH3)2, n=7, 9, 11, 13, 15, 17) as raw materials, with 2 Preparation of a series of cationic gemini surfactants CH3(CH2)mN(CH3)2-CH2CH(OH)CH2-N(CH3)2(CH2)nCH3·Cl2 with -hydroxyl-1,3-propylene as linking group method. The method of the present invention overcomes the defect that a large excess of one material must be used to increase the reaction yield in the prior art, and the separation and purification step of the finished product can be omitted, the reaction cycle is short, the finished product has no epichlorohydrin residue, and is suitable for industrial scale production .

Owner:SHANGHAI FINE CHEM CO LTD +1

Method for producing silicone oil with high hydrogen content by methyldichlorosilae through solvent-free hydrolysis

The invention relates to a method for producing silicone oil with high hydrogen content by methyldichlorosilae through solvent-free hydrolysis. The method is characterized by comprising the following steps: adding methyldichlorosilae, trimethylchlorosilane and an organosilicone protecting agent into a reaction kettle, starting stirring and introducing nitrogen gas; continuously feeding domestic water to the reaction kettle, starting a liquid ring compressor, exhausting generated hydrogen chloride away, feeding the hydrogen chloride to a high boiling point cracking device, controlling the temperature in the reaction to be -50 DEG C to 15 DEG C, controlling the temperature of the reaction kettle to be below 15 DEG C after the domestic water is completely fed, reacting for 1 hours, and discharging 21-25% hydrochloric acid at the lower layer after standing and layering; transferring hydrolysate on the upper layer to a deacidification kettle, adding an adsorbent, and stirring for 1 hour to deacidify; taking supernatant liquid and adding into a telomerization kettle, adding activated clay, controlling the temperature to 55-75 DEG C, reacting for 3-6 hours, and filtering to obtain a hydrogen-containing silicone oil; and distilling the hydrogen-containing silicone oil in a distillation kettle, controlling the vacuum degree to -0.09 to 0.01Mpa and the temperature to 115-130 DEG C, and removing low molecules to obtain the hydrogen-containing silicone oil finished-product.

Owner:吉林东湖有机硅有限公司

Fluidized catalytic method of p-xylene by methylation of aromatic hydrocarbon

ActiveCN102372586AReduce temperature riseDelay inactivationHydrocarbon by hydrocarbon and non-hydrocarbon condensationBulk chemical productionCatalytic methodAromatic hydrocarbon

The invention relates to a fluidized catalytic method of p-xylene by methylation of aromatic hydrocarbon, and mainly solves the problems of high temperature rise of a reaction bed, poor catalyst stability, more side reaction of an alkylation reagent and low utilization rate in the prior art. According to the technical scheme, dimethyl ether and aromatic hydrocarbon are used as mixing feeds and dimethyl ether is used as the methylation reagent. The technical scheme greatly solves the problems and can be applied in the industrial production of p-xylene by methylation reaction of aromatic hydrocarbon.

Owner:CHINA PETROLEUM & CHEM CORP +1

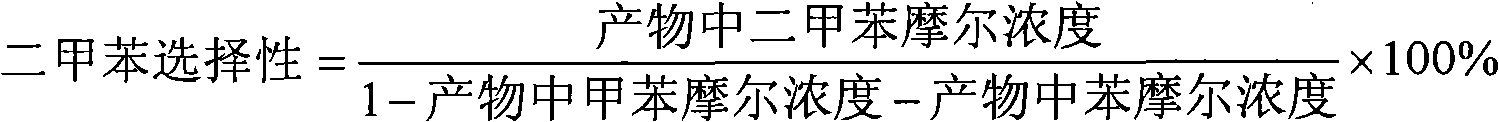

Fluidized bed method for arene methylation

InactiveCN102372587AReduce temperature riseControl temperature riseHydrocarbon by isomerisationHydrocarbon by hydrocarbon and non-hydrocarbon condensationAlkyl transferFluidized bed

The invention relates to a fluidized bed method for arene methylation and mainly solves problems of large temperature rise of a reaction bed layer, weak stability of a catalyst, several side reactions of an alkylation reagent and low utilization rate of a prior art. According to the invention, mixed feeding of part of dimethyl ether and arene is employed; and remaining dimethyl ether feeding, in form of one stream or a plurality of streams, is introduced into a reactor from one or a plurality of positions at a downstream of a fluidized bed reactor inlet. The above technical scheme well solves the problems and can be applied to industrial production of preparation of paraxylene through an arene methylation reaction.

