SCR (Selective Catalytic Reduction) flue gas denitration system for burning lignite

An SCR reactor and flue gas technology, applied in the field of SCR flue gas denitration system for burning lignite, can solve the problems of loss of denitration catalyst activity, high sintering risk of denitration catalyst, sintering of denitration catalyst, etc., to reduce the risk of sintering, The effect of increasing the opening degree and reducing the flue gas temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

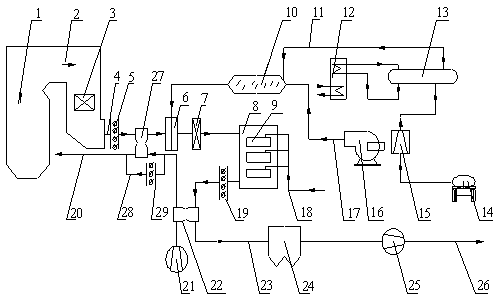

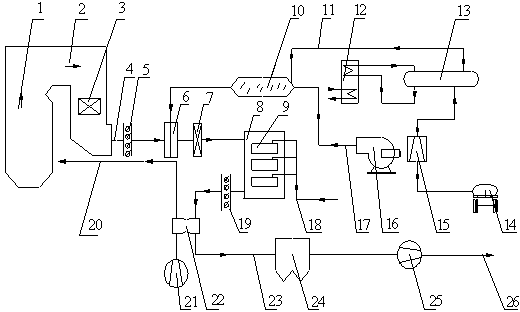

[0011] The present invention will be further described below in conjunction with the accompanying drawings, and the purpose and effect of the present invention will become more obvious.

[0012] like figure 1 As shown, the SCR flue gas denitration system for burning lignite in the present invention includes: flue gas inlet pipe 4, deflector 5, ammonia injection grid 6, static mixer 7, SCR reactor 8, ammonia / air mixer 10. Ammonia evaporator 12, ammonia storage tank 13, ammonia unloading compressor 15, air blower 16, soot blowing equipment 18, flue gas baffle 19, hot air pipe 20, fan 21, air preheater 22, electrostatic precipitator 24, Induced fan 25, high temperature air preheater 27, bypass air duct 28 and air baffle 29.

[0013] The outlet of furnace 1 is connected with horizontal flue 2 and economizer 3 in turn. The entrance of the SCR reactor 8 is connected to the economizer 3 through the flue gas inlet pipe 4, and the flue gas inlet pipe 4 is arranged in sequence with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com