A method for producing propylene from methanol

A technology for the production of propylene and methanol from methanol, which is applied in the direction of hydrocarbon production from oxygen-containing organic compounds, chemical recovery, organic chemistry, etc. It can solve the problems of difficult control of the reactor temperature, achieve high efficiency, reduce the risk of sintering, and reduce The effect of exothermic reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

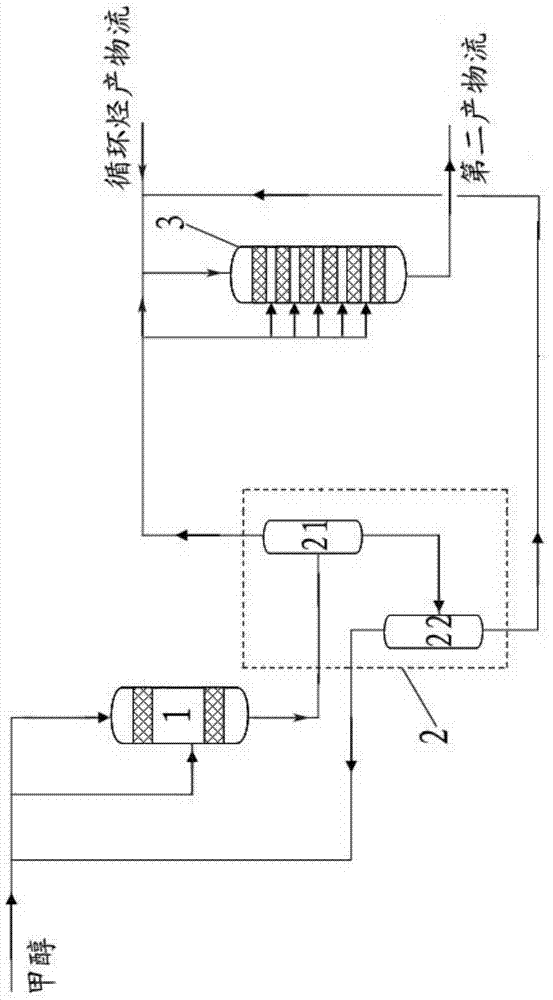

[0052] In order to evaluate the rationality of the new process based on methanol to propylene, such as figure 1 The shown model test device simulates the process conditions of industrial devices for experiments, wherein the catalyst in the first reactor (ie DME reactor) is γ-Al 2 o 3 (Select the DME-1 catalyst of Clariant Co., Ltd.), and fill in two layers. The catalyst in the second reactor is A, which is evenly packed in the first to sixth catalyst beds of the second reactor. Wherein, the feed amount of fresh methanol to the first reactor is 2.5kg / h, and the total amount of catalyst loaded in the first reactor is 1.8kg, and the reaction pressure is 0.8MPa. The total amount of catalyst loaded in the second reactor is 2.5kg, and the reaction pressure is 0.09MPa.

[0053] Fresh methanol is mixed with methanol from the top of the second distillation tower, wherein 50 wt% of the total amount of methanol is preheated to about 250 ° C, and enters from the top of the first reacto...

Embodiment 2

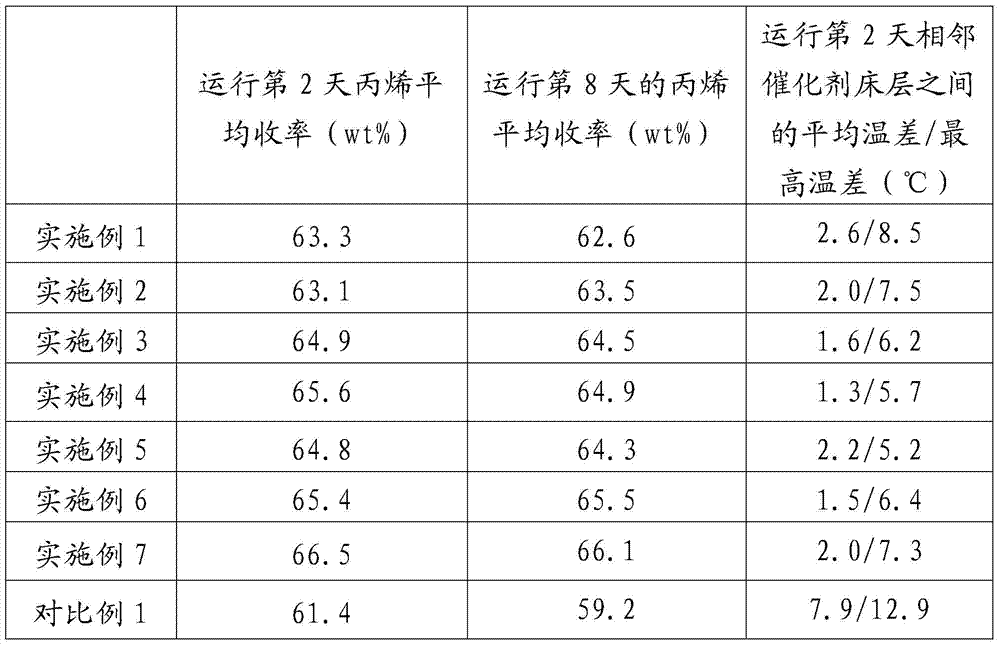

[0056] The difference from Example 1 is that the filling method of the catalyst in the second reactor is: the catalysts A and C with a mass ratio of 1:1 are evenly mixed and filled into the second reactor of the second reactor. One to sixth catalyst beds. The experimental results are shown in Table 1.

Embodiment 3

[0058] The difference from Example 1 is that the filling method of the catalyst in the second reactor is: the catalyst A is filled from the uppermost layer in the catalyst bed of the second reactor to the lower interlayer to the corresponding Catalyst bed, catalyst C is packed into the rest of the catalyst bed, and the mass ratio of catalysts A and C is 1:1. The experimental results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com