Owner:CHINA PETROLEUM & CHEM CORP +1

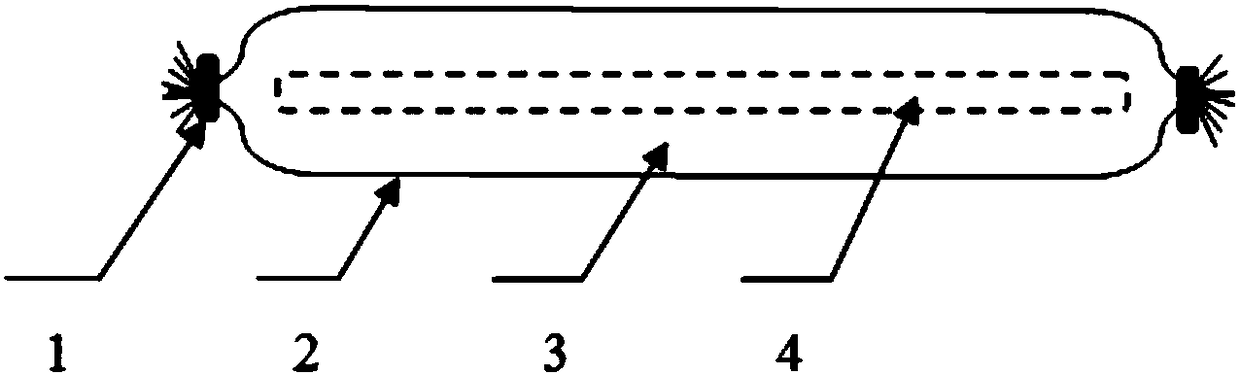

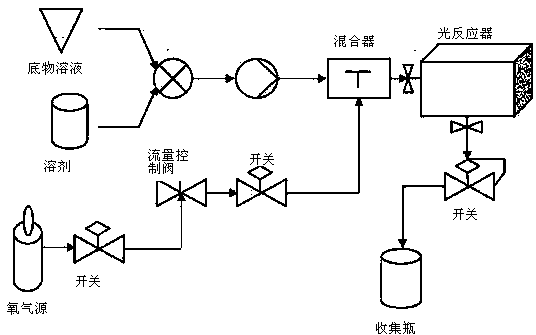

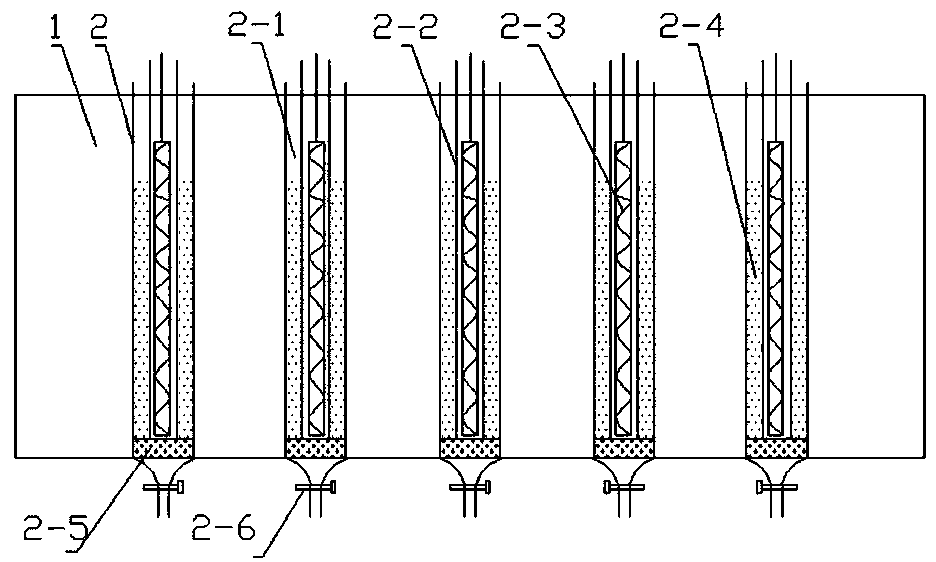

Method and equipment for scale production of artemisinin

ActiveCN103739609AHigh yieldIncrease profitOrganic chemistryEnergy based chemical/physical/physico-chemical processesArtemisininsPtru catalyst

The invention relates to a method and equipment for scale production of artemisinin. The method comprises: dissolving dihydroarteannuic acid in an organic solvent, adding a photosensitizer and an acid catalyst, adopting a light source to make the dihydroarteannuic acid be subjected to light oxidation so as to obtain peroxy alcohol of the dihydroarteannuic acid, carrying out acid catalysis so as to carry out Hock cut-off, and carrying out oxidation ring closing to produce the artemisinin, wherein the whole reaction or only the light oxidation reaction is performed in photosensitive oxidation reaction equipment. The present invention further comprises the photosensitive oxidation reaction equipment for performing the method. According to the present invention, the method has characteristics of low reaction temperature and high light source utilization rate, and the equipment has characteristics of high light source utilization rate, simple structure, low manufacturing cost, and high single-batch productivity.

