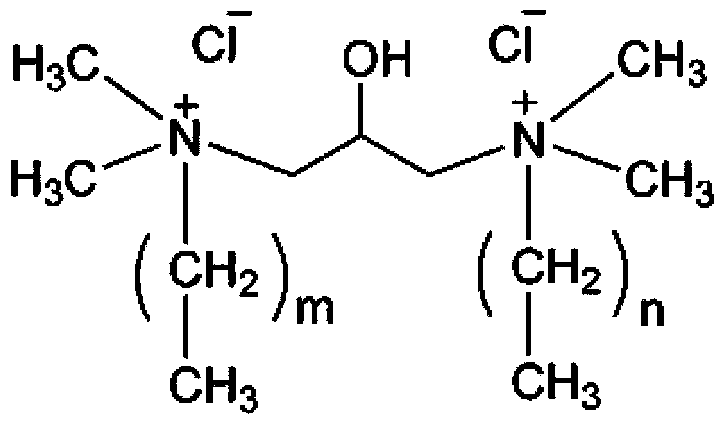

Cationic gemini surfactant preparation method

A technology of gemini surface and active agent, applied in the field of preparation of quaternary ammonium salt cation gemini surfactant, can solve the problems of corrosion of production equipment, difficulties in industrialization, adverse effects of industrialized production, etc., so as to reduce corrosion of equipment and improve reaction conversion. efficiency, and the effect of easy industrial operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1: preparation 8-3 (OH)-8 gemini cationic surfactant

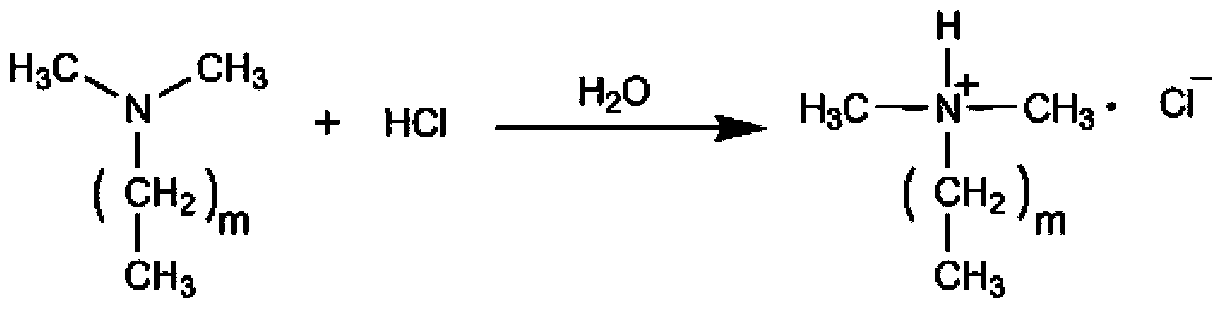

[0048] The first step: in a 1000ml flask equipped with a mechanical stirring device and a condensing reflux tube, add 157g of octyldimethyl tertiary amine, and at room temperature, pass 221.2g of a hydrochloric acid solution with a mass concentration of 15% under stirring Add the dropping funnel into the flask for 20 minutes. After adding all the hydrochloric acid solution, continue stirring for 1 hour to obtain an aqueous solution of octyldimethyl tertiary amine hydrochloride intermediate (I).

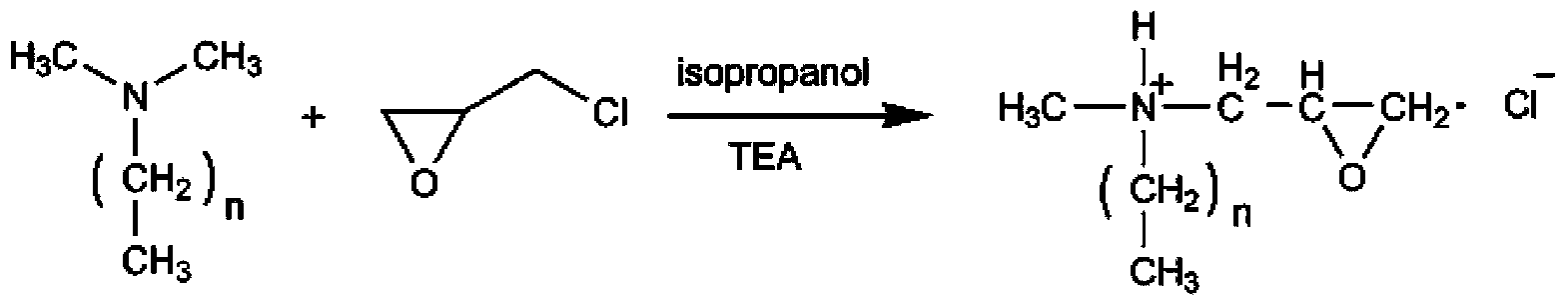

[0049] Step 2: Add 93.5g of epichlorohydrin to 157g of octyldimethyl tertiary amine in a 500ml flask equipped with a mechanical stirring device and a condensing reflux tube, raise the temperature to 70°C, react for 2 hours, then add 1.5 g of triethanolamine was continued to react for 2 h to obtain a solution of octylglyceryl dimethyl ammonium chloride intermediate (II).

[0050] The third step: in a 2000ml fla...

Embodiment 2

[0054] Embodiment 2: preparation 12-3 (OH)-18 gemini cationic surfactant

[0055] The first step: in a 1000ml flask equipped with a mechanical stirring device and a condensing reflux tube, mix 213g of dodecyldimethyl tertiary amine with 213g of deionized water, and mix 121.7g of mass under stirring at room temperature The hydrochloric acid solution with a concentration of 30% is added to the mixture of dodecyldimethyl tertiary amine and water through the dropping funnel, and the addition time is 20min. After all the hydrochloric acid solution is added, continue stirring for 0.5h to obtain dodecyldimethyl tertiary amine Tertiary amine hydrochloride (I) aqueous solution.

[0056] Second step: in the 1000ml flask that has mechanical stirring device, condensing reflux tube is housed, the octadecyl dimethyl tertiary amine of 297.6g is dissolved in the isopropanol of 119g, adds 97.1g epichlorohydrin, The temperature was raised to 85°C, and after 3 hours of reaction, 15.7 g of triet...

Embodiment 3

[0061] Embodiment 3: preparation 18-3 (OH)-18 gemini cationic surfactant

[0062] The first step: in a 2000ml flask equipped with a mechanical stirring device and a condensing reflux tube, mix 297.6g of octadecyldimethyl tertiary amine with 372g of deionized water, and mix 111.1g of it under stirring at room temperature The hydrochloric acid solution with a mass concentration of 36.5% was added into the mixture of octadecyl dimethyl tertiary amine and deionized water through the dropping funnel, and the addition time was 20 minutes. After all the hydrochloric acid solution was added, the stirring was continued for 1 h to obtain octadecyl dimethylamine Methyl tertiary amine hydrochloride (I) aqueous solution.

[0063] The second step: in a 2000ml flask equipped with a mechanical stirring device and a condensing reflux tube, dissolve 297.6g of octadecyldimethyl tertiary amine in 297.5g of isopropanol, and add 101.8g of epichlorohydrin , the temperature was raised to 80°C, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com