High-strength low-heat-release mining flame-retardant grouting reinforcement material and preparation method thereof

A grouting reinforcement, low heat release technology, applied in the field of coal and rock mass reinforcement, can solve the problems affecting normal production operations, changes in coal physical and chemical properties, and high maximum reaction temperature, and achieve improved strength, good fluidity, and low initial viscosity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

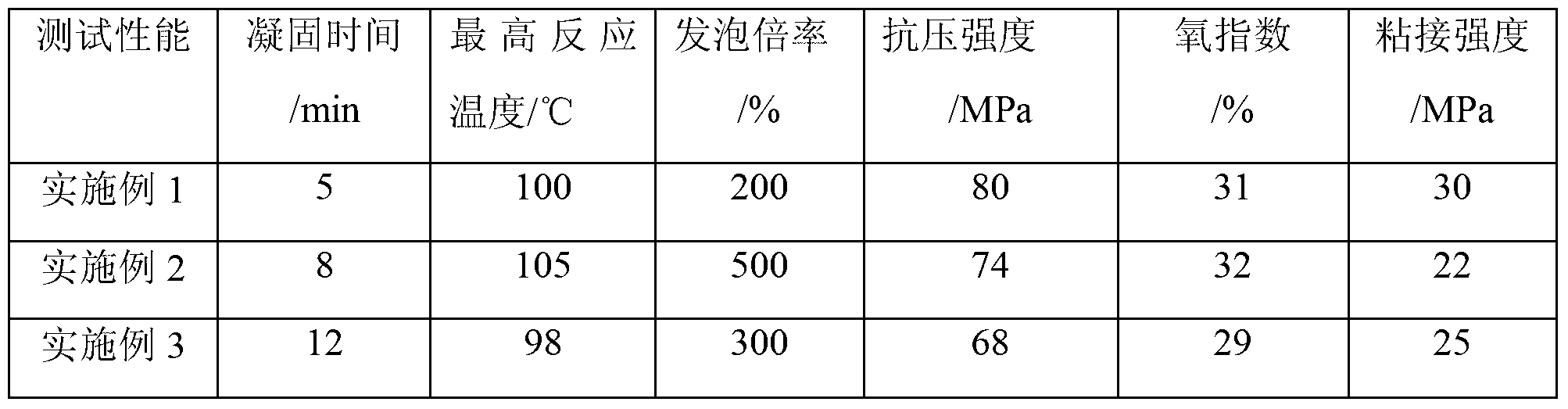

Examples

Embodiment 1

[0040] 1) Preparation of isocyanate prepolymer: Add 28 parts by mass of polyether polyol N303 into the reaction kettle, raise the temperature to 110-120°C, dehydrate for 2 hours under a vacuum degree of 5mmHg, and obtain dehydrated polyether polyol N303 ; Cool down to 60°C, remove the vacuum, add 690 parts by mass of polymethylene polyphenyl polyisocyanate Wannate PM-2025 to dehydrated polyether polyol N303, react at 50-70°C for 1-1.5 hours, stop Prepolymerization reaction to obtain isocyanate prepolymer.

[0041] 2) Preparation of mixture A: 63 parts by mass of isocyanate prepolymer in step 1), 35 parts by mass of flame retardant tris(β-chloroethyl) phosphate, 2 parts by mass of antistatic agent catafor PU Put it into the reaction kettle and stir for half an hour to discharge the material at a stirring speed of 150-250r / min to obtain the mixture A, which is ready for use.

[0042] 3) Preparation of mixture B: add 40 parts by mass of polyether polyol N303, 15 parts by mass of...

Embodiment 2

[0046]1) Preparation of isocyanate prepolymer: Add 28 parts by mass of polyether polyol N204 into the reaction kettle, raise the temperature to 110-120°C, and dehydrate for 2 hours under a vacuum degree of 5mmHg to obtain dehydrated polyether polyol; cool down to 60°C, release the vacuum, add 287 parts by mass of polymethylene polyphenyl polyisocyanate Wannate PM-2025 to dehydrated polyether polyol N204, react at 50-70°C for 1.5 hours to stop the prepolymerization reaction, and obtain isocyanate prepolymer.

[0047] 2) Preparation of mixture A: Add 70 parts by mass of isocyanate prepolymer, 28 parts by mass of flame retardant tris(β-chloroethyl) phosphate and 2 parts by mass of antistatic agent catafor PU in step 1) Stir in the reaction kettle for half an hour to discharge the material, the stirring speed is 150-250r / min, and obtain the mixture A, which is ready for use.

[0048] 3) Preparation of mixture B: Add 40 parts by mass of polyether polyol N303, 25 parts by mass of 2...

Embodiment 3

[0052] 1) Preparation of isocyanate prepolymer: Add 40 parts by mass of polyether polyol N204 into the reaction kettle, raise the temperature to 110-120°C, and dehydrate for 2 hours under a vacuum of 5mmHg to obtain dehydrated polyether polyol; cool down to 60 ℃, release the vacuum, add 327 parts by mass of polymethylene polyphenyl polyisocyanate Wannate PM-2025 into dehydrated polyether polyol N204, react at 50-70 ℃ for 1.5 hours to stop the prepolymerization reaction, and obtain isocyanate prepolymerization Polymer.

[0053] 2) Preparation of mixture A: Take 68 parts by mass of isocyanate prepolymer in step 1, 30 parts by mass of flame retardant tris(β-chloroethyl) phosphate, and 2 parts by mass of antistatic agent catafor PU into Stir in the reaction kettle for half an hour to discharge the material, the stirring speed is 150-250r / min, and obtain the mixture A, which is ready for use.

[0054] 2) Preparation of mixture B: Add 40 parts by mass of polyether polyol N303, 20 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com