Owner:HUNAN KEYUAN BIO PRODS

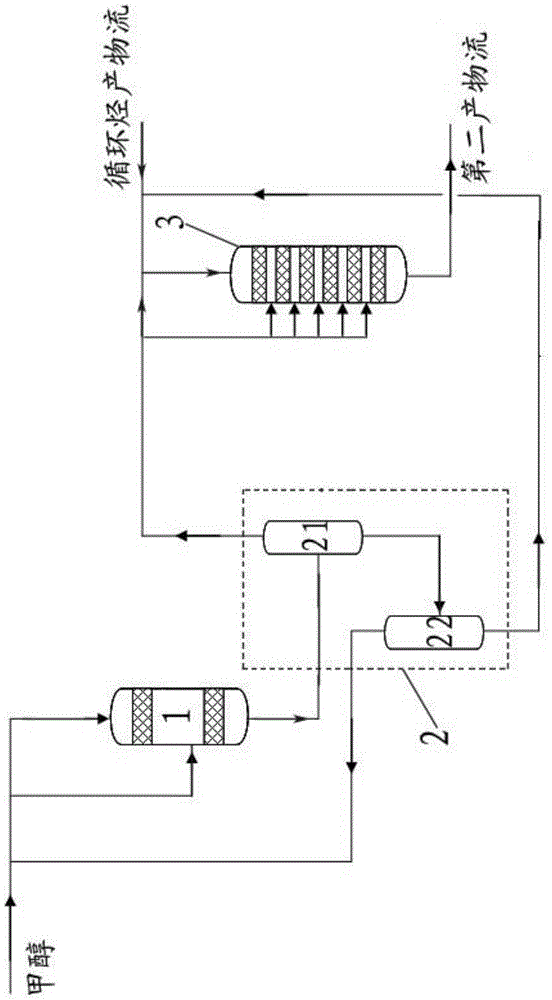

Method for preparing propylene from methanol

ActiveCN105523876AReduced Reaction TypesReduced risk of sinteringMolecular sieve catalystCatalystsReaction typeDimethyl ether

The invention discloses a method for preparing propylene from methanol. The method comprises the steps: a reaction for preparing dimethyl ether from methanol is performed with a first reactor, to obtain a first product flow including dimethyl ether, water and unreacted methanol; the first product flow is separated with a separation device, the separated methanol returns to the first reactor, and the separated dimethyl ether and water are sent into a second reactor; a reaction for preparing propylene from dimethyl ether is performed with the second reactor, to obtain a second product flow; and the second product flow is separated to obtain a cyclic hydrocarbon product flow comprising C2, C4, C5 and C6 components, and the cyclic hydrocarbon product flow is anew sent back to the second reactor. The methanol in the first product flow returns to the first reactor, so that a catalyst bed layer is easier to control, and the risk of catalyst sintering is reduced; and at the same time, the reaction types in the second reactor are reduced, so as to be more conducive to high-efficiency effect of a catalyst.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

