Method and equipment for scale production of artemisinin

A large-scale technology for artemisinin, which is applied in the field of large-scale preparation of artemisinin, can solve the problems of complex operation and long reaction time, and achieve the effects of low exothermic effect, low manufacturing cost and improved utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

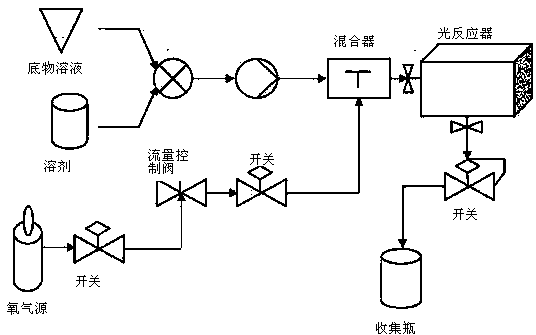

Method used

Image

Examples

Embodiment 1

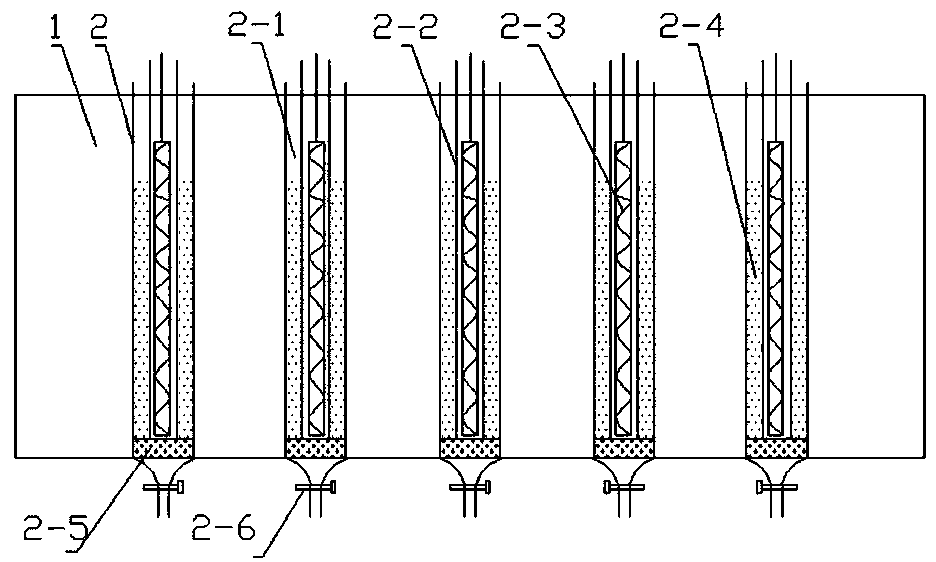

[0044] The photosensitive oxidation reaction equipment consists of a constant temperature tank 1 and ten 6L photoreactors 2. The photoreactors 2 are fixed in the constant temperature tank 1, and the light sources 2-3 used are LED light sources.

[0045] Dissolve 6Kg of dihydroartemisinic acid in 50 liters of toluene, add 2Kg of trifluoroacetic acid and 20g of tetraphenylporphyrin to it, and stir evenly; equal parts are divided into 10 parts, and added to 10 photoreactors 2 respectively ;Adjust the temperature of thermostat 1 to -30 o C. After half an hour of passing oxygen through the interface 2-6 at the bottom of the chromatography column 2-1, turn on the light source 2-3, and the reaction system is at -30 o C to react for 4 hours; then, slowly raise the reaction system to 25°C, react for another 1 hour, turn off oxygen and light source 2-3; pour the reaction solution from the reactor, and adjust the reaction system with saturated aqueous sodium bicarbonate solution To weak...

Embodiment 2

[0047] The photosensitive oxidation reaction equipment consists of a constant temperature tank 1 and twenty 6L photoreactors 2, the photoreactors 2 are fixed in the constant temperature tank 1, and the light sources 2-3 used are LED light sources.

[0048] Dissolve 10Kg of dihydroartemisinic acid in 100 liters of toluene, add 3.5Kg of trifluoroacetic acid and 35g of tetraphenylporphyrin to it, stir evenly; divide the same amount into 20 parts, and add them to 20 photoreactors in turn ;Adjust the temperature of thermostat 1 to -50 o C. After half an hour of passing oxygen through the interface 2-6 at the bottom of the chromatography column 2-1, turn on the light source 2-3, and the reaction system is at -50 o C to react for 4 hours; then, slowly raise the reaction system to 20°C, react for another 1 hour, turn off the oxygen and the light source 2-3; pour the reaction solution from the reactor, and adjust the reaction system with saturated aqueous sodium bicarbonate solution T...

Embodiment 3

[0050] The photosensitive oxidation reaction equipment consists of a constant temperature tank 1 and 20 10L photoreactors 2, the photoreactors 2 are fixed in the constant temperature tank 1, and the light sources 2-3 used are LED light sources.

[0051]Dissolve 15Kg of dihydroartemisinic acid in 150 liters of toluene, add 5Kg of trifluoroacetic acid and 60g of tetraphenylporphyrin to it, and stir evenly; equally divide into 20 parts, and add them to 20 photoreactors in turn; Adjust the temperature of constant temperature tank 1 to -20 o C. After half an hour of passing oxygen through the interface 2-6 at the bottom of the chromatography column 2-1, turn on the light source 2-3, and the reaction system is at -20 o C reaction for 4 hours; then, slowly raise the reaction system to 25°C, react for another 1 hour, turn off the oxygen and light source 2-3; pour the reaction solution from the reactor, and adjust the reaction system with saturated aqueous sodium bicarbonate solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com