Moving bed catalytic process for preparing p-xylene by alkylating aromatic hydrocarbon

A technology for the alkylation of aromatics and p-xylene, which is applied in the direction of isomerization hydrocarbon production, condensation between hydrocarbons and non-hydrocarbons, chemical recovery, etc., can solve the problems of continuous production, large temperature rise of the reaction bed, Insufficient catalyst stability and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

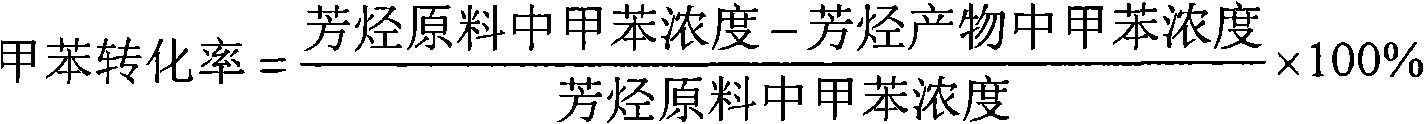

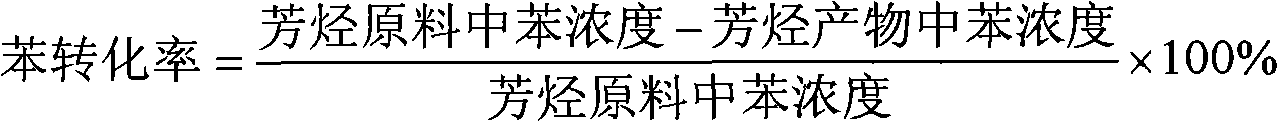

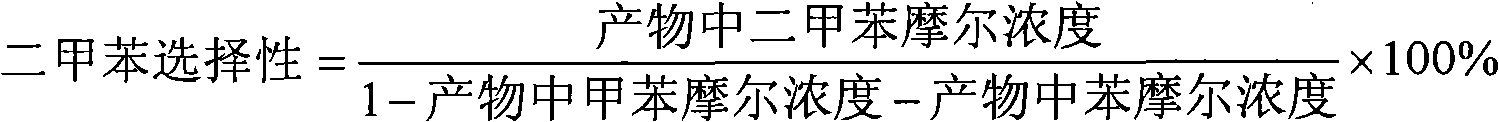

[0035] The aromatic hydrocarbon alkylation reaction was carried out according to the steps and conditions described in Comparative Example 2, but dimethyl ether was used instead of methanol as the alkylation reagent. The reaction evaluation results are listed in Table 1 for comparison.

[0036] Table 1

[0037]

Embodiment 2~5

[0039] The alkylation reaction was carried out according to the steps and conditions described in Example 1, but the catalyst regeneration conditions were adjusted. The specific regeneration conditions and reaction evaluation results are listed in Table 2 for comparison.

[0040] Table 2

[0041]

Embodiment 6~9

[0043] According to the steps and conditions described in Example 1, the aromatic hydrocarbon alkylation reaction was carried out, but the aromatic hydrocarbon feed was a mixture of benzene and toluene. The specific aromatic hydrocarbon feed ratio and reaction evaluation results were listed in Table 3 for comparison. The alkylation reagent was almost completely converted. , which will not be explained below.

[0044] table 3

[0045]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com