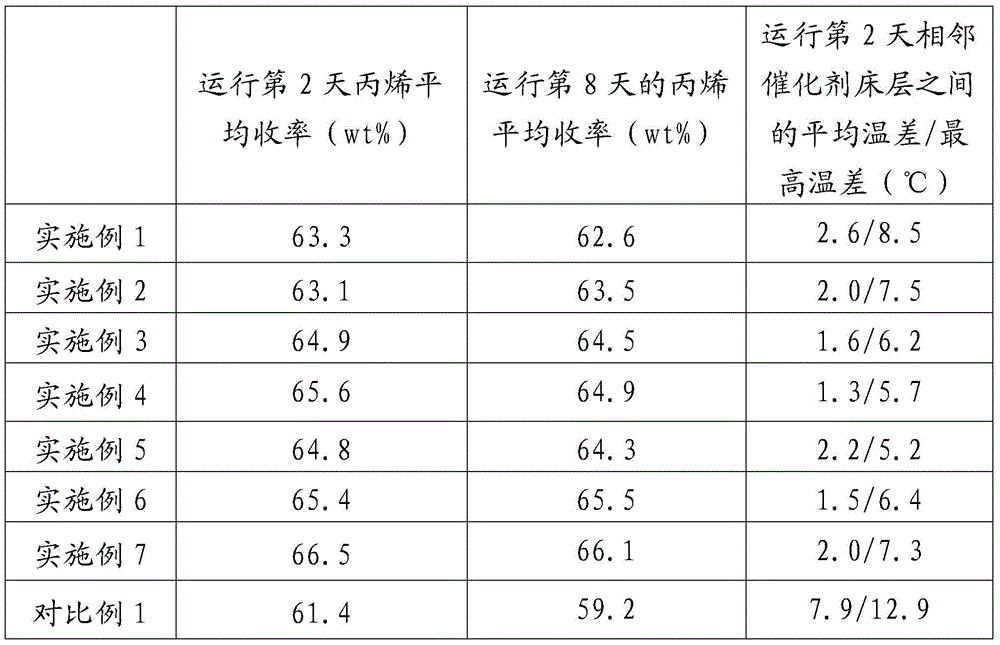

Two-section preparation process of propylene

ActiveCN102675026ARealize comprehensive utilizationShorten the separation processHydrocarbon from oxygen organic compoundsEthylene productionMolecular sievePtru catalyst

The invention discloses two-section preparation process of propylene. Methanol and refinery carbon teterolefin are used as raw materials, water is used as a diluent, and a two-section fixed bed reactor is adopted for preparation. Catalyst in the first section of the fixed bed reactor contains 50%-85% ZSM-5 molecular sieve, and catalyst in the second section of the fixed bed reactor is magnesium element modified ZSM-5 molecular sieve catalyst. By means of the two-section preparation process of the propylene, water amount in the diluent is reduced, operation temperature is reduced, propylene selectivity and P / E ratio are effectively improved, conversion rate of the raw material methanol can reach as high as 100%, conversion rate of the refinery carbon teterolefin can reach above 85%, and one-way selectivity of propylene can reach as high as 50%.

Owner:CHAMBROAD CHEM IND RES INST CO LTD

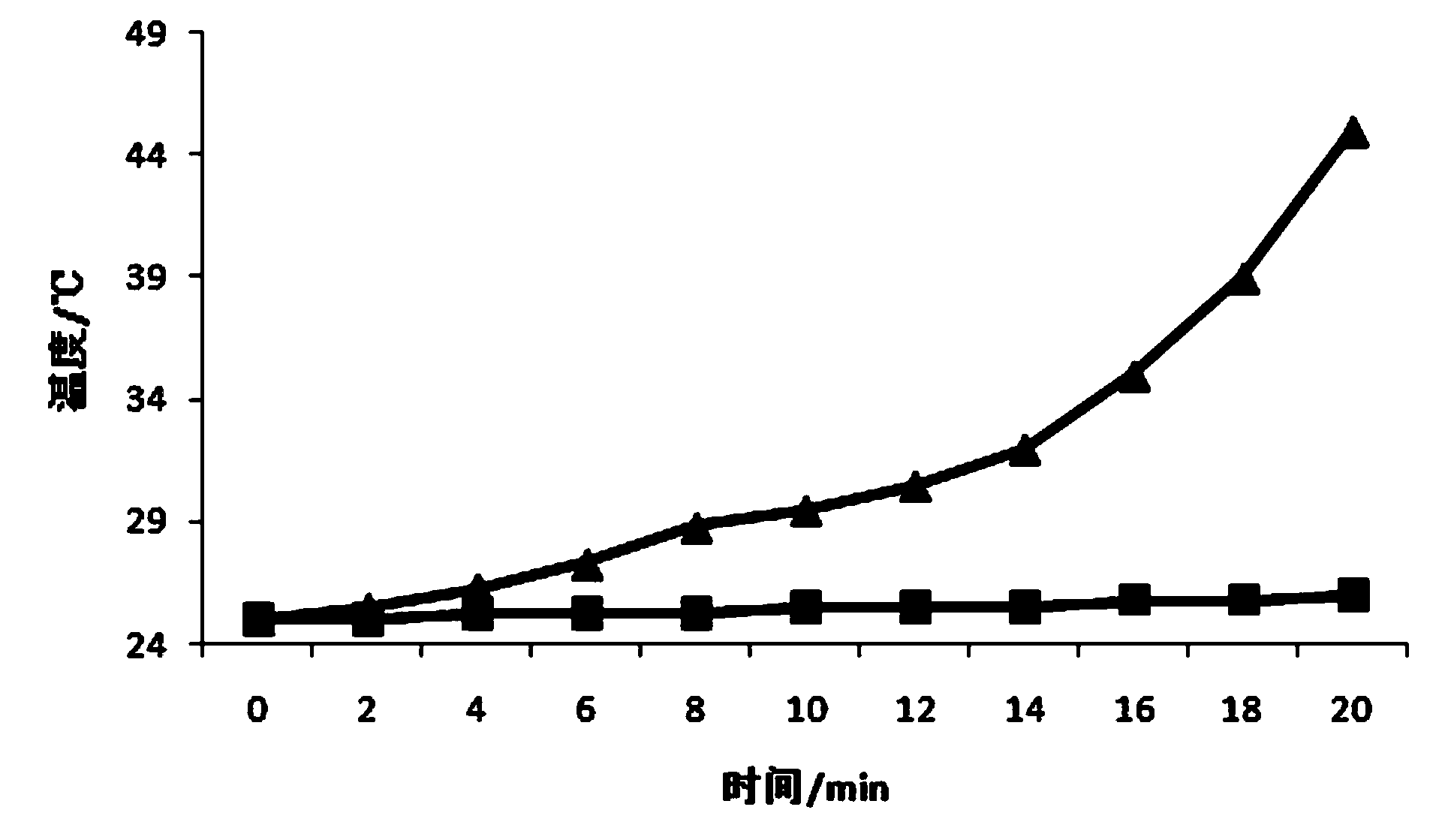

Polyurethane grouting reinforcement material and preparation method thereof

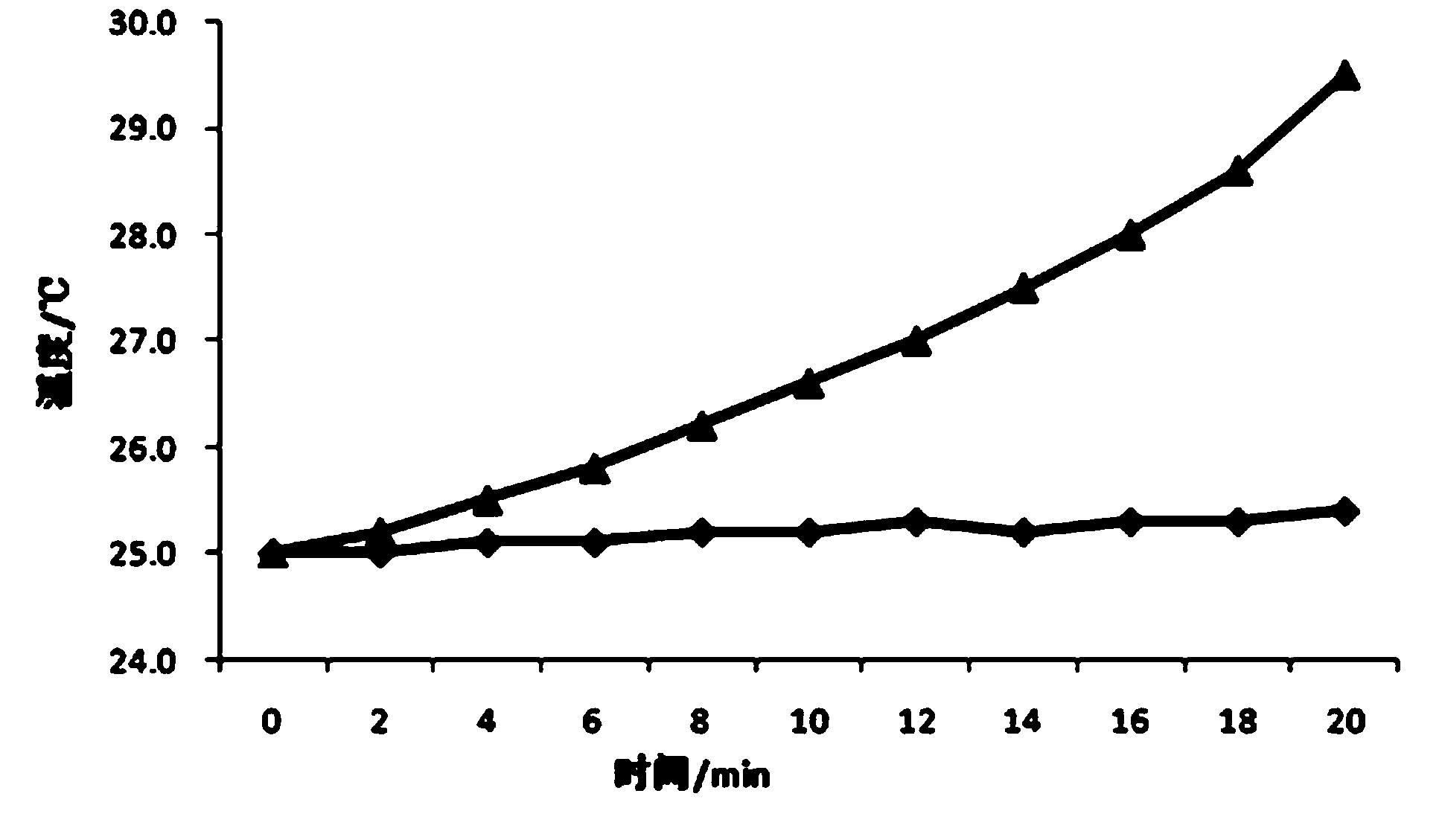

InactiveCN112143216ALow maximum reaction temperatureLow reaction temperatureHeat-exchange elementsPolymer scienceReaction temperature

According to the polyurethane grouting reinforcement material and the preparation method thereof, on the basis that the performance of an original polyurethane grouting reinforcement material is not affected, the reaction temperature of the polyurethane grouting reinforcement material in the curing process is remarkably reduced, and the constant-temperature additive is added into the polyurethanegrouting reinforcement material; the constant-temperature additive has the characteristics of self heat absorption, high energy storage and high thermal conductivity, and can absorb a large amount ofheat when polyurethane is cured to release heat, so that reaction heat storage is reduced; and the preparation method of the polyurethane grouting reinforcement material is simple, safe and environmentally friendly, industrialization is easy to achieve, and the polyurethane grouting reinforcement material has wide development prospects.

Owner:SHAANXI COAL & CHEM TECH INST

Moving bed catalytic process for preparing p-xylene by alkylating aromatic hydrocarbon

ActiveCN102372589AImprove stabilityOvercoming the Difficulty of Frequent Shutdown RegenerationHydrocarbon by isomerisationHydrocarbon by hydrocarbon and non-hydrocarbon condensationComing outAromatic hydrocarbon

The invention relates to a moving bed catalytic process for preparing p-xylene by alkylating aromatic hydrocarbon. By the moving bed catalytic process, the problems of high temperature rise of a reaction bed, insufficient stability of a catalyst and difficulty in implementing continuous production in the prior art are mainly solved. In the moving bed catalytic process, the aromatic hydrocarbon serving as a raw material and dimethyl ether serving as an alkylating reagent are subjected to mixed feeding and are conveyed to a moving bed reactor, the catalyst which is to be regenerated and comes out of the bottom of a moving bed enters a regenerator, and the regenerated catalyst returns to the moving bed reactor to be recycled. Through the technical scheme, the problems are better solved. The moving bed catalytic process can be applied to industrial production of the p-xylene by alkylating the aromatic hydrocarbon.

Owner:CHINA PETROLEUM & CHEM CORP +1

Ecological cement for plateau region

The invention discloses ecological cement for a plateau region. The ecological cement is characterized by comprising a powder material and an additive, wherein the powder material is at least one of calcareous rock, limestone, cinerite, volcanic pumice, basalt, illite, montmorillonite, feldspar, shale, kaolin, clay, wollastonite, coal gangue, silica fume and coal ashes; and the additive is at least one of halide, carbonate, sulfate, amine alkaline matter, silicate, aluminate, alkali metal hydroxide and alkaline earth metal hydroxide. The ecological cement is high in strength, the main mechanical performance index is superior to that of glass and cement, and the ecological cement is comparable with metal materials such as ceramic and aluminum steel. The ecological cement has relatively high corrosion resistance and relatively good durability and is greatly superior to a traditional cement material. The ecological cement has relatively good quick hardening and curing property, is in high temperature resistant, good in heat insulation effect, is relatively low in heat conductivity coefficient and is comparable with a light refractory clay brick.

Owner:CHONGQING LONGZHE HIGH TECH MATERIAL

A method for producing propylene from methanol

ActiveCN105523876BReduced Reaction TypesReduced risk of sinteringHydrocarbon from oxygen organic compoundsChemical recyclingEfficient catalystDimethyl ether

The invention discloses a method for producing propylene from methanol, which comprises: utilizing a first reactor to perform methanol-to-dimethyl ether reaction to obtain a first product stream; the first product stream includes dimethyl ether, water and unreacted Methanol; Utilize separation device to separate described first product flow, make separated methanol return to described first reactor, separated dimethyl ether and water send into second reactor; Utilize second reactor to carry out Dimethyl ether to propylene reaction to obtain a second product stream; the second product stream is separated to obtain a recycled hydrocarbon product stream comprising C2, C4, C5 and C6 components, and the recycled hydrocarbon product stream is returned to the Describe the second reactor. The invention returns the methanol in the first product flow to the first reactor, thereby making the catalyst bed easier to control and reducing the risk of catalyst sintering; meanwhile, reducing the types of reactions in the second reactor, which is more conducive to the high-efficiency effect of the catalyst.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Fluidized catalytic method for preparing p-xylene by alkylating toluene

ActiveCN102372583AReduce temperature riseReduce reaction exothermHydrocarbon by hydrocarbon and non-hydrocarbon condensationChemical/physical processesCatalytic methodSide reaction

The invention relates to a fluidized catalytic method for preparing p-xylene by alkylating toluene. By the fluidized catalytic method, the problems of high temperature rise of a catalyst bed, multiple side reactions of an alkylating reagent and a low utilization rate in the prior art are mainly solved. In the fluidized catalytic method, methanol, dimethyl ether and toluene are subjected to mixed feeding, and the dimethyl ether partially replaces the methanol to be used as the alkylating reagent. Through the technical scheme, the problems are better solved. The fluidized catalytic method can be applied to industrial production of the p-xylene by performing alkylation reaction on the toluene serving as a raw material.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of asymmetric cationic gemini surfactant and preparation method thereof

ActiveCN104587890BImprove surface activityGood emulsificationOrganic compound preparationTransportation and packagingSURFACTANT BLENDLong chain

The present invention provides a kind of asymmetric cationic gemini surfactant, and its molecular structure is as formula (IV), and Xˉ=Clˉ or Brˉ in the formula; And R1, R2 in the formula meet following 1) or 2): 1) R1= ‑CH3, and R2 is a long chain alkane group‑CnH2n+1, n=6~20; or R2 is a long chain alkene group‑CnH2n‑1, n=6~20; 2) R1=R2=long chain alkane group‑ CnH2n+1, n=6-12. The surfactant of the present invention contains three -OH groups in its molecule, and in aqueous solution, especially under acidic conditions, due to hydrogen bonding, the molecules are arranged more closely when they are enriched on the surface or interface. Therefore, the series of asymmetric cationic Gemini surfactants have excellent surface activity, foaming and foam stability, and emulsifying properties. Especially under acidic conditions, the emulsification stability is greatly improved.

Owner:SHANGHAI FINE CHEM CO LTD

Fluidized bed process for producing p-xylene by alkylation of aromatics

ActiveCN102372585BHigh selectivityControl feed temperatureHydrocarbon by hydrocarbon and non-hydrocarbon condensationChemical/physical processesSide reactionDimethyl ether

Owner:CHINA PETROLEUM & CHEM CORP +1

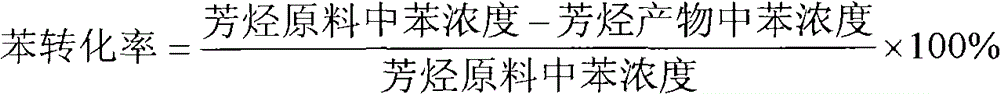

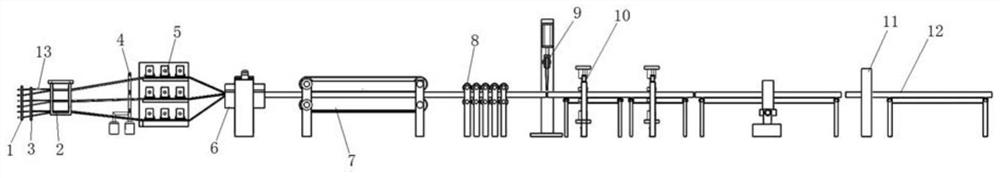

Method for continuously preparing integral composite sleeper from controllable polyurethane composite material

The invention discloses a method for continuously preparing an integral composite sleeper from a controllable polyurethane composite material. The sleeper is obtained by processing the controllable polyurethane composite material, continuous glass fibers, chopped glass fibers and a glass fiber mat, and comprises the following components in percentage by mass: 30%-40% of the controllable polyurethane composite material, 40%-60% of the continuous glass fibers, 5%-20% of the chopped glass fibers and 1%-10% of the glass fiber mat. The method can solve the problems that in the pultrusion and curing process of the polyurethane synthetic sleeper, a product is burnt and cracked, a product with a large cross section size cannot be pultruded, the size of the product cannot be switched at will, continuous automatic production cannot be achieved, the production efficiency is low, the performance of the product is defective due to the fact that early-stage foaming is fast and later-stage curing is slow in the curing and forming process, and an impregnation system cannot fully infiltrate fibers when the number of the fibers is large, it is guaranteed that product is not prone to cracking, the wettability of the polyurethane composite material and the glass fibers is better, and effective adjustment of the size of a mold cavity is achieved.

Owner:HEFEI UNIV OF TECH

A temperature-resistant epoxy glue for casting micro/ultrafiltration membrane components

ActiveCN106398616BReduce the heat of curing reactionReduce reaction exothermMacromolecular adhesive additivesEpoxy resin adhesivesFiltration membraneGlycidyl ethers

The invention discloses temperature-resistant epoxy glue for micro / ultra-filtration membrane module pouring and belongs to the technical field of epoxy adhesives. The temperature-resistant epoxy glue comprises a resin component and a curing agent component. A preparation technology includes mixing and stirring basic epoxy resin, modified epoxy resin and a defoaming agent uniformly to obtain the resin component; subjecting an aromatic amine curing agent and phenyl glycidyl ether to pre-reaction according to a specific ratio for 30-60 minutes at 60-80 DEG C, mixing a reactant with a polyether amine curing agent with stirring evenly and decreasing the temperature to the room temperature so as to obtain the curing agent component; mixing and stirring the resin component and the curing agent component according to a weight ratio of 100 to (70-85), standing, defoaming and curing at the room temperature. The temperature-resistant epoxy glue has the advantages of room-temperature curing, moderate mixing viscosity, gentle reaction heat release, high adhesive strength and high temperature tolerance and is applicable to micro / ultra-filtration membrane module pouring in the field of high-temperature separation.

Owner:BEIJING SCINO MEMBRANCE TECH

Temperature-resistant epoxy glue for micro/ultra-filtration membrane module pouring

ActiveCN106398616AReduce the heat of curing reactionReduce reaction exothermMacromolecular adhesive additivesEpoxy resin adhesivesFiltration membraneRoom temperature

The invention discloses temperature-resistant epoxy glue for micro / ultra-filtration membrane module pouring and belongs to the technical field of epoxy adhesives. The temperature-resistant epoxy glue comprises a resin component and a curing agent component. A preparation technology includes mixing and stirring basic epoxy resin, modified epoxy resin and a defoaming agent uniformly to obtain the resin component; subjecting an aromatic amine curing agent and phenyl glycidyl ether to pre-reaction according to a specific ratio for 30-60 minutes at 60-80 DEG C, mixing a reactant with a polyether amine curing agent with stirring evenly and decreasing the temperature to the room temperature so as to obtain the curing agent component; mixing and stirring the resin component and the curing agent component according to a weight ratio of 100 to (70-85), standing, defoaming and curing at the room temperature. The temperature-resistant epoxy glue has the advantages of room-temperature curing, moderate mixing viscosity, gentle reaction heat release, high adhesive strength and high temperature tolerance and is applicable to micro / ultra-filtration membrane module pouring in the field of high-temperature separation.

Owner:BEIJING SCINO MEMBRANCE TECH

A two-stage preparation process for propylene

ActiveCN102675026BRealize comprehensive utilizationShorten the separation processHydrocarbon from oxygen organic compoundsEthylene productionMolecular sievePtru catalyst

The invention discloses two-section preparation process of propylene. Methanol and refinery carbon teterolefin are used as raw materials, water is used as a diluent, and a two-section fixed bed reactor is adopted for preparation. Catalyst in the first section of the fixed bed reactor contains 50%-85% ZSM-5 molecular sieve, and catalyst in the second section of the fixed bed reactor is magnesium element modified ZSM-5 molecular sieve catalyst. By means of the two-section preparation process of the propylene, water amount in the diluent is reduced, operation temperature is reduced, propylene selectivity and P / E ratio are effectively improved, conversion rate of the raw material methanol can reach as high as 100%, conversion rate of the refinery carbon teterolefin can reach above 85%, and one-way selectivity of propylene can reach as high as 50%.

Owner:CHAMBROAD CHEM IND RES INST CO LTD

Moving bed catalytic process for preparing p-xylene by alkylating aromatic hydrocarbon

ActiveCN102372589BImprove stabilityOvercoming the Difficulty of Frequent Shutdown RegenerationHydrocarbon by isomerisationHydrocarbon by hydrocarbon and non-hydrocarbon condensationXylylenePtru catalyst

The invention relates to a moving bed catalytic process for preparing p-xylene by alkylating aromatic hydrocarbon. By the moving bed catalytic process, the problems of high temperature rise of a reaction bed, insufficient stability of a catalyst and difficulty in implementing continuous production in the prior art are mainly solved. In the moving bed catalytic process, the aromatic hydrocarbon serving as a raw material and dimethyl ether serving as an alkylating reagent are subjected to mixed feeding and are conveyed to a moving bed reactor, the catalyst which is to be regenerated and comes out of the bottom of a moving bed enters a regenerator, and the regenerated catalyst returns to the moving bed reactor to be recycled. Through the technical scheme, the problems are better solved. The moving bed catalytic process can be applied to industrial production of the p-xylene by alkylating the aromatic hydrocarbon